Washing machine and control method thereof

A control method and a washing machine technology, applied in the field of washing machines, can solve the problem of inability to heat washing water, and achieve the effects of avoiding excessive heating time, improving practical promotion, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

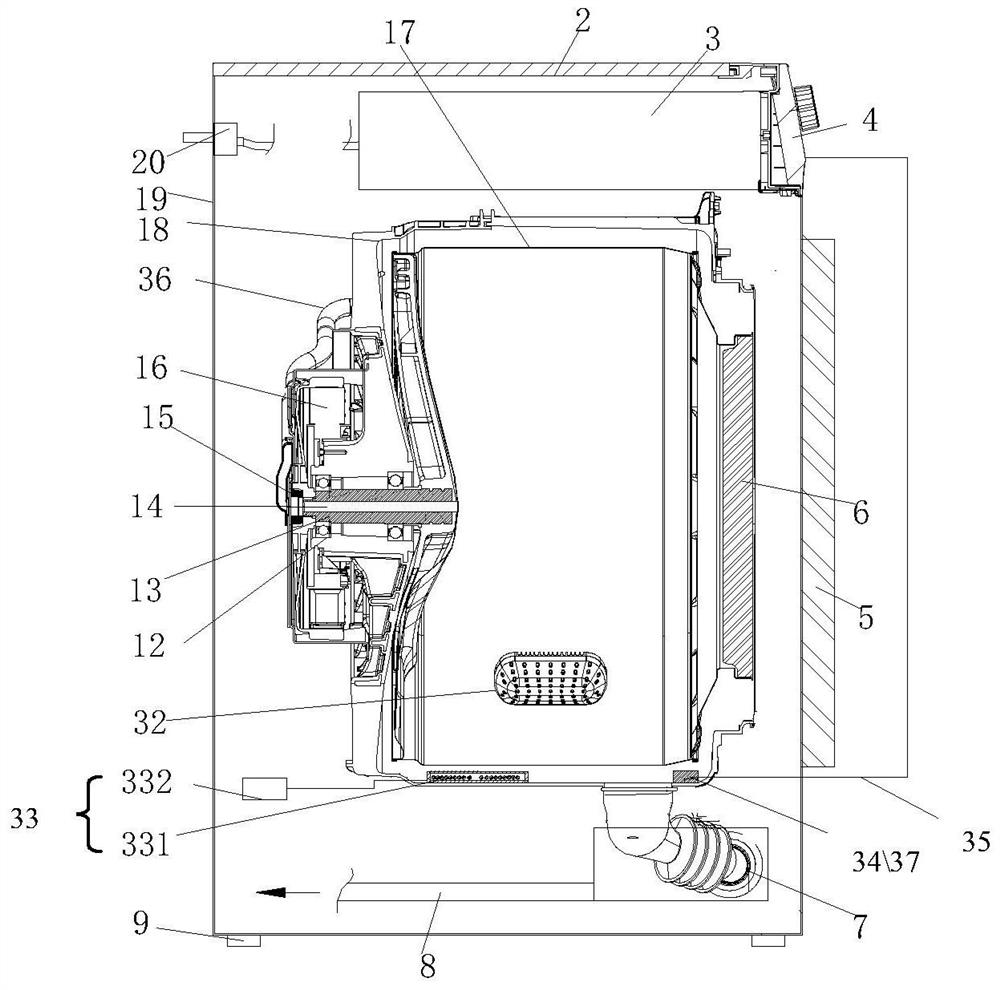

[0060] This embodiment mainly solves the problem that when the non-porous inner drum washing machine executes the heating program, the heating temperature cannot be well controlled, resulting in low water temperature, which affects the washing effect; or high water temperature, causing damage to the clothes.

