A kind of production method of disc type reverse osmosis membrane element

A disc-tube reverse osmosis and production method technology, which is applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of cleanliness of polluted filtered water, easy to puncture, affecting the quality of produced water and sewage treatment effect. and other problems, to achieve the effect of reducing production efficiency and cost, fast switching, and inhibiting the trend of fouling and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

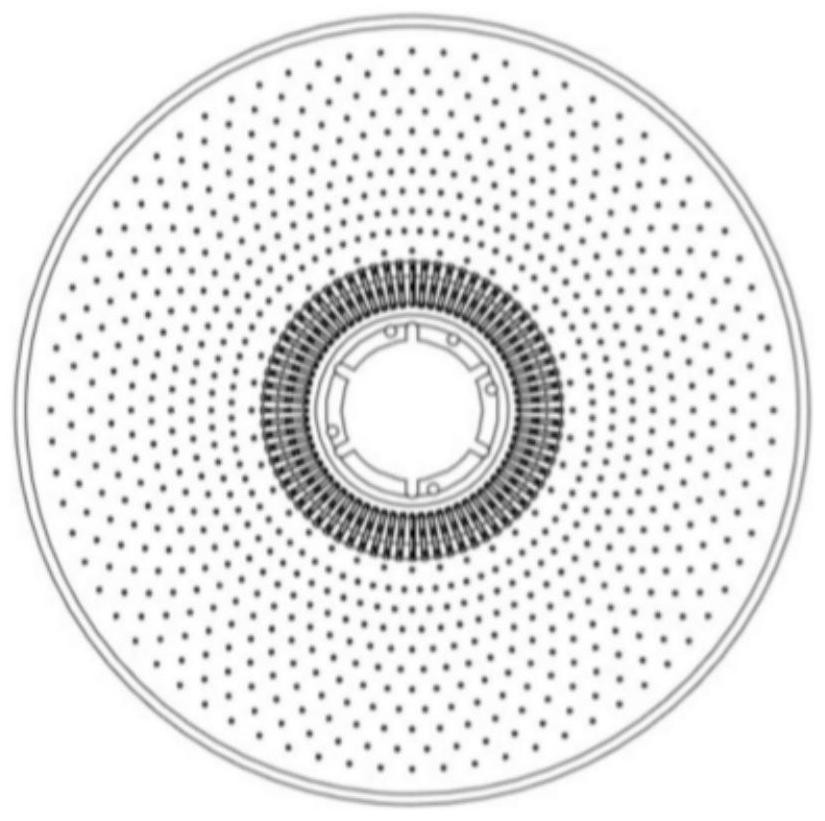

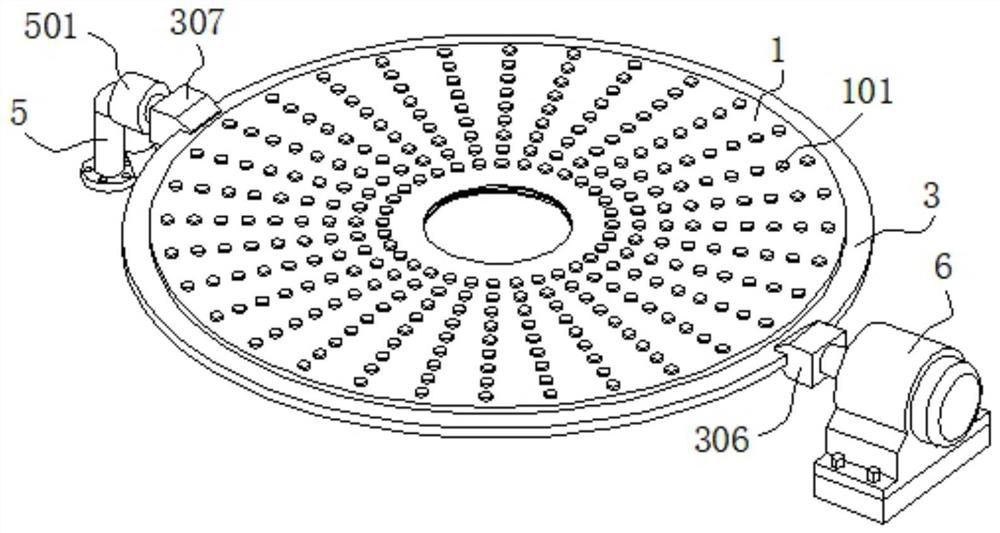

[0037] The structure of the disc tube type reverse osmosis membrane can be referred to the channel disc tube type reverse osmosis membrane module disclosed in the publication number CN109574149A, which includes a membrane shell, a central tie rod arranged in the membrane shell, a deflector plate and a membrane bag. The disc and the membrane bag are stacked and clamped in turn to form a reverse osmosis membrane. The reverse osmosis membrane is set on the central tie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com