Mounting structure of telescopic contact pin temperature sensor

A technology of a temperature sensor and an installation structure, applied in the field of microwave ovens, can solve the problems of inability to detect, overcooked food and insufficient heating time, poor cooking performance, etc., and achieve the effects of ensuring cooking performance, small occupied space, and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

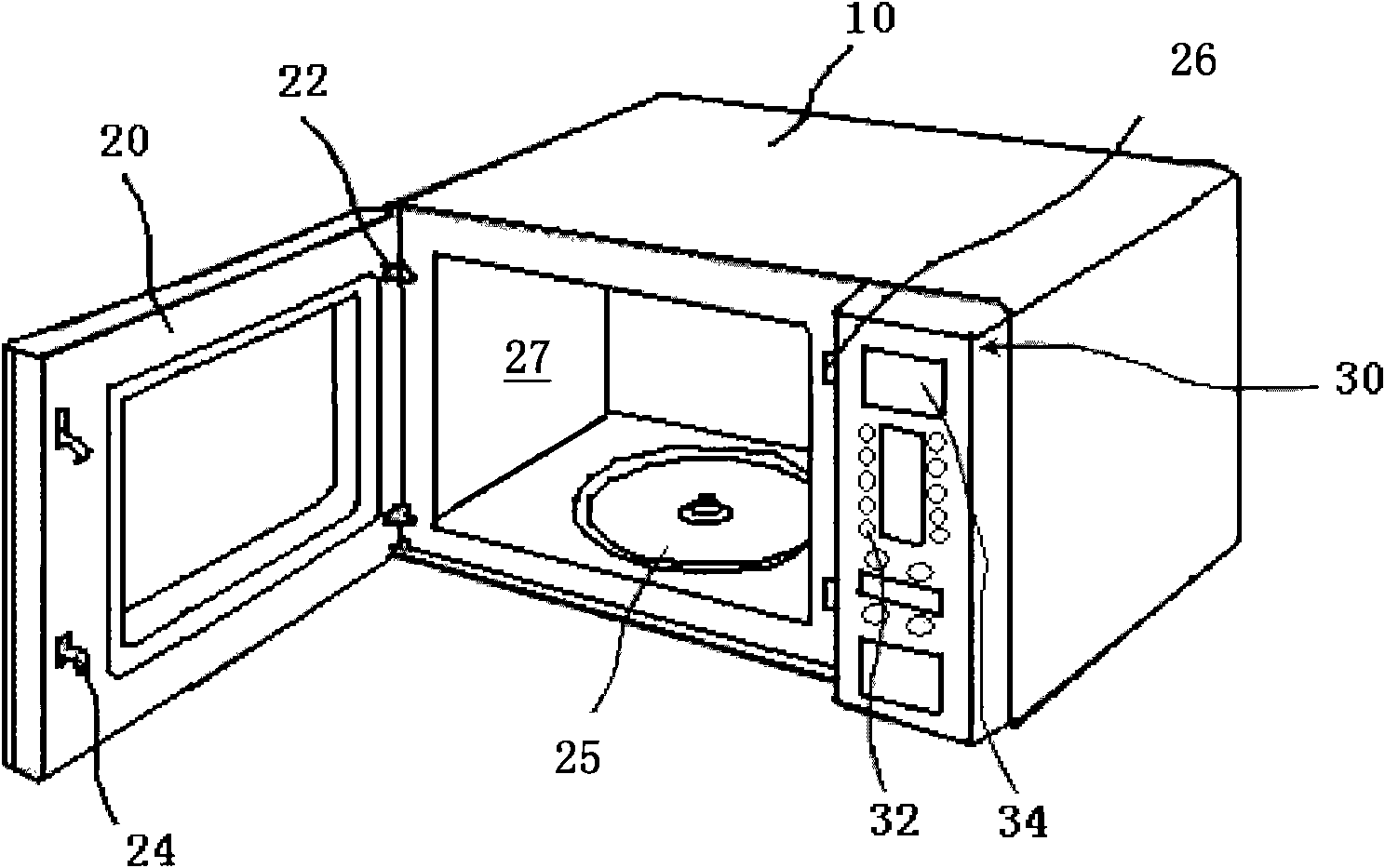

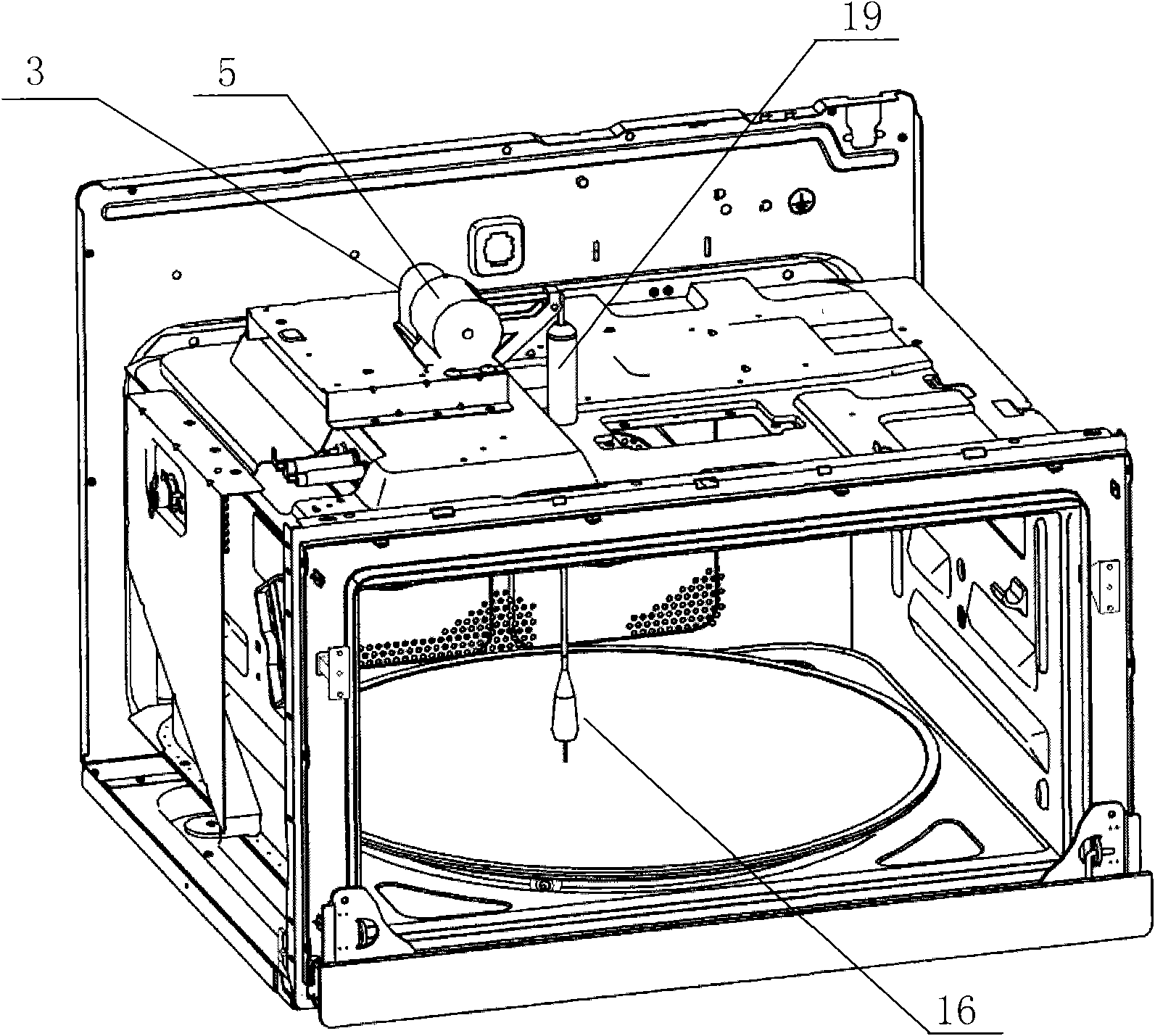

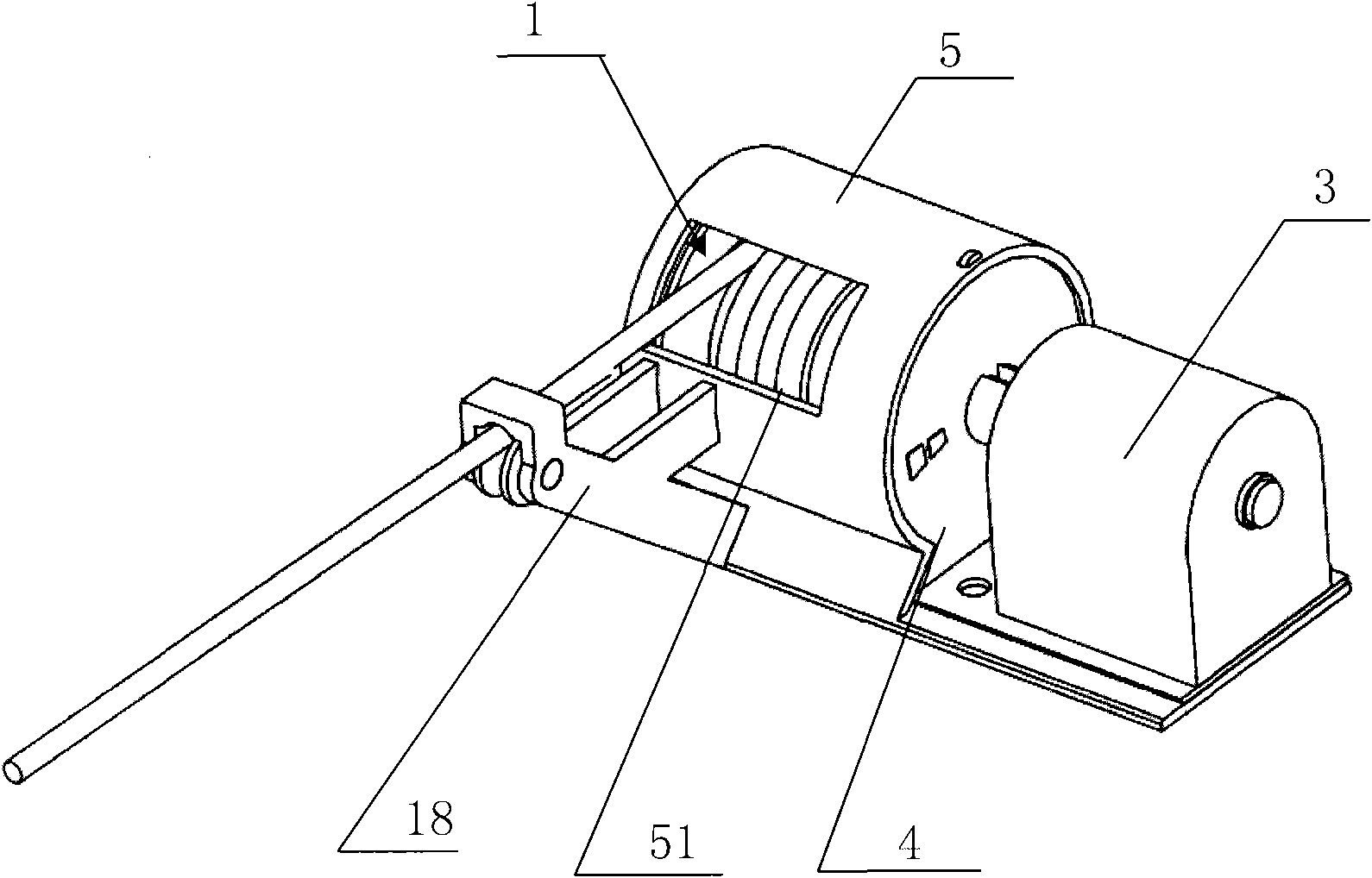

[0043] Hereinafter, the installation structure of the retractable pin temperature sensor for a microwave oven according to the present invention will be described in detail with reference to the drawings and embodiments.

[0044] Such as figure 2 , image 3 , Figure 4 As shown, the installation structure of the retractable pin temperature sensor for microwave ovens of the present invention includes a data acquisition unit 1, a data transmission unit 2, a drive unit 3 and a bracket for supporting the data transmission unit 2 and the drive unit 3 4.

[0045] in:

[0046] The data collection unit 1 is arranged on the outer surface of the top of the microwave oven cavity. The data collection end of the data collection unit 1 runs through the top of the microwave oven cavity and moves up and down into the microwave oven cavity for collecting food in the cavity. temperature, and the data output end is connected with the data transmission unit 2;

[0047] Such as image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com