Improved electric barring gear of marine main engine

A technology of ship main engine and electric crank, which is applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of manual installation of crank crank, multi-manual assistance, etc., to avoid jamming and ensure the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

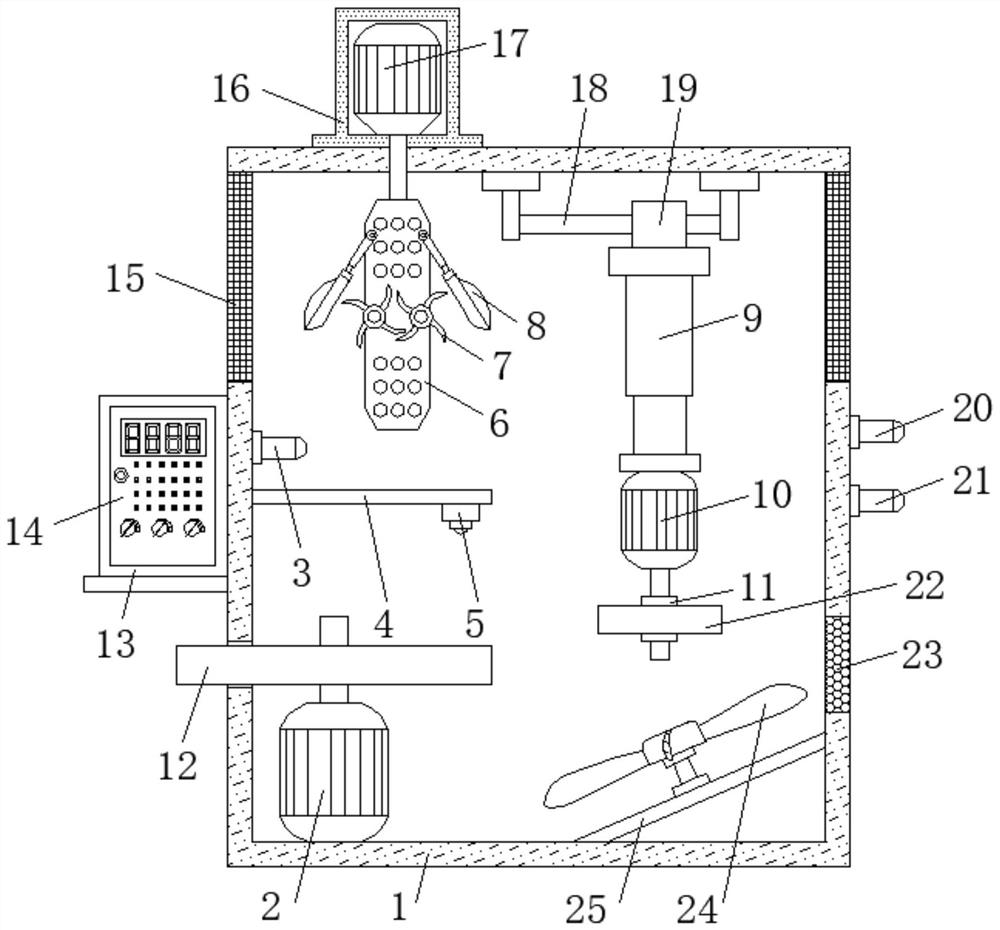

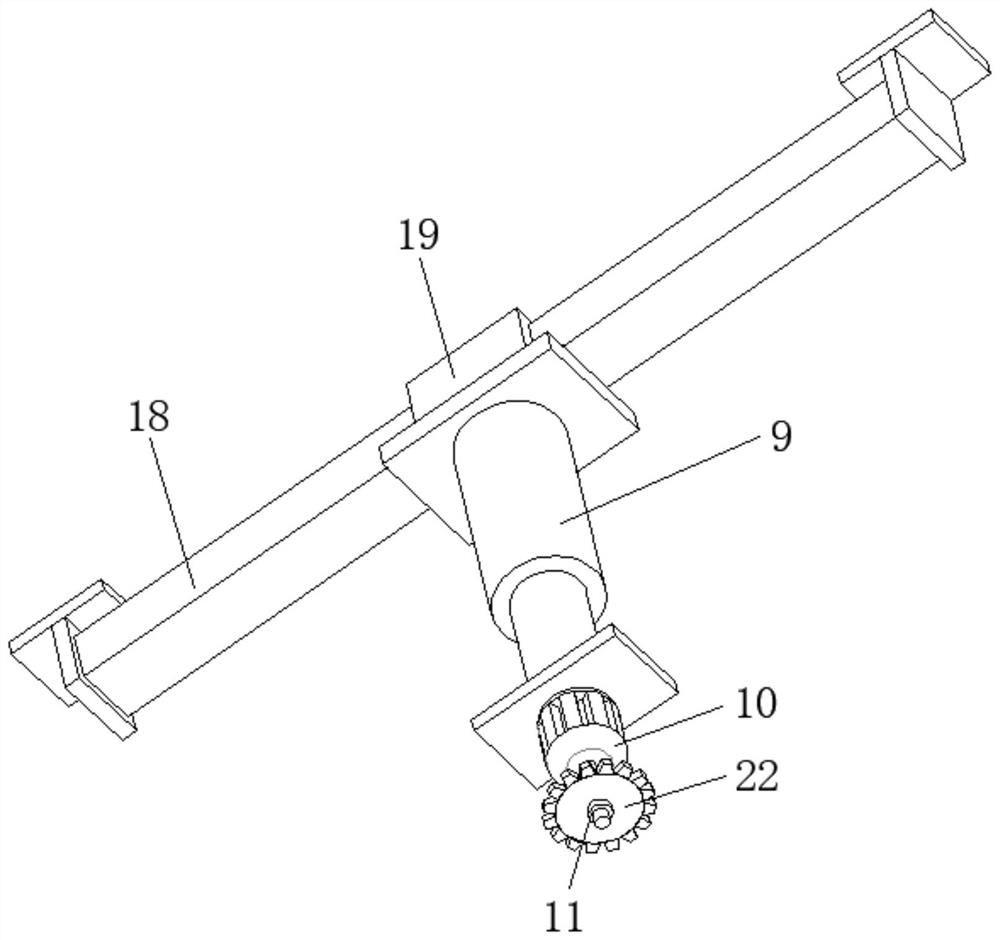

[0025] refer to Figure 1-2 , an improved ship main engine electric turning machine, including a box body 1 and a main motor 2, the main motor 2 is fixed on one side of the bottom inner wall of the box body 1 by bolts, and one end of the output shaft of the main motor 2 is sleeved with a driving wheel 12 One end of the driving wheel 12 is located outside the box body 1, and one side of the outer wall of the top of the box body 1 is fixed with an electric slide rail 18 by bolts, and a slider 19 is slidably connected to the outer wall of one side of the electric slide rail 18. An electric telescopic rod 9 is fixed on the outer wall of the bottom by a bolt, and one end of the extension