Novel wire clamping device wire pressing mechanism

A thread gripper and thread crimping technology, which is applied in the field of new thread gripper crimping mechanism, can solve problems such as thread gripper looseness, thread supply of thread take-up lever is small, affect work efficiency, etc., achieve uniform force balance, improve Improve embroidery quality and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

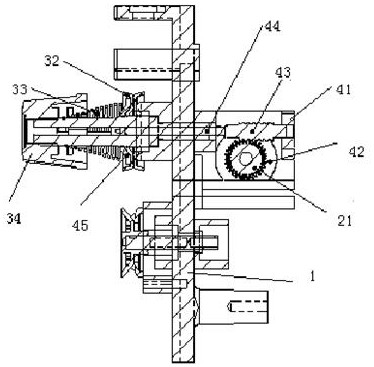

[0025] Such as Figure 1-4 As shown, the present invention is a novel wire clamp mechanism, including a wire clamp seat 1, characterized in that it also includes a control device, a wire clamp structure, and an adjustment device connected to the control device. The present invention drives the turbine 42 through the micro-motor 21 and connects the worm 43. The worm 43 will produce a slight movement distance before and after. At the moment of thread trimming, the micro-motor 21 is electronically controlled to drive the ejector rod main body 44 to release the pressure of the clamping bowl 32, so that the upper thread can be pulled out 30-55MM thread smoothly, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com