Detecting mechanism for presence or absence of feeding running water of drawing part

A detection mechanism and flow technology, applied in measuring/indicating equipment, metal processing machinery parts, clamping, etc., can solve the problems of poor cutting quality, inconvenient use, and inability to judge whether steel wool is incoming or not. , to achieve a high degree of automation, easy to use, good handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

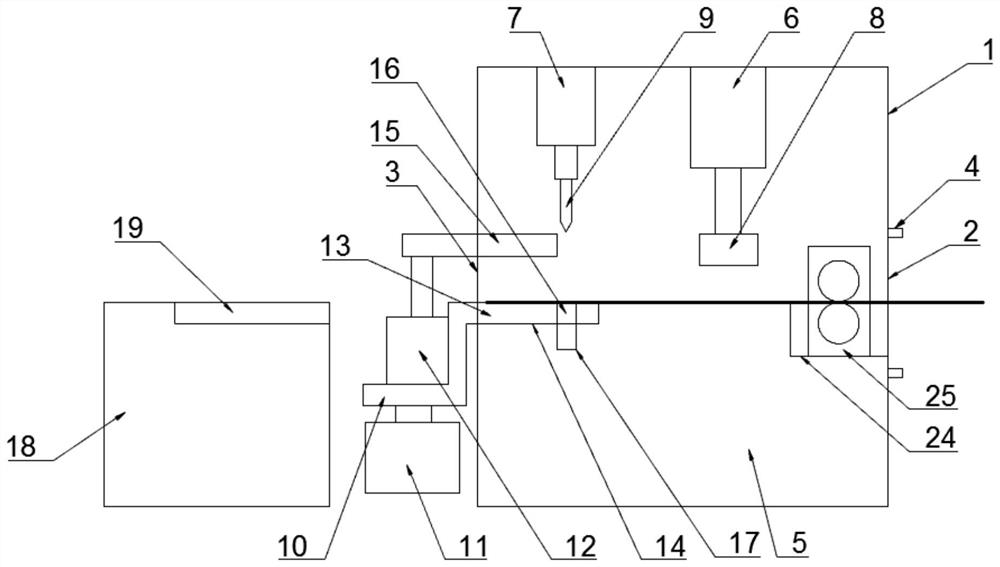

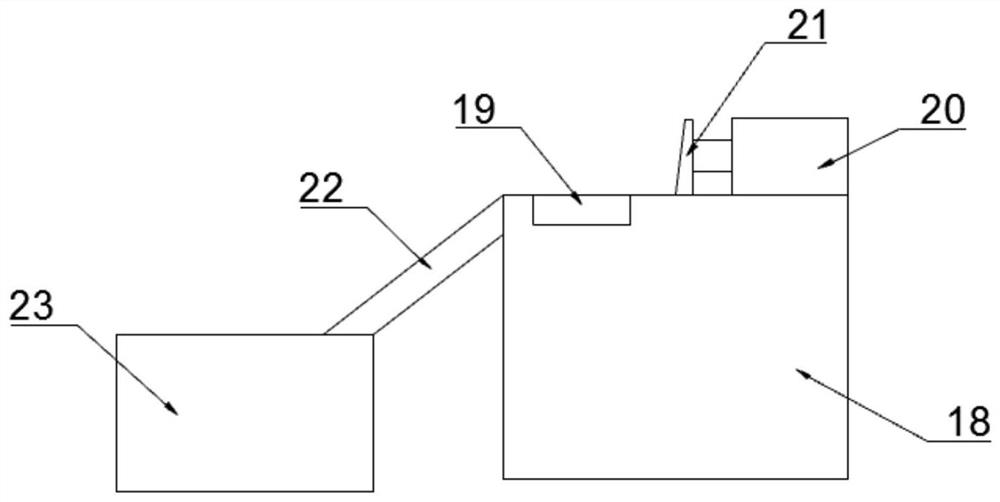

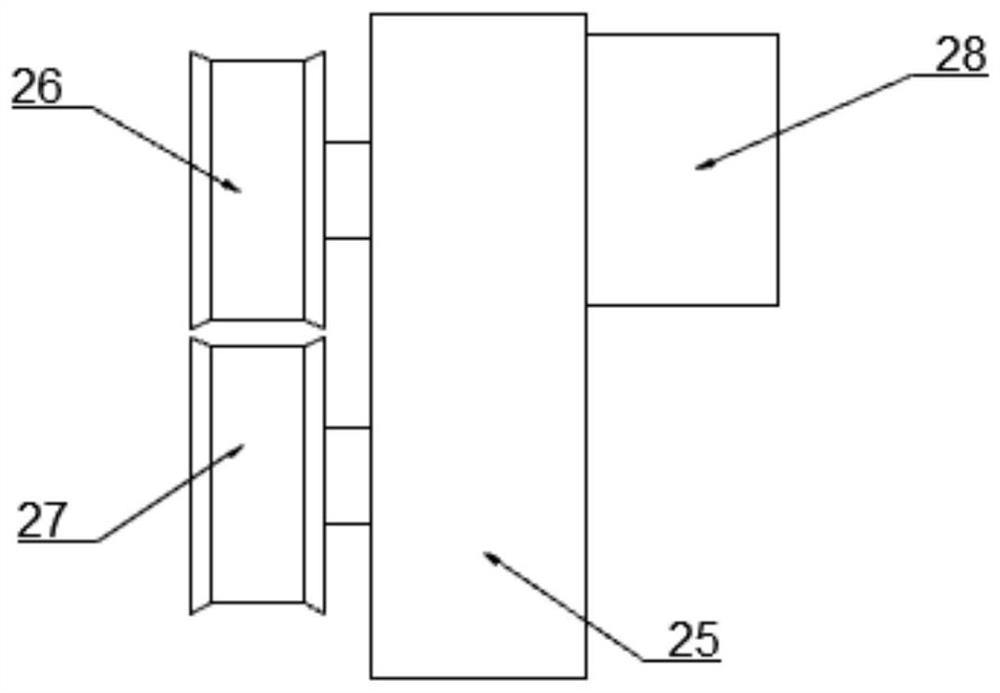

[0018] Such as Figure 1 to Figure 3 As shown, a detection mechanism for the presence or absence of flowing water incoming materials for stretching parts includes a protective cover 1, and the two sides of the protective cover 1 are respectively provided with a feed port 2 and a discharge port 3, and the protective cover 1 at the feed port 2 is A through-beam photoelectric sensor 4 is installed, and the through-beam photoelectric sensor 4 includes a transmitter and a receiver, and the transmitter and the receiver are respectively located above and below the feed port 2 . The protective cover 1 is provided with a workbench 5, and the workbench 5 is provided with a feeding device near the feeding port 2, and the workbench 5 is provided with a third groove 24, and the feeding device is located at the third groove 24, and the feeding device Including mounting plate 25, driving wheel 26 and driven wheel 17, driving wheel 26 and driven wheel 17 are installed on the mounting plate 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com