Light-weight semi-trailer self-discharging carriage based on modular assembly design

A lightweight and modular technology, applied in the arrangement of loading and unloading vehicles, vehicles used for freight, vehicles with inclined bearing motion, etc., can solve the problems of inability to form semi-finished product inventory, no semi-finished product inventory, single production method, etc. The effect of quantitative design, speeding up production takt, and reducing the weight of the carriage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

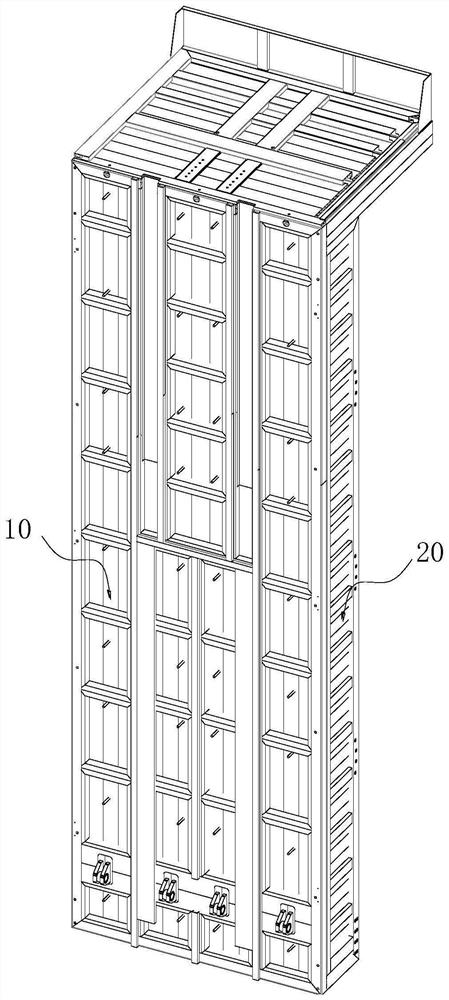

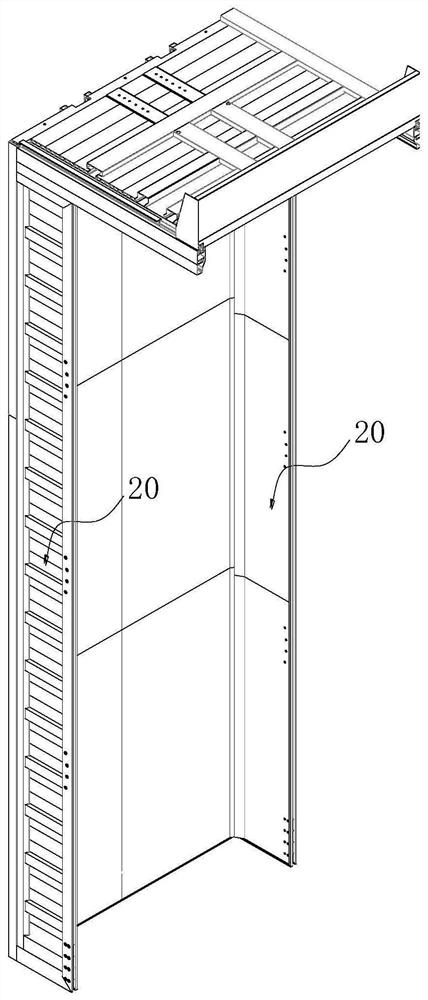

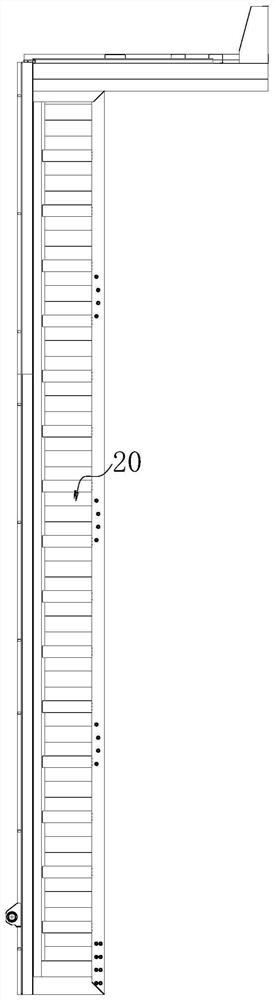

[0043] Such as Figure 1 to Figure 16 As shown, a lightweight semi-trailer dump car based on a modular assembly design includes a floor assembly 10 and a side panel assembly 20, and a convex edge 30 is formed extending upward on the peripheral side of the upper surface of the floor assembly 10. A first installation groove 40 is opened on the outer side of the convex edge 30, and a groove 50 adapted to the convex edge 30 is formed on the lower edge of the side plate assembly 20, and the groove 50 is A second installation groove 60 is opened on the side wall, and the setting position of the second installation groove 60 is adapted to the first installation groove 40, and the first installation groove 40 and the second installation groove 60 form an accommodating cavity, A clamping strip 70 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com