Land leveler and rear rack connecting structure of land leveler

A technology of connecting structure and rear frame, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem of low fatigue strength of the connecting structure of the rear frame, etc. Reliability, high flexural rigidity and strength, the effect of benefiting reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

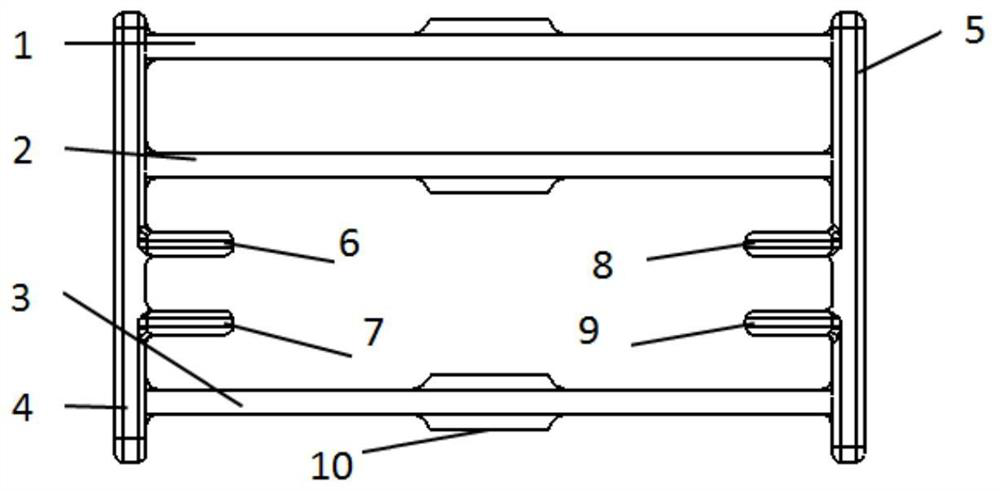

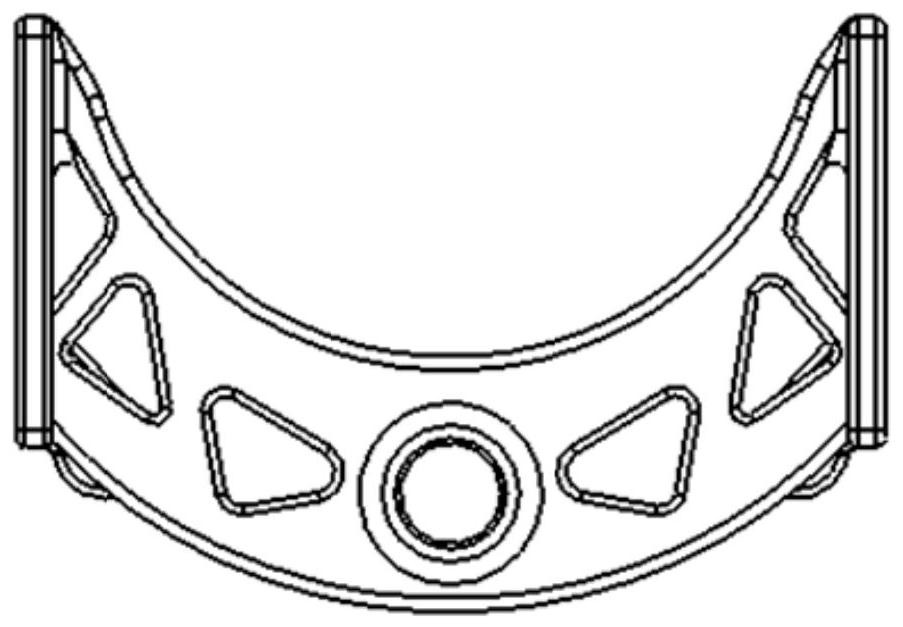

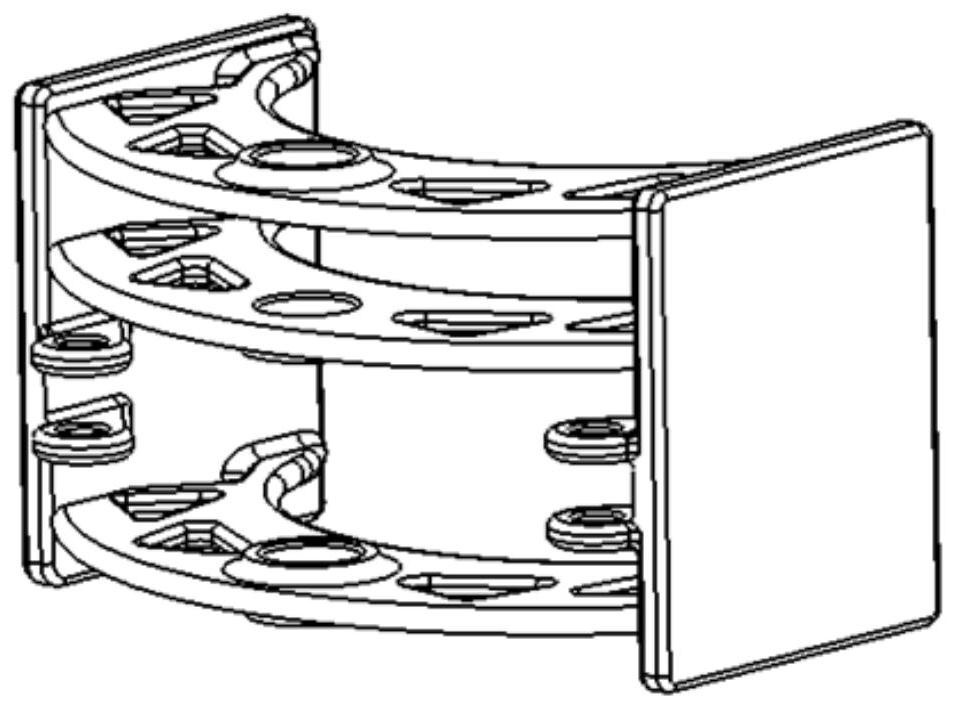

[0030] Such as Figure 1 to Figure 3 As shown, a rear frame connection structure of a grader includes a first upper hinged connection plate 1, a second upper hinged connection plate 2, a lower hinged connection plate 3, a left support plate 4, and a right support plate 5;

[0031] The left support plate 4 and the right support plate 5 are arranged vertically and parallel to each other;

[0032] The first upper hinged connecting plate 1, the second upper hinged connecting plate 2, and the lower hinged connecting plate 3 are arranged horizontally and parallel to each other from top to bottom; the first upper hinged connecting plate 1, the second upper hinged connecting plate One end of the hinged connecting plate 2 and the lower hinged connecting plate 3 is connected with the left support plate 4, and the other end is connected with the right support plate 5 to form a box structure; it is used to bear the bending resistance of the rear frame.

[0033] Corresponding positions on...

Embodiment 2

[0042] Such as Figure 5As shown, a grader includes the above-mentioned rear frame connection structure of the grader. Through the hinge pin holes 10 of the first upper hinged connecting plate 1, the second upper hinged connecting plate 2, and the lower hinged connecting plate 3, the hinge of the front frame 11 and the rear frame 12 is realized; further, turning One end of the oil cylinder is hinged with the hinge lugs on the inside of the left side support plate 4 and the right side support plate 5, and the telescopic drive of the steering oil cylinder drives the rear frame to realize turning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com