Flexible assembly platform and preparation method thereof

A platform and flexible technology, applied in the field of flexible assembly platform and its preparation, can solve the problems of non-flammability, hidden dangers of safe operation and maintenance, etc., and achieve the effects of long service life, convenient construction and installation, and good anti-wind and wave effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

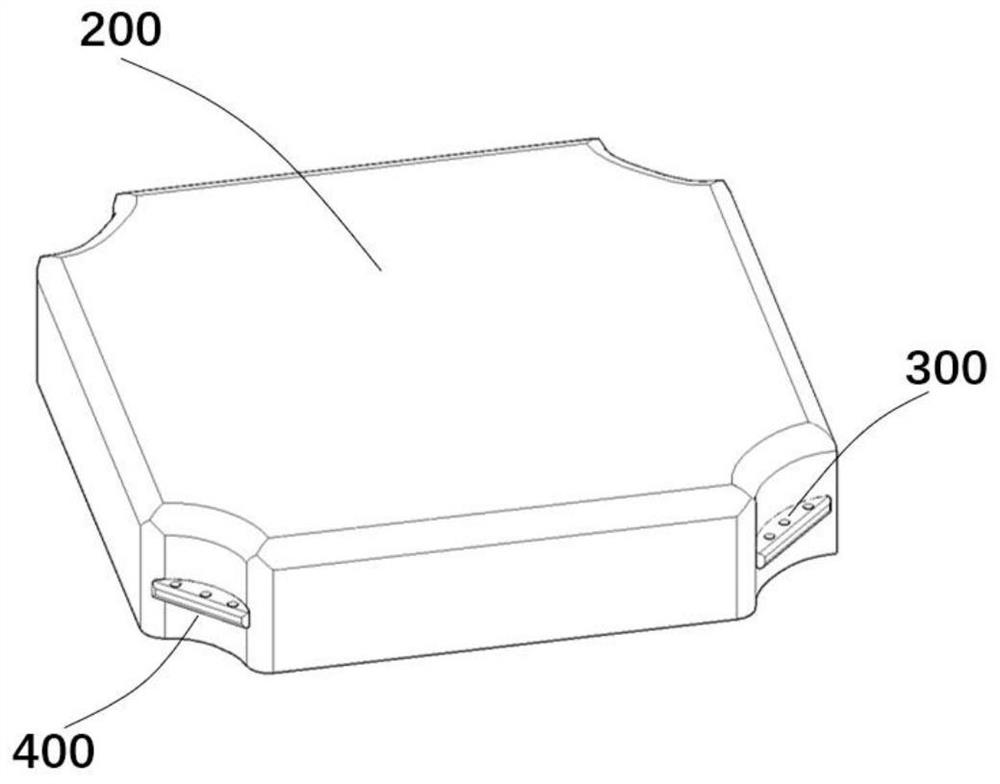

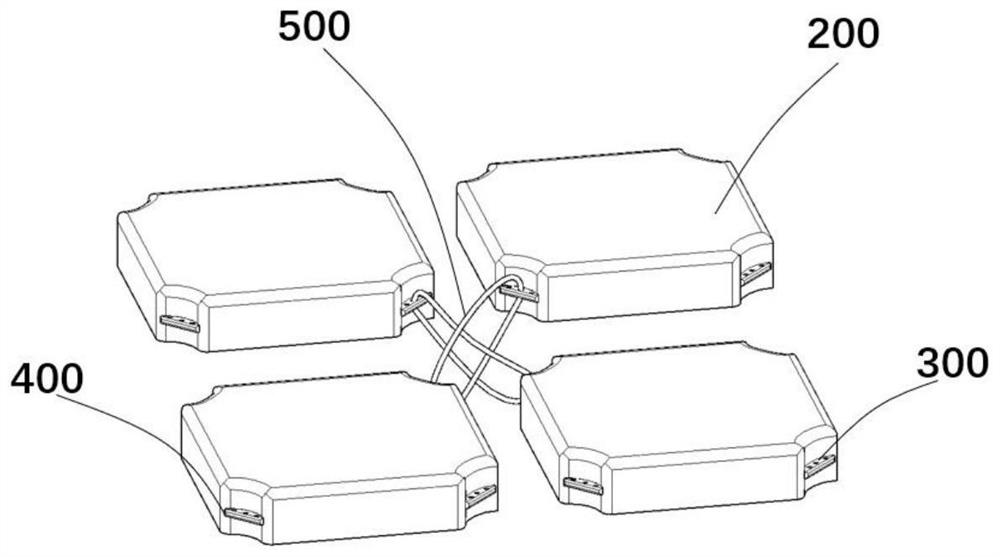

[0026] The invention provides a flexible assembly platform and a preparation method thereof, such as figure 1 with figure 2 As shown, the flexible assembly platform includes a square box buoy 200 and a connector 500, and the square box buoy 200 is (800~1200)×(800~1200)×(200~600)mm 3 The four corners of the square box buoy 200 have connecting ear bodies 400, the connecting ear body 400 is integrated with the square box buoy 200, and each connecting ear body 400 is distributed with three through connecting ear holes 300 , using engineering plastics as the main material of the square box buoy 200 with a hollow box structure, HDPE polyethylene is preferred, the wall thickness of the square box buoy 200 is 3-10mm, and the connecting part 500 is made of a flame-retardant hasp lock or a flame-retardant Composed of burning ropes, the other box-type buoy 200 is cured and reinforced by glass fiber cloth and resin glue, or the other box-type buoy 200 is sprayed with flame-retardant pai...

Embodiment 1

[0032] First prepare a size of 1000×1000×500mm 3 The square box buoy module unit, the four corners of the square box buoy have connecting ear bodies, the connecting ear body and the square box buoy are integrated, and each connecting ear body is distributed with three through connecting ear holes. The hollow square box buoy is prepared from HDPE polyethylene. The wall thickness of the square box buoy is 4mm. The connector is composed of a flame-retardant buckle lock. and connectors can be prepared with an area of 350m 2 The four edges of the large-area floating body are fixed with 8 steel anchors to prevent the impact of strong winds and waves, and to reinforce the large-area floating platform on the water.

Embodiment 2

[0034] Prepare a square box buoy with a size of 900×900×400mm 3 The square buoy module unit has connecting ears at the four corners of each square box buoy, and the connecting ears are integrated with the square box buoy. Modified PP polypropylene is used as the main material of the hollow box-type buoy. The wall thickness of the box-type buoy is 5mm. The connecting parts are composed of flame-retardant ropes. Using square box buoys and connectors can prepare an area of 300m 2 The four edges of the large-area floating body are fixed with 16 steel anchors to prevent the impact of strong winds and waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com