Process for treating fly ash by adopting purified waste acid

A technology for waste acid treatment and fly ash, which is applied in the direction of protection devices against harmful chemicals, etc., and can solve the problems of combined treatment of waste acid and fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

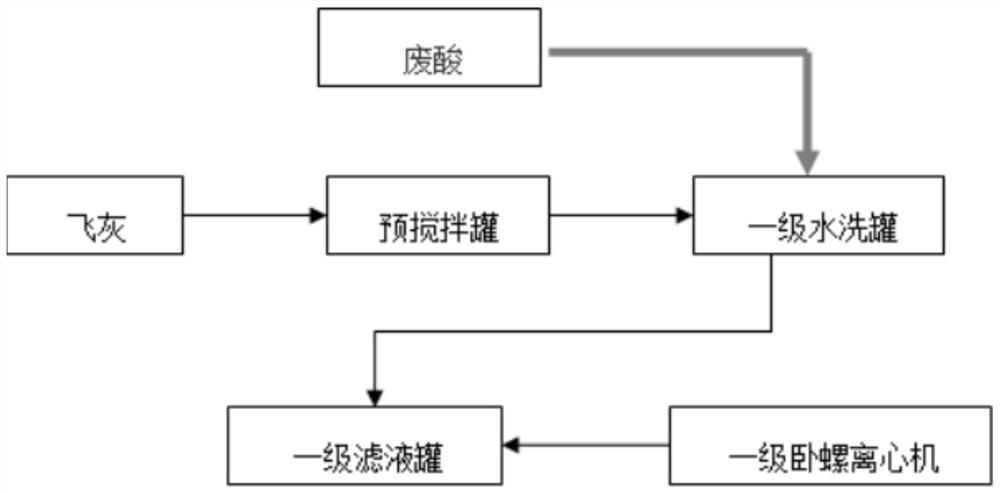

Method used

Image

Examples

Embodiment 1

[0104] This embodiment provides a process for treating fly ash with waste acid after purification, including the following steps:

[0105] (1) Mix fly ash and water according to the weight ratio of 1:2.8, stir for 30min under the condition of 100r / min, and get the slurry after stirring evenly;

[0106] (2) Adopt diffusion dialysis membrane technology to purify waste sulfuric acid, waste sulfuric acid is added in the slurry gained in step (1) with the flow rate of 300L / h after purification, wherein waste sulfuric acid accounts for 7wt.% of fly ash weight, fully reacts, get the reaction solution;

[0107] (3) The reaction solution obtained in step (2) was subjected to suction filtration for 5 minutes to obtain a filter cake and a filtrate.

Embodiment 2

[0109] This embodiment provides a process for treating fly ash with waste acid after purification, including the following steps:

[0110] (1) Mix the fly ash and water according to the weight ratio of 1:3.2, stir for 40min under the condition of 120r / min, and get the slurry after stirring evenly;

[0111] (2) Adopt diffusion dialysis membrane technology to purify waste sulfuric acid, waste sulfuric acid is added in the slurry gained in step (1) with the flow rate of 350L / h after purification, wherein waste sulfuric acid accounts for 8wt.% of fly ash weight, fully reacts, get the reaction solution;

[0112] (3) The reaction solution obtained in step (2) was subjected to suction filtration for 6 minutes to obtain a filter cake and a filtrate.

Embodiment 3

[0114]This embodiment provides a process for treating fly ash with waste acid after purification, including the following steps:

[0115] (1) Mix the fly ash and water according to the weight ratio of 1:3, stir for 35min under the condition of 110r / min, and get the slurry after stirring evenly;

[0116] (2) Use diffusion dialysis membrane technology to purify waste sulfuric acid, add waste sulfuric acid in the slurry obtained in step (1) with the flow rate of 325L / h after purification, wherein waste sulfuric acid accounts for 7.5wt.% of fly ash weight, fully react , get the reaction liquid;

[0117] (3) Suction filter the reaction liquid obtained in step (2) for 5.5 min to obtain a filter cake and a filtrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com