Determination method of the whole process horizontal bearing capacity of the device for improving the stability of brick columns in ancient buildings

A technology of horizontal bearing capacity and determination method, applied in construction, building maintenance, building construction, etc., can solve the problem of only focusing on the safety of the elastic stage, unable to meet the safety requirements of ancient buildings, unable to fully reveal the mechanical characteristics of ancient buildings, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

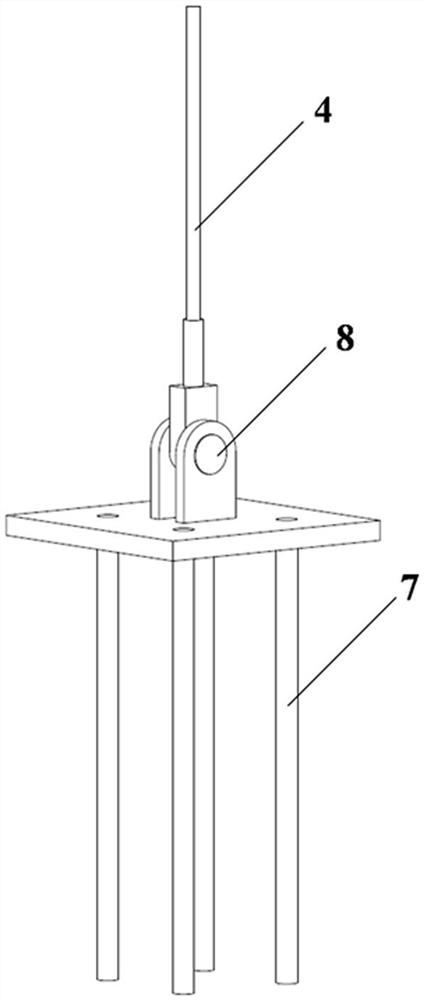