rod of the electric telescopic rod 9 is fixed with a first motor 10 by a bolt. Both sides of the gear 22 are sleeved with the limit ring 11, and the position of the inner wall on one side of the box body 1 close to the driving wheel 12 is fixed with a horizontal plate 4 by bolts. The horizontal pla...

Embodiment 2

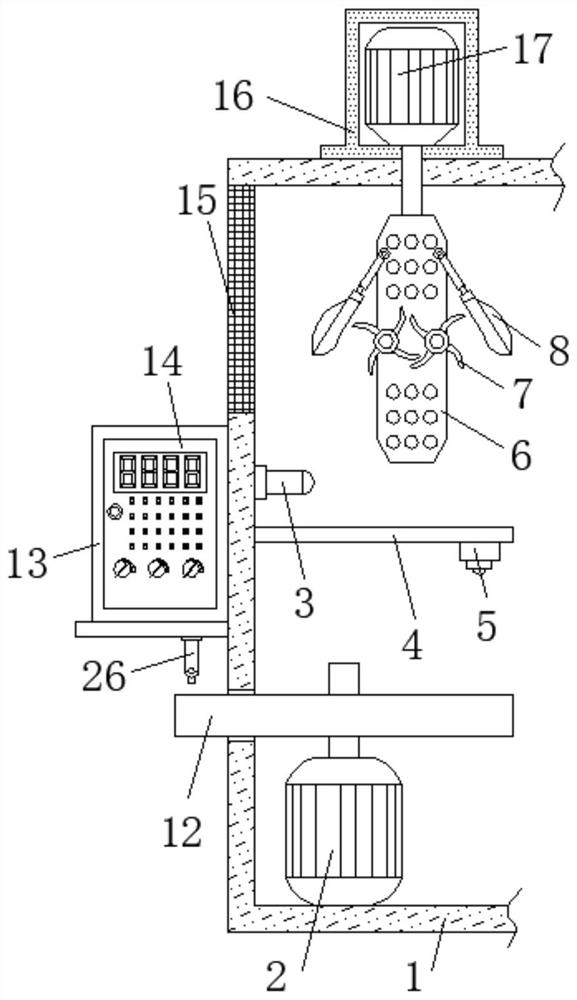

[0029] refer to image 3 , an improved ship main engine electric barring machine. Compared with Embodiment 1, this embodiment also includes a lubricant drop bottle 26, which is fixed by bolts on the outer wall of the bottom of the connecting plate near the position of the driving wheel 12.

[0030] During use, the lubricant dropping bottle 26 is located above the driving wheel 12, and the lubricant is dripped regularly, which can lubricate the gear position of the driving wheel 12, so that the driving wheel 12 can rotate more conveniently, and there will be no abnormal rotation, so that the jamming can be reduced. Dead situation occurs, guarantee that driving wheel 12 can work normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com