A pressure relief and gas collection device for constant volume incendiary bombs

A technology of constant-volume incendiary bombs and gas-collecting devices, which can be used in measuring devices, internal combustion engine tests, engine tests, etc. It can solve the problems of unsatisfactory regulation and real-time change of unloading pressure, etc., and achieve the effect of high sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

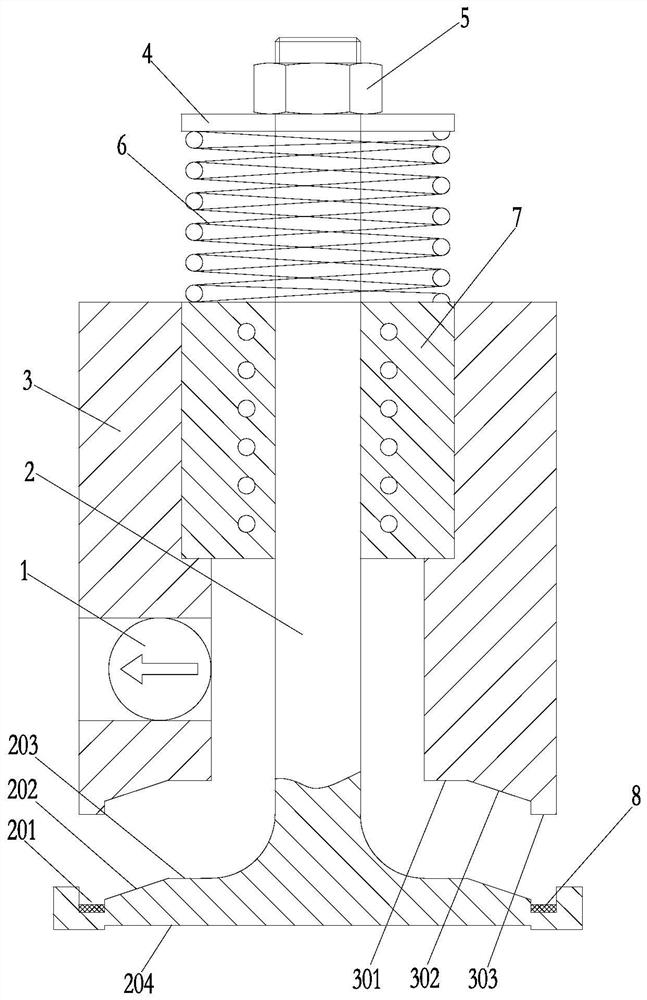

[0014] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0015] like figure 1 The shown pressure relief and gas collection device for constant volume incendiary bombs has a cylindrical base 3 made of austenitic stainless steel, and the interior of the base 3 is divided into upper, middle and lower parts. , wherein the upper and middle part of the base 3 forms a stepped through hole with a large upper and a lower small, and the lower end part of the base is a U-shaped structure, which is the function realization part of the device.

[0016] A linear bearing 7 is installed in the large hole of the step through hole of the base 3, the upper end face of the linear bearing 7 is aligned with the upper plane of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com