Aerial work platform for construction on steel beam and using method

A technology for aerial work platforms and steel beams, which is applied to the attachments of scaffolding, scaffolding supported by housing structures, and housing structure supports, etc., can solve the problem of time-consuming and laborious welding of temporary operating platforms, low safety of temporary springboards, and inconvenient disassembly and turnover. problems, to achieve the effect of convenient disassembly and assembly, high safety factor, and improved use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

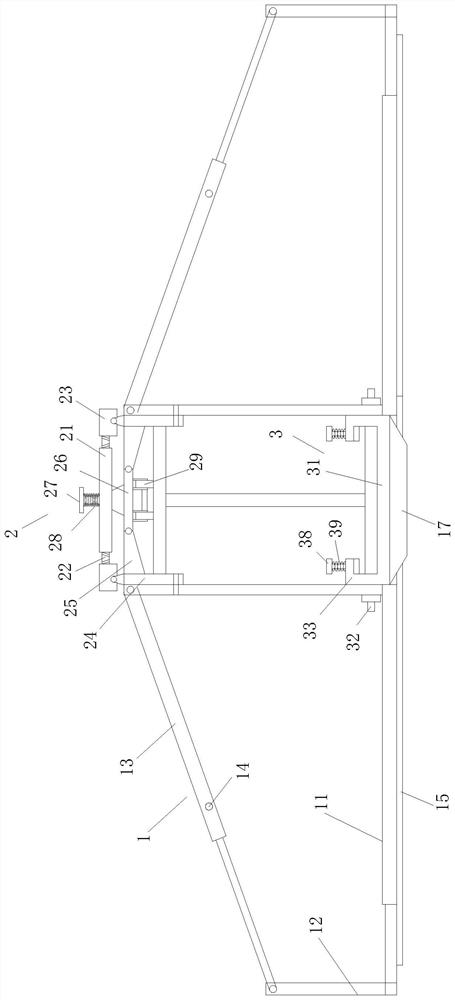

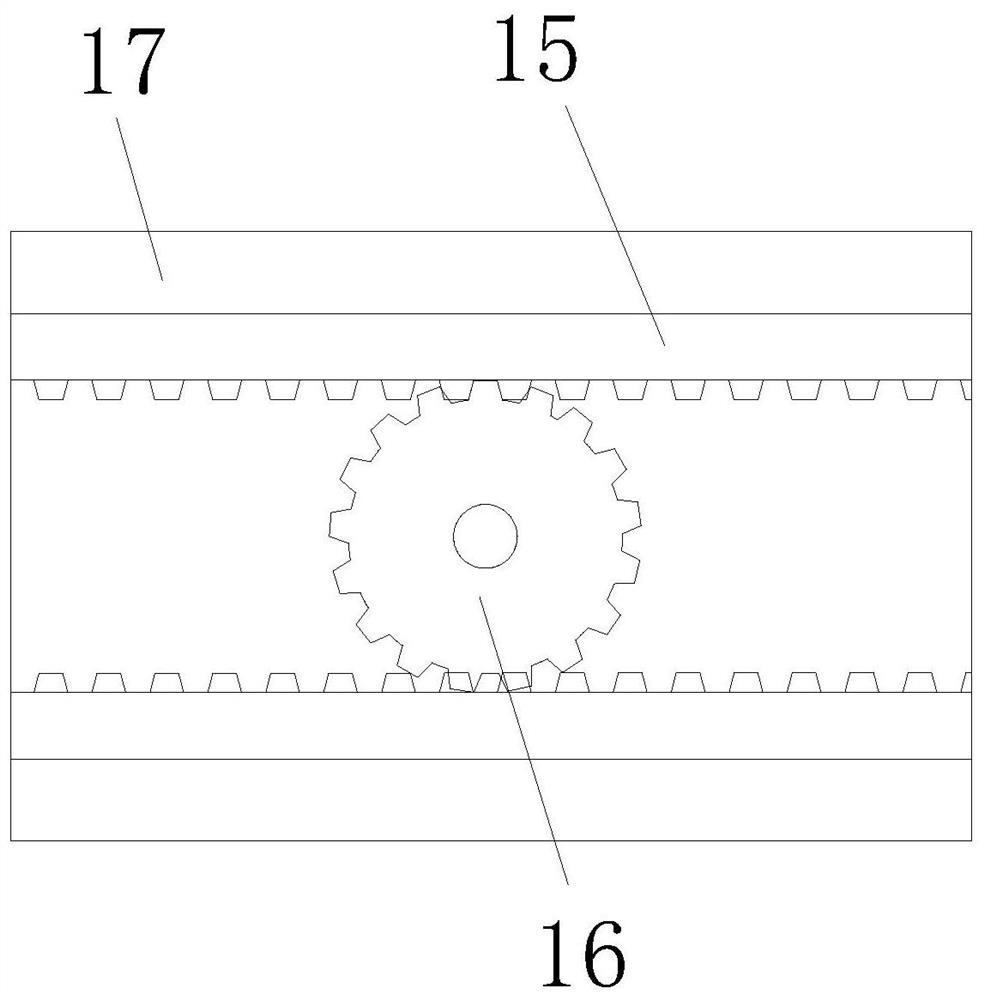

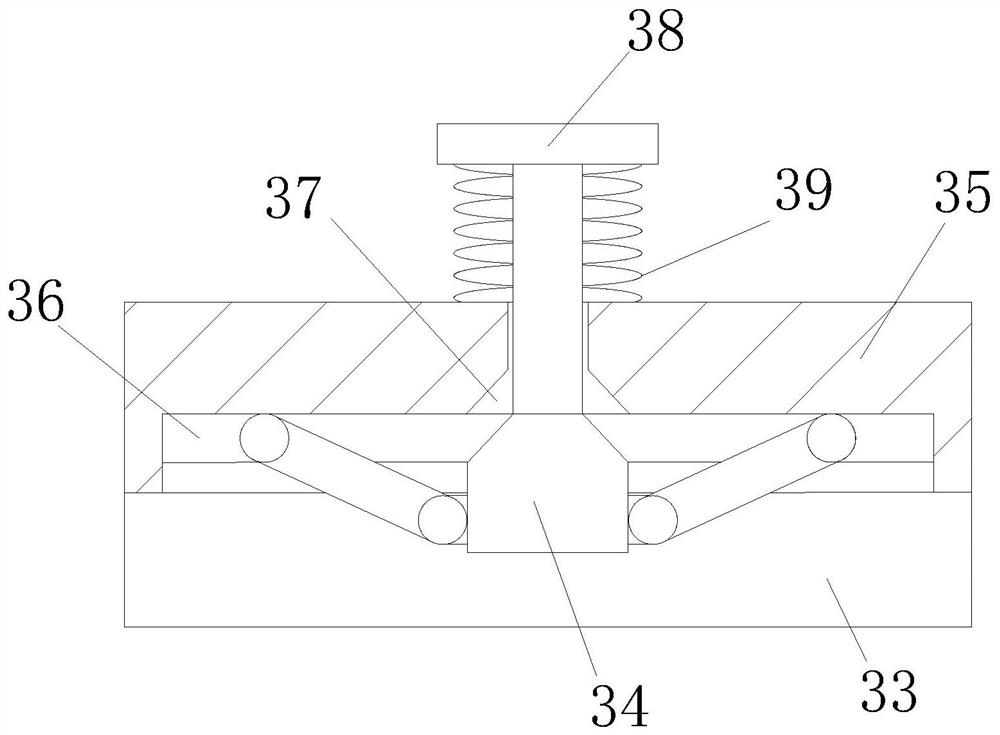

[0030] Such as Figure 1 to Figure 3 As shown, an aerial work platform used for construction on steel beams includes a frame body 1, a sliding frame 2 and auxiliary parts 3. The frame body 1 is provided with two groups symmetrically distributed on both sides of the sliding frame 2 and connected to the sliding The frame 2 is detachably connected, and the transfer of the device is realized through the detachable connection, and the installation is convenient. The bottom of the sliding frame 2 is provided with an opening and is slidably adapted to the steel beam. The auxiliary part 3 is detachably installed on the bottom of the frame body 1 And it is located at the bottom of the steel beam, and the hoop structure combined with the auxiliary part 3, the frame body 1 and the sliding frame 2 is set on the outside of the steel beam.

[0031] In a further preferred solution of this embodiment, the sliding frame 2 includes a base 21, a screw 22, a connecting seat 23, a splint 24 and a ...

Embodiment 2

[0039] A method for using an aerial work platform for construction on steel beams, comprising the following steps:

[0040] A. First, the fixing parts 11 of the frame body 1 are respectively installed on the splint 24 of the sliding frame 2, and the device is hoisted to the steel beam as a whole by hoisting, and the steel beam is located on both sides of the splint 24, and the splint 24 is on the top of the steel beam Under the combined action of the obstruction of the frame body 1 and the gravity of the frame body 1, the driving wheel 29 drives the fixed seat 26 and the positioning rod 27 to move up, and then drives the splint 24 to rotate to the side close to the steel beam, so as to realize the positioning effect of the whole device;

[0041] B. Install the auxiliary part 3 at the bottom, use the pull bolt 32 to fix the auxiliary body 31, the limit structure and the fixing part 11 of the frame body 1, and when the pull bolt 32 is connected to the fixing part 11, the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com