An optical fiber active connector

A technology of active connectors and optical fibers, applied in light guides, optics, instruments, etc., can solve the problems of difficult alignment and easy forgetting of optical fiber alignment, and achieve the effects of avoiding forgetting to lock, lowering quality requirements, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

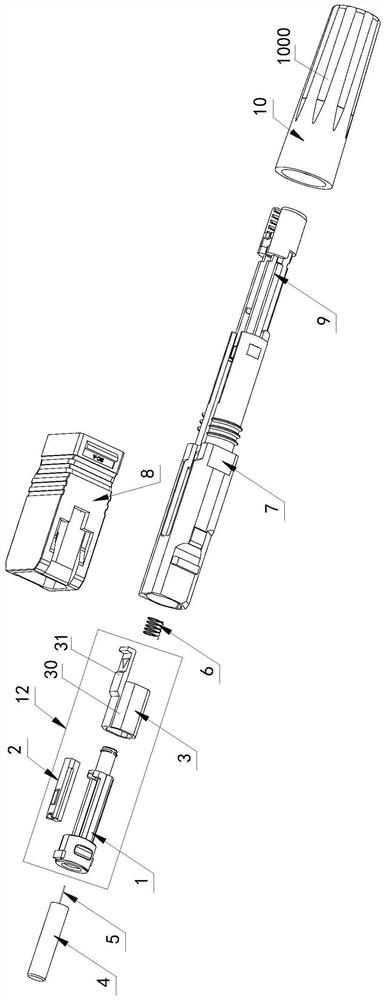

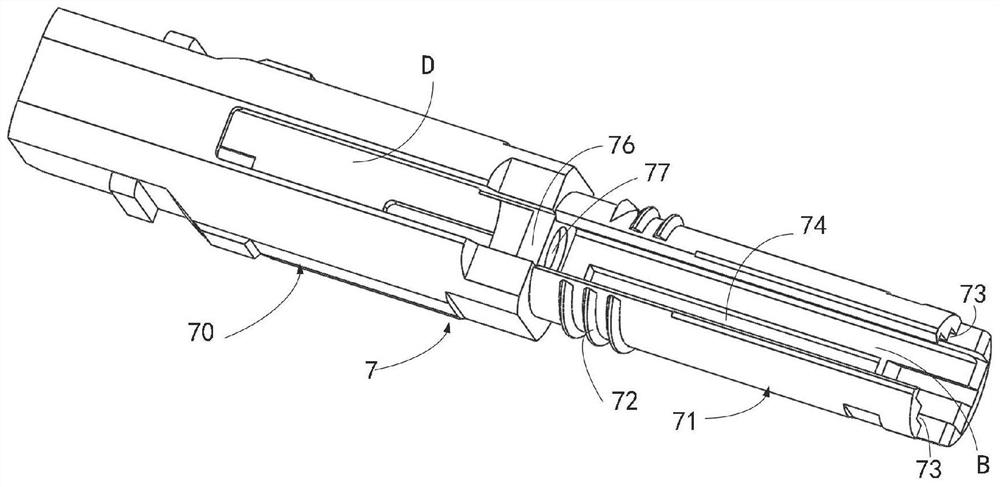

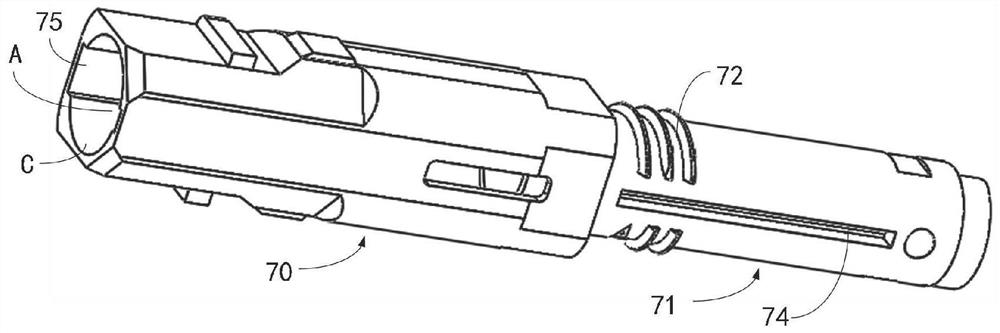

[0069] An embodiment of the present invention provides an optical fiber active connector, which can be directly terminated on site, see figure 1 As shown, the head end of the main body 7 of the hollow structure is provided with an optical fiber ferrule 4. The optical fiber ferrule 4 can be formed of ceramics, glass, plastic or metal materials to support the embedded optical fiber 5 inserted and fixed therein. The outer shell 8 can be Detachably set outside the main body 7, the main body 7 and the shell 8 are configured to have SC (snap-in square connector) type interfaces, and optical fiber field event connectors with other standard types of interfaces can also be provided, such as ST (card Connecting round head) type interface, FC (round threaded connector) type interface or LC (similar to SC joint, smaller than SC joint) type interface; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com