Method for predicting residual service life of rolling bearing based on linear reliability index

A rolling bearing and reliability technology, applied in the field of rolling bearing reliability evaluation, can solve the problems of weak remaining service life representation performance, affecting remaining life prediction accuracy, and low correlation degree of health indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

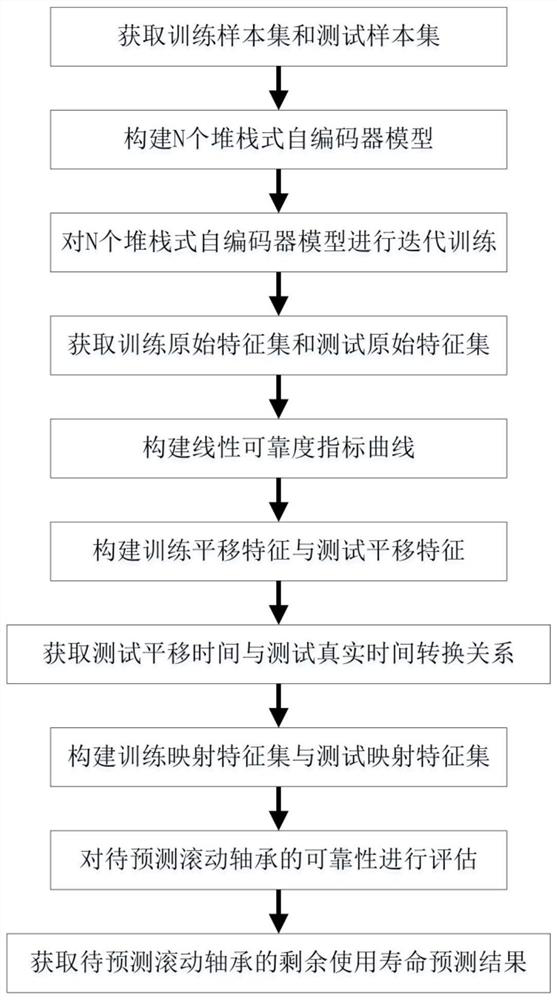

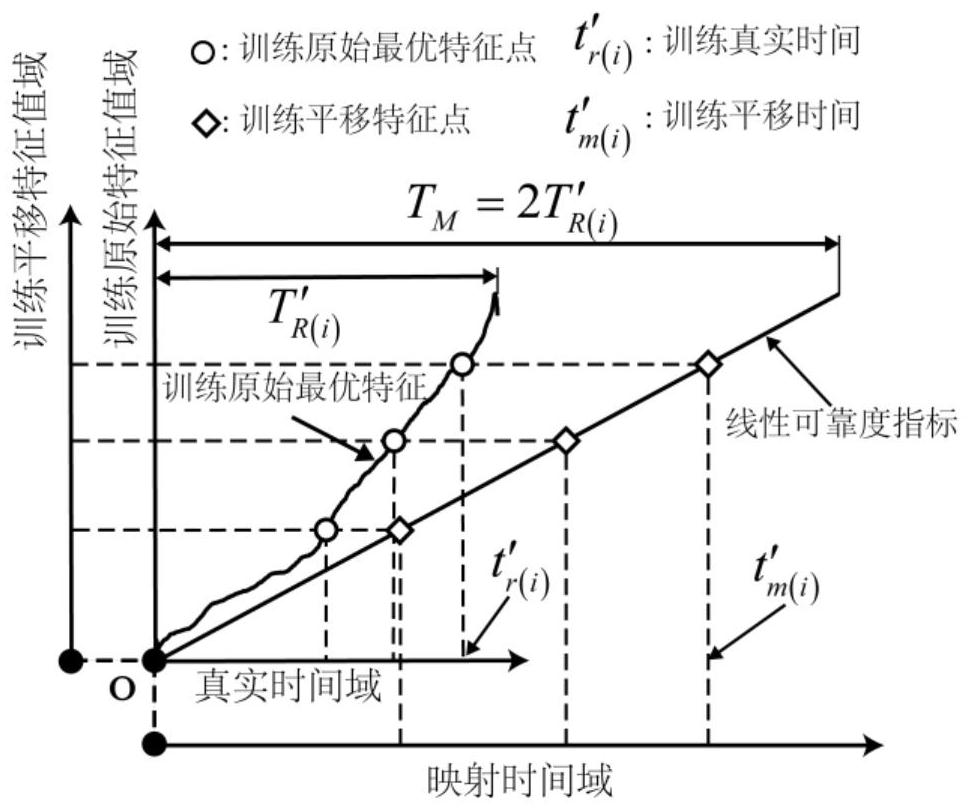

[0049] refer to figure 1 , the present invention comprises the steps:

[0050] Step 1) Obtain the training sample set X train and the test sample set X test :

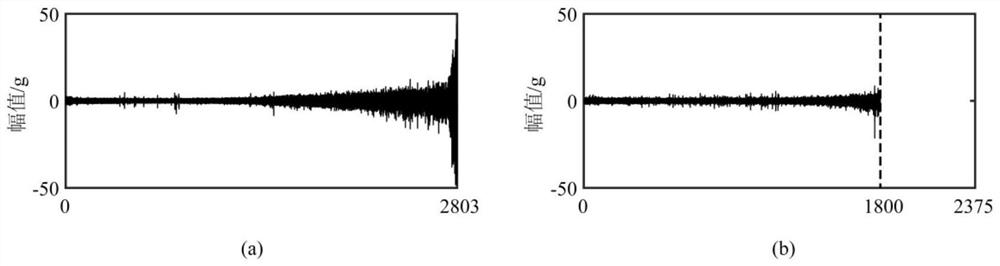

[0051] The vibration time domain signals used in this embodiment all come from the bearing vibration time domain signals collected by the bearing accelerated life test rig PRONOSTIA. The platform is mainly composed of speed sensor, temperature sensor, asynchronous motor, pressure sensor and NIDAQ data acquisition card. Among them, two accelerometer sensors are installed at the horizontal and vertical positions of the bearing to monitor the vibration of the bearing. The sampling frequency of the accelerometer is 25.6 kHz every 10 seconds, and the sampling duration is 0.1 seconds. There are three different working conditions: the first (speed 1800rpm, load 4000N), the second (speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com