[0061] combine figure 1 with figure 2 , the present embodiment provides a washing machine comprising: an inner cylinder 17, which holds washing water independently when washing clothes, avoiding the accumulation of dirt outside the inner cylinder 17 and the problems of over-flowing washing water and bacterial growth; an electromagnetic heating device 33, heating the inner cylinder 17, and then heating the washing water in the inner cylinder 17 to enhance the decontamination ability, and at the same time, the heated washing water can also sterilize and disinfect the clothes; the temperature detection device 34 directly detects the water temperature in the inner cylinder ...

Embodiment 2

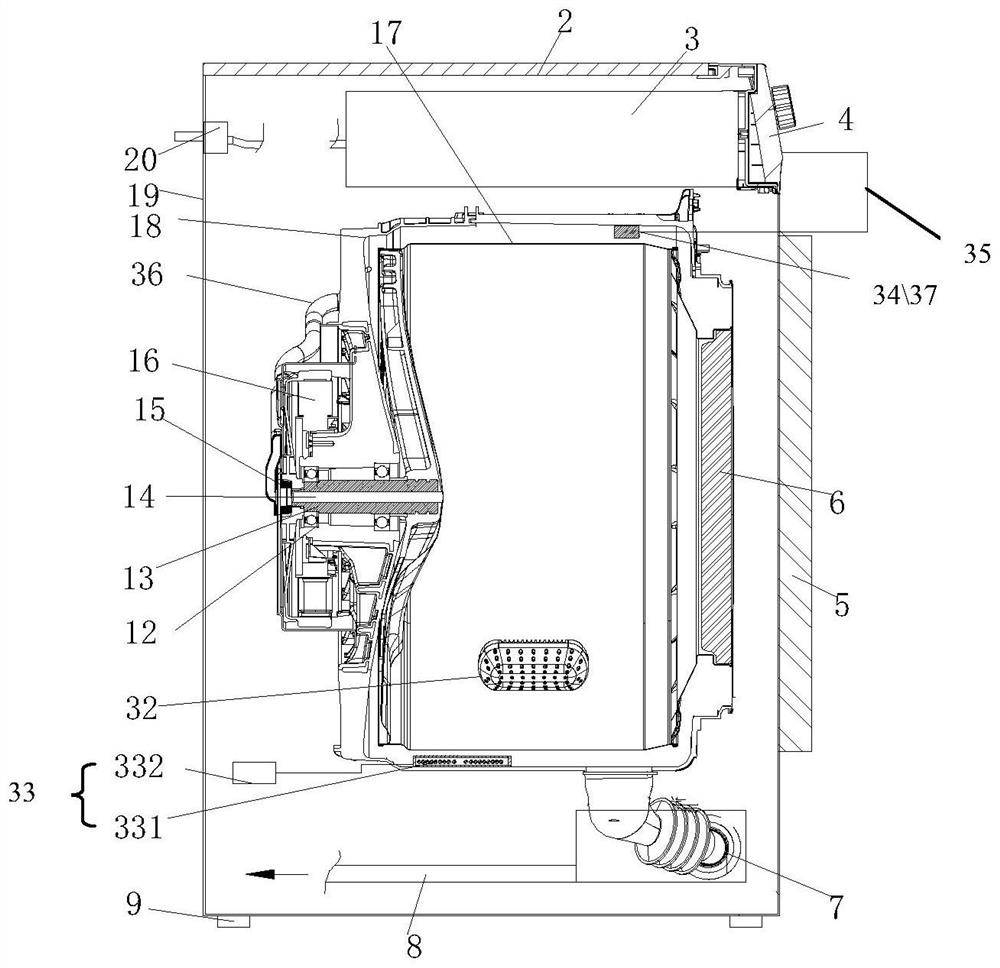

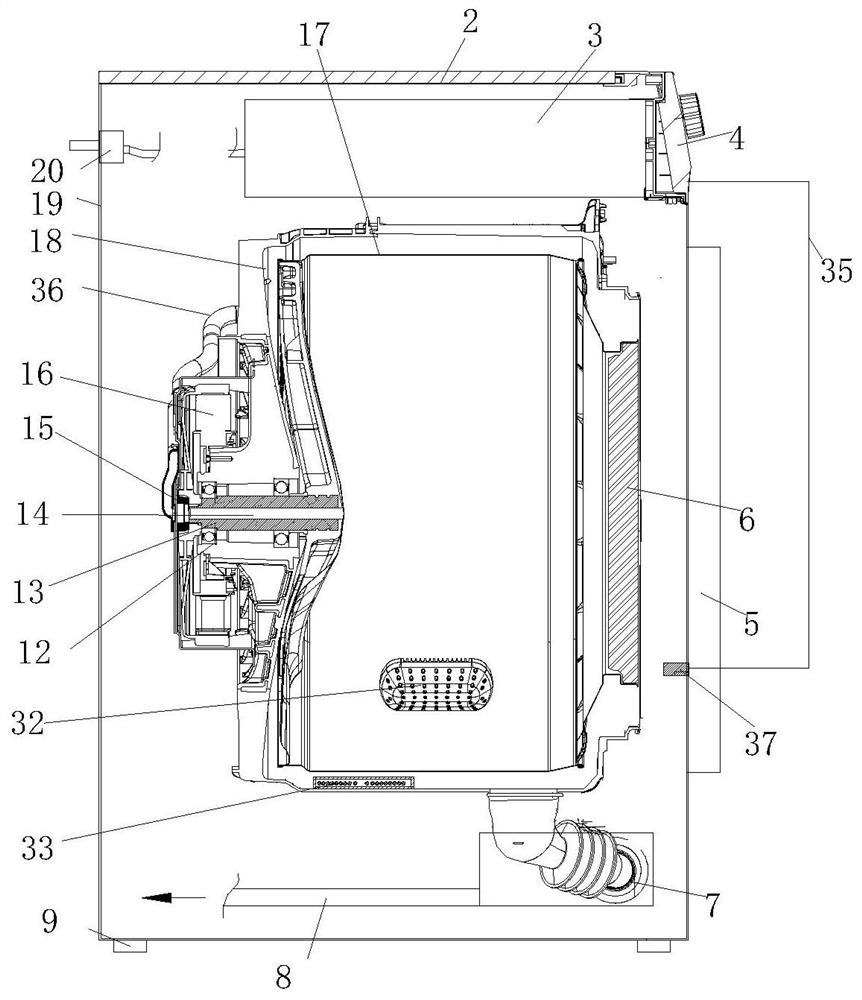

[0076] This embodiment is an improvement made on the basis of the first embodiment. A non-contact temperature detection device is used, and the temperature measurement result is more accurate.

[0077] combine figure 1 , figure 2 , image 3 , the present embodiment provides a washing machine, comprising: an inner cylinder 17, which holds washing water independently when washing clothes, avoiding the problems of accumulation of dirt and bacterial growth caused by accumulation outside the inner cylinder 17 and overflowing washing water; electromagnetic heating The device 33 heats the water in the inner cylinder 17 to enhance the decontamination ability, and the heated washing water can also sterilize the clothes; the non-contact temperature detection device 37 detects the water temperature in the inner cylinder 17, or detects the temperature of the inner cylinder 17. The temperature of the cylinder 17, the non-contact temperature detection device adopted in this embodiment ha...

Embodiment 3

[0093] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the temperature detection device used measures the initial water inlet temperature, and the control unit of the washing machine controls the operation of the heating device according to the current water inlet temperature and water inlet volume.

[0094] combine Figure 4 , the present embodiment provides a washing machine, comprising: an inner cylinder 17, which holds washing water independently when washing clothes; a water inlet system, the water inlet system communicates with the inner cylinder 17; a heating device 33, which heats the inner cylinder The water in the barrel 17; the temperature detection device (not shown in the figure), is arranged in the water inlet system to detect the inlet water temperature. The temperature of the water inlet can be detected in real time by the temperature detection device provided in the water inlet system, so as to ensure that the control system of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com