Automatic dosing system and a circulating water cooling system

A technology of automatic dosing and dosing pumps, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of preventing damage, reducing labor intensity, and preventing proportional imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

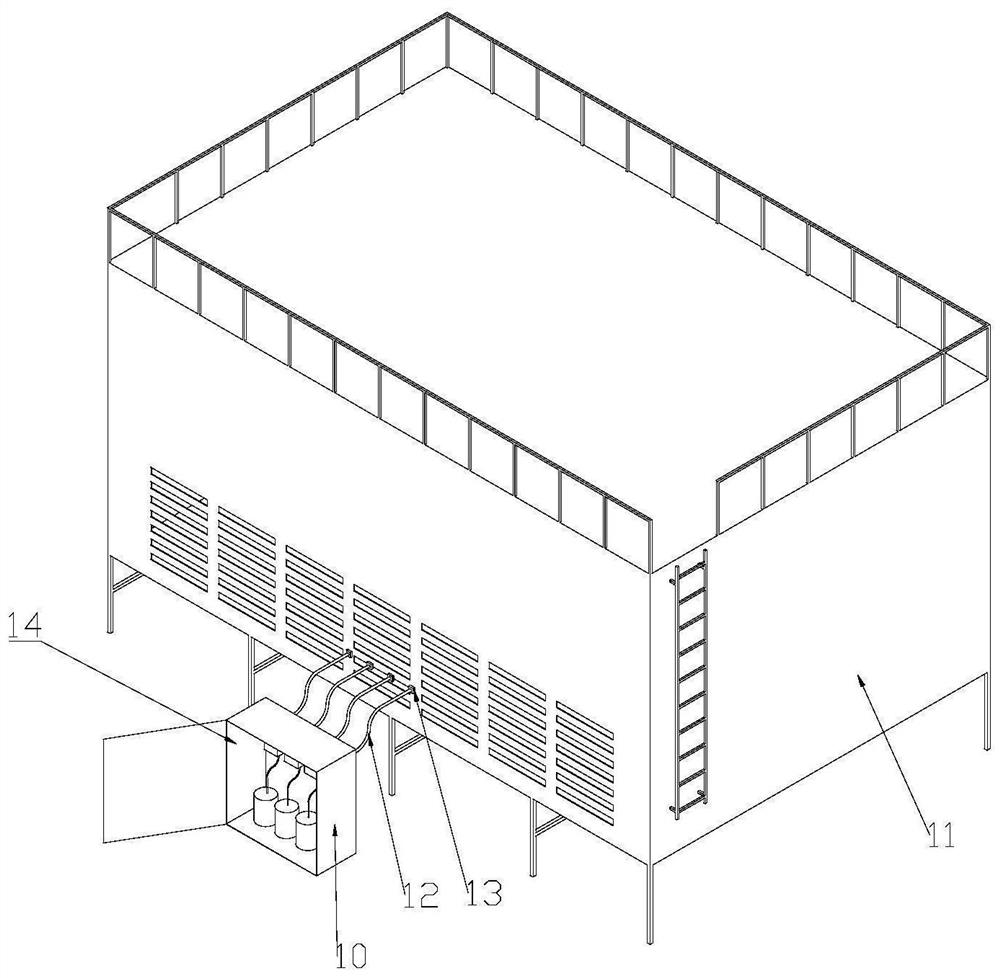

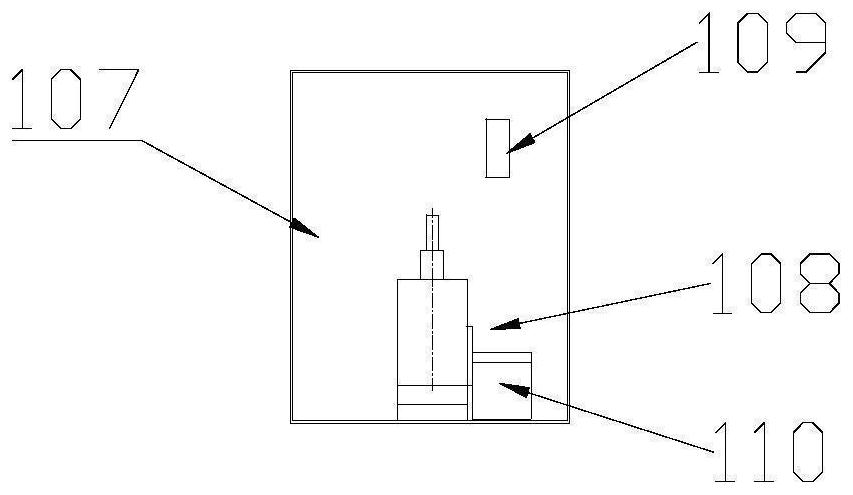

[0028] Present embodiment 1 provides a kind of automatic loading device of the present invention, as figure 1 As shown, an automatic dosing system provided by the present invention includes a dosing control mechanism 10 and a water tank 11 . Wherein, the dosing control mechanism 10 includes at least one automatic dosing component, and each automatic dosing component is connected to the water tank 11 through the first pipe 12, and each automatic dosing component can control a single medicine to be added to the water tank 11 in a regular and quantitative manner. Inside. By making each automatic dosing component control the timing and quantitative addition of a single medicine to the water tank, each medicine that needs to be added is added in a regular and quantitative manner, thereby realizing the process of automatically adding medicine to the water tank without manual dumping. It reduces the labor intensity and avoids the splashing and hurting people when pouring manually, a...

Embodiment 2

[0039] This embodiment 2 uses the automatic dosing system of embodiment 1 to set the timer in the automatic control mechanism for the four kinds of medicaments according to the optimal dosage of medicaments, and to test the water quality after the dosing treatment of the water in the water tank , the specific settings and test results are as follows:

[0040] In this embodiment, the ratio of the sterilizing algaecide to water in the first medicine storage tank 101 is 115kg of 3000T water. Set the timer for controlling the automatic dosing part of the bactericide and algicide, preset the continuous dosing time T1 as 5min, and the interval time T2 as 1h, so as to realize the automatic dosing frequency of the bactericide and algicide 1 per hour times, each continuous dosing for 5 minutes.

[0041] The proportioning ratio of the dispersion stripping agent and water in the second medicine storage tank 102 is 3000T water proportioning 115kg. The timer used to control the automatic...

Embodiment 3

[0050] This embodiment provides a circulating water cooling system, including the automatic dosing system described above. Therefore, applying the automatic dosing system of Embodiment 1 or Embodiment 2 to the circulating water cooling system can ensure the water quality of the cooling water tower of the circulating water cooling system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com