High-horsepower engine gear chamber cover and outer frame assembly

A gear chamber cover and engine technology, applied in the direction of engine components, machines/engines, shells, etc., can solve the problems of high-strength combined brackets for exhaust systems, etc., and achieve scientific and reasonable overall structure layout, light weight, and good rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

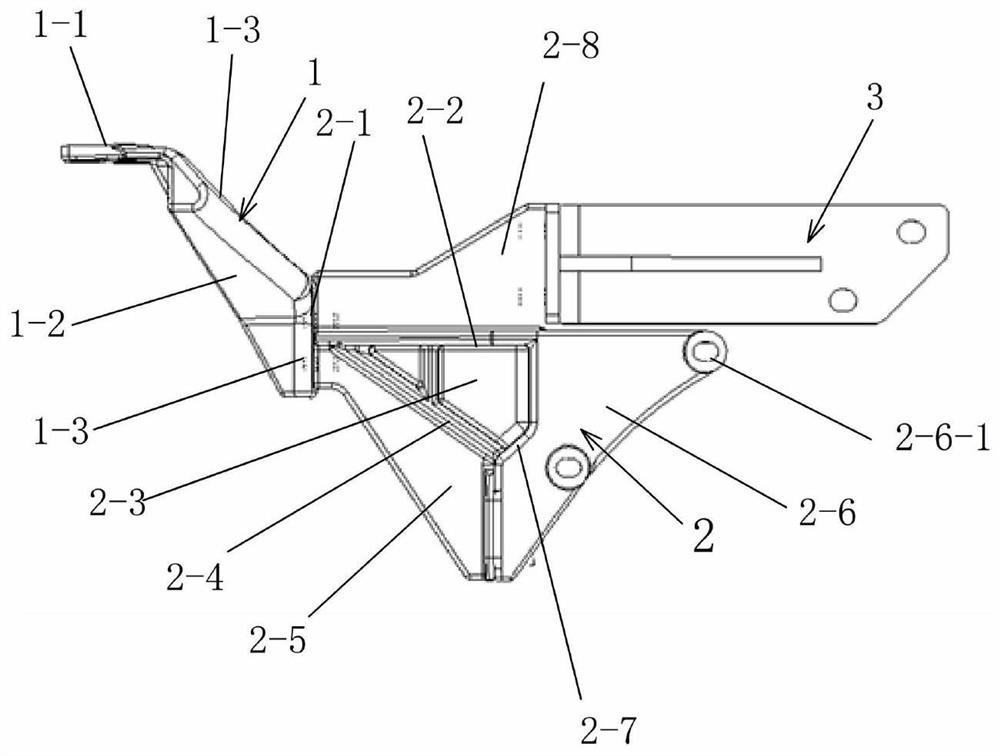

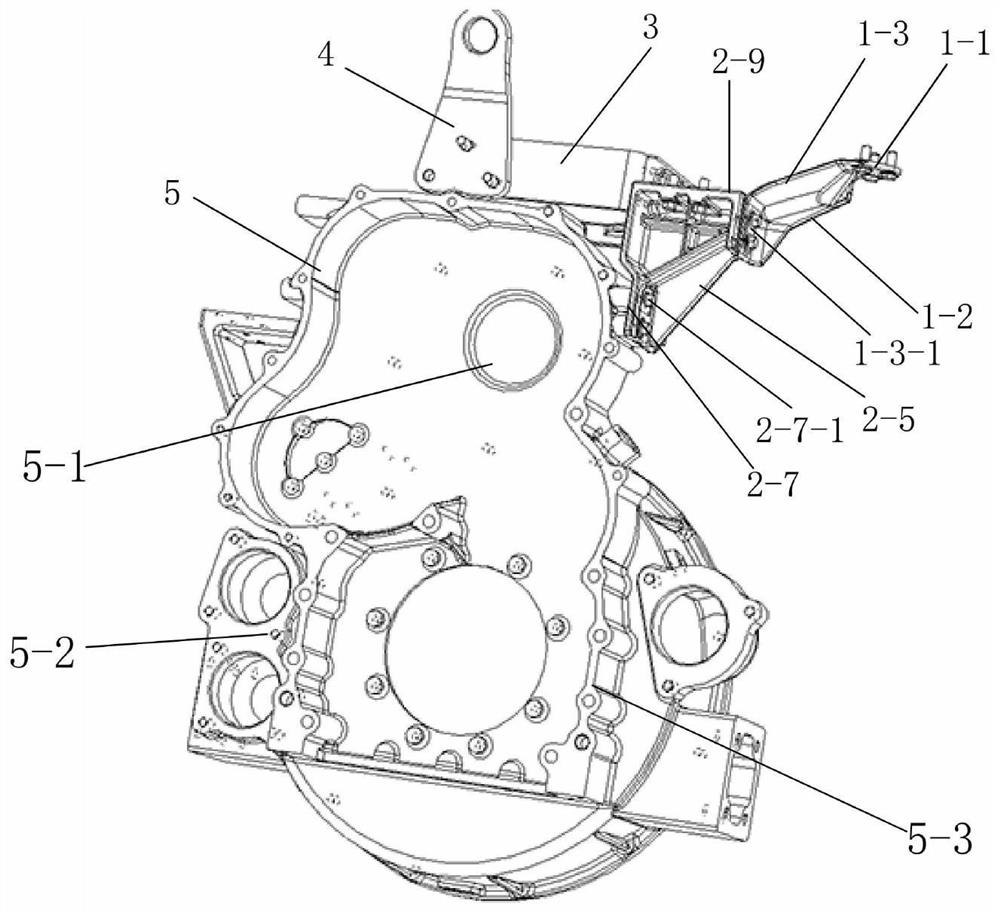

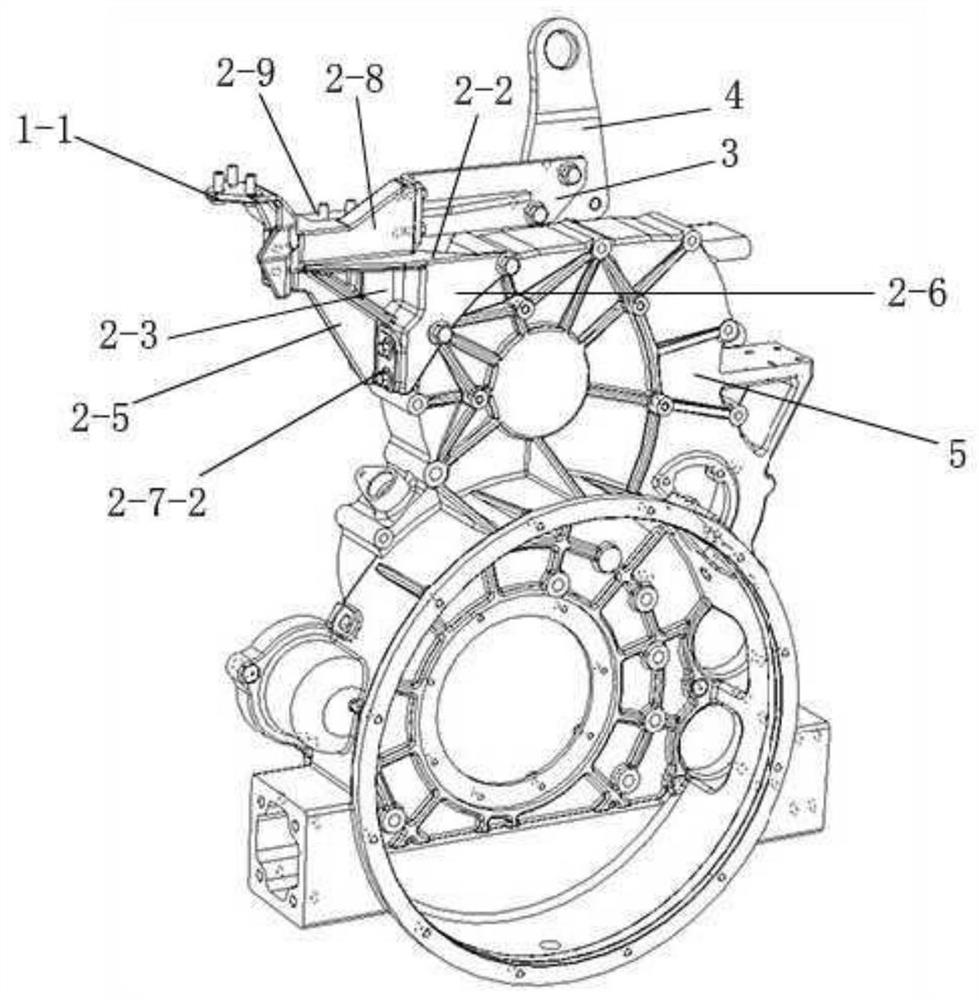

[0030] Such as Figure 1-6As shown, a high-horsepower engine gear chamber cover and outer frame assembly includes a combined bracket and a high-strength gear chamber cover; the lower part of the high-strength gear chamber cover 5 is provided with a flywheel housing; the high-strength gear chamber cover 5 The left side of the upper half chamber of the upper half chamber is designed to be recessed toward the middle relative to the left side of the lower half chamber; There are firm and tightened support ribs 5-3; the combined bracket is combined with the upper left of the upper half chamber; the combined bracket includes a turbine rear exhaust pipe bracket 1, a rear exhaust pipe main bracket 2 and a tension balance connecting bracket 3 ; The main bracket of the rear exhaust pipe includes a nearly "Y" shaped frame composed of the vertical support plate 2-7 and the left support plate 2-4 (the middle hollow part of the present embodiment is also provided with reinforcing ribs to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com