Miniaturized image sensor

An image sensor and photoelectric conversion technology, which is applied in image communication, TV, color TV parts, etc., can solve the problem of small shooting range of image sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

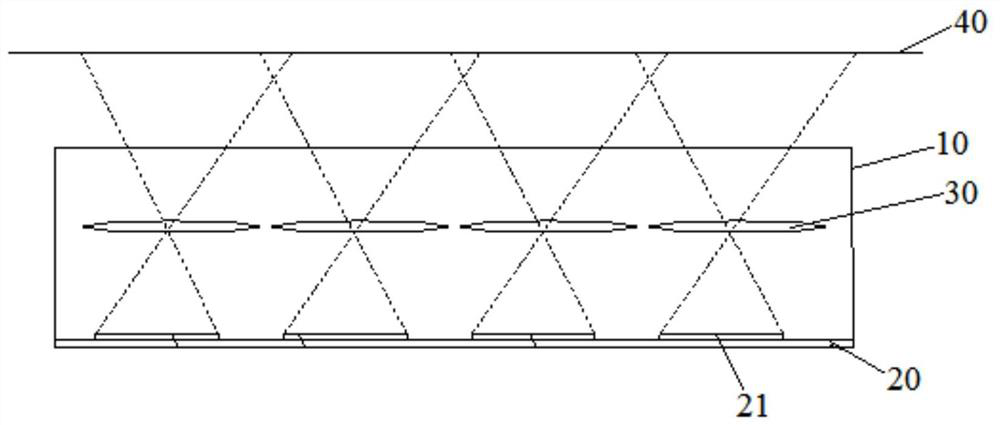

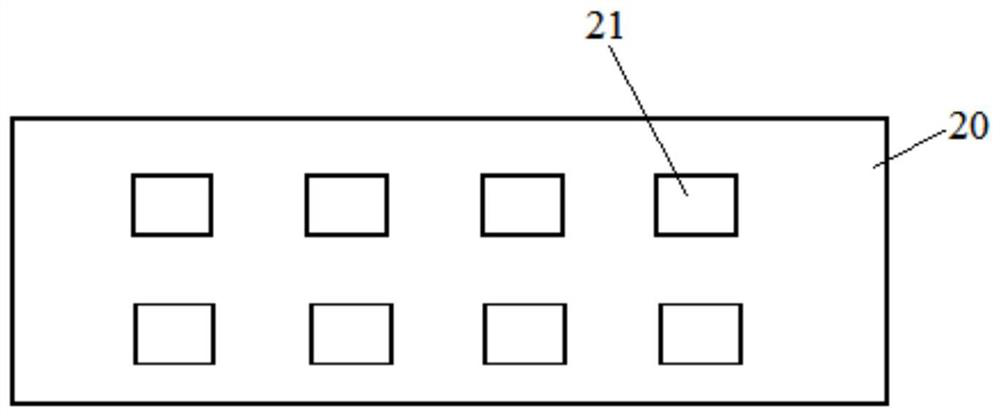

[0033] Such as Figure 1 to Figure 4 As shown, a plurality of photoelectric conversion chips 21 are arranged in a rectangular array. A plurality of photoelectric conversion chips 21 are arranged in a matrix array, so as to facilitate the arrangement of a plurality of photoelectric conversion chips 21 , so that the scanning range of the plurality of miniaturized image sensors in all directions is relatively large.

[0034] It should be noted that the miniaturized image sensor in this embodiment is suitable for scanning some objects whose length and width are almost as large.

[0035] It should be noted that the distance between any two adjacent photoelectric conversion chips 21 may be the same, and such arrangement facilitates the arrangement of the photoelectric conversion chips 21 . Of course, it is also possible that the intervals between the photoelectric conversion chips 21 in one row are the same, and the intervals between the photoelectric conversion chips 21 in differe...

Embodiment 2

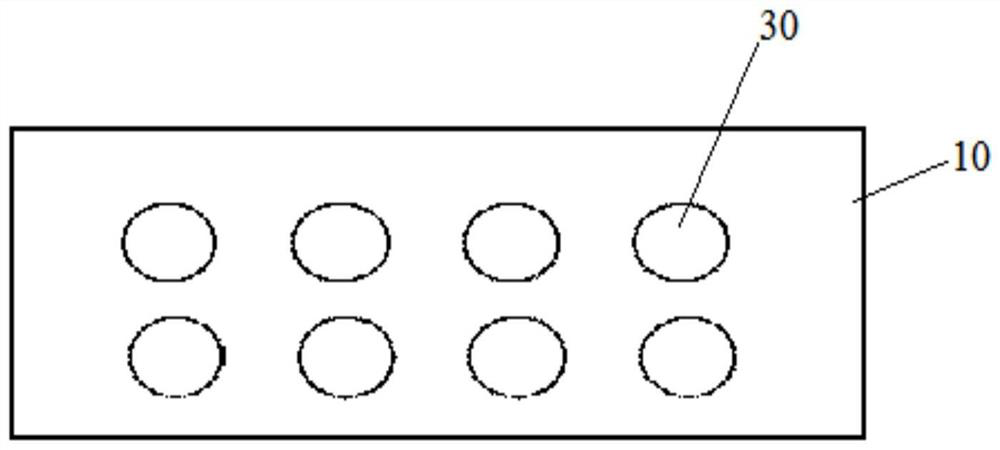

[0047] The difference from Embodiment 1 is that the arrangement of the photoelectric conversion chips 21 is different.

[0048] Such as Figure 5 with Figure 6 As shown, the photoelectric conversion chips 21 in two adjacent rows of photoelectric conversion chip rows are misaligned. Such arrangement can increase the scanning range of the miniaturized image sensor and make the structure of the miniaturized image sensor smaller.

[0049] exist Figure 5 In the specific embodiment shown, the distance between two adjacent photoelectric conversion chips 21 in the same row is the same, which can ensure the resolution of the miniaturized image sensor.

[0050] exist Figure 5 In the specific embodiment shown, the distance between two adjacent photoelectric conversion chips 21 in the same row is greater than the distance between two adjacent photoelectric conversion chips 21 in two adjacent rows. Such arrangement is beneficial to miniaturization of the miniaturized image sensor u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com