Multi-station data acquisition and processing system of flow assembly line

A data acquisition and processing, assembly line technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as employees being unable to keep up with reasonable progress, lack of monitoring and data collection methods, and cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

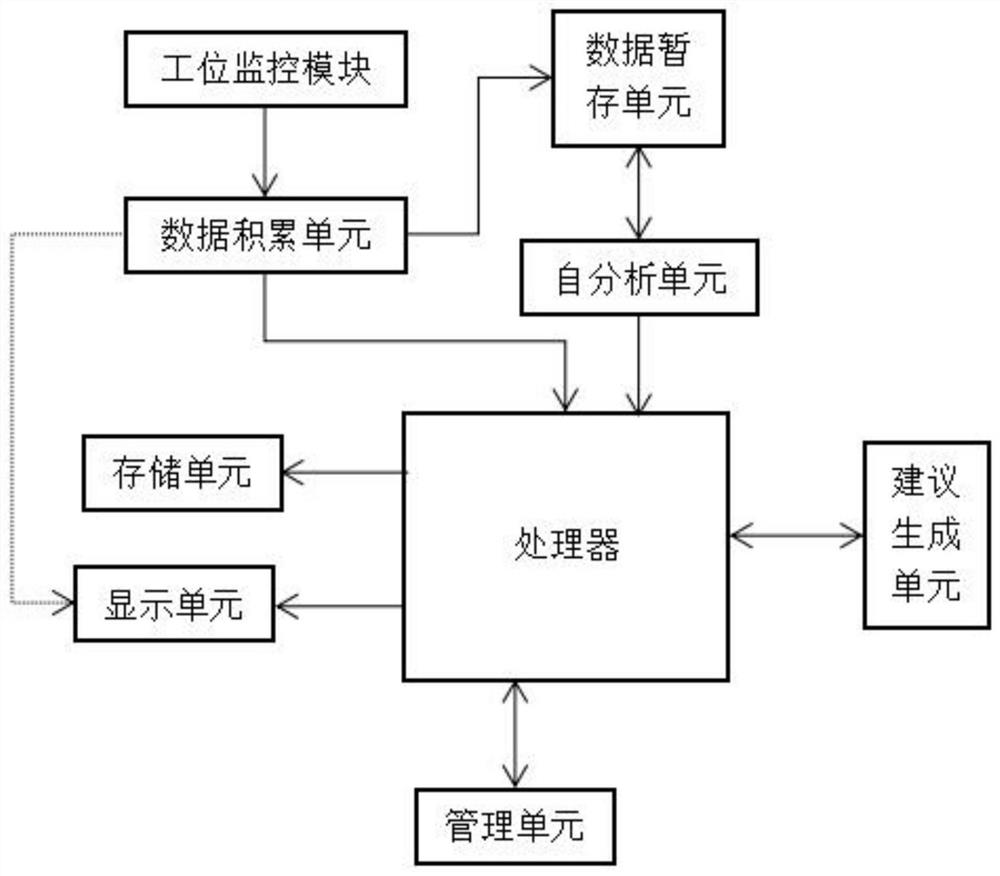

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

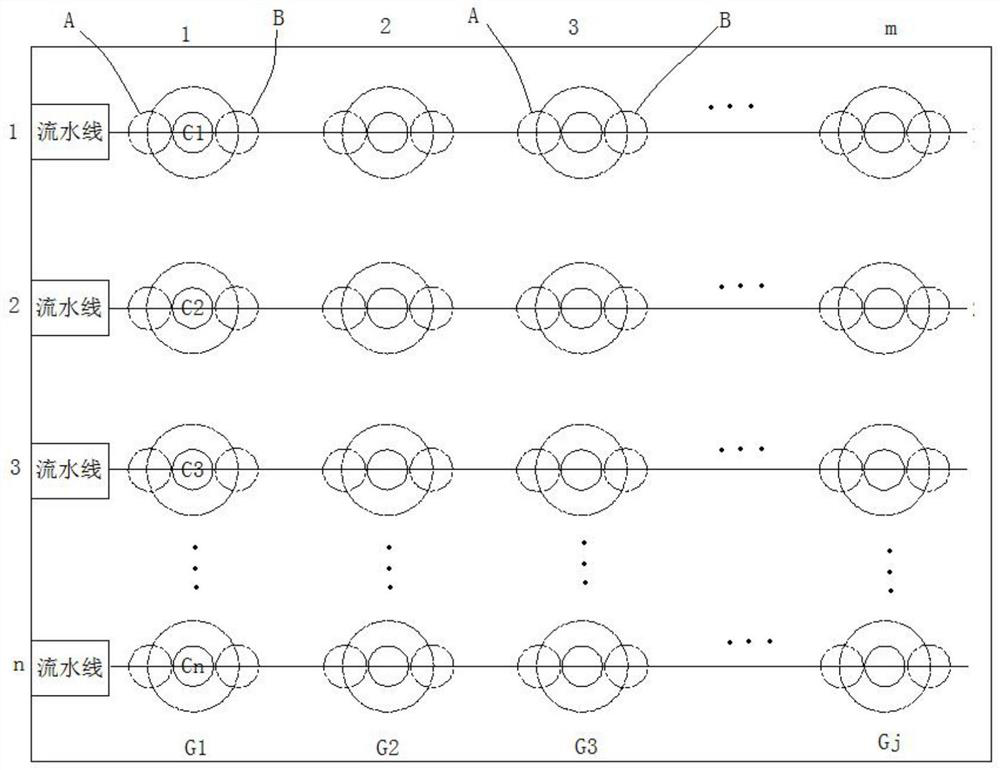

[0045] Such as figure 2As shown, to produce a certain equipment, n assembly lines are required, and each assembly line is equipped with m assembly and processing stations; The working hours Gj are specifically taken as follows:

[0046] Step 1: Obtain the first station, that is, the station at the first position of the n assembly lines, and obtain the time required for processing a single workpiece. The specific acquisition method is:

[0047] S1: Obtain the entry signal when the workpiece enters the first station and the departure signal when it leaves the first station through the station monitoring module;

[0048] S2: When the workpiece enters from the station, the timing starts when the entry signal is generated, and the timing stops when the workpiece leaves the station and the departure signal is generated. The time between the start of timing and the stop of timing is the processing time of a single workpiece;

[0049] S3: Acquire the processing time of a single wor...

Embodiment 2

[0055] The self-analysis unit is used for self-analysis and processing of the single man-hour group Gj of the data temporary storage unit, specifically:

[0056] SS1: Calculate the average value Pg of the single-piece man-hour group Gj,

[0057] SS2: After using the formula Calculate the stable value W;

[0058] SS3: Remove G1 to obtain a new single-piece man-hour group G g1 ;

[0059] SS4: Calculation of new unit hours group G g1 mean value of P g1 , And calculate the destabilization value W1,

[0060] SS5: Remove G2 to obtain a new unit-hour group G g2 , then repeat the principle of step SS4 to calculate the corresponding destabilizing value W2; remove G3~Gm in turn to obtain the destabilizing value group Wj composed of m destabilizing values, j=1, 2, 3, ..., m, m is a positive integer;

[0061] SS6: According to the analysis of destabilizing value Wj, stabilizing value W, unit working hours Gj, and average value Pg, cumbersome work stations are obtained; the ...

Embodiment 3

[0065] The way to obtain the entry signal and exit signal is:

[0066] Such as figure 2 As shown, the observation area is set at the specified distance before and after the station; specifically, as figure 2 As shown, the observation area A and the observation area B are set at the specified distance before and after the station C1, and the photos of the two observation areas are obtained through the station monitoring module, and are respectively marked as the front observation map T q and post-observation graph T h , after which the real-time photos of the front and rear observation areas are obtained every interval T1, and the obtained real-time photos are respectively compared with the corresponding front observation map T q and post-observation graph T h Compare and obtain the area of the difference;

[0067] Current and previous observation graph T q When the difference area exceeds the preset value, an entry signal is generated;

[0068] When and after observi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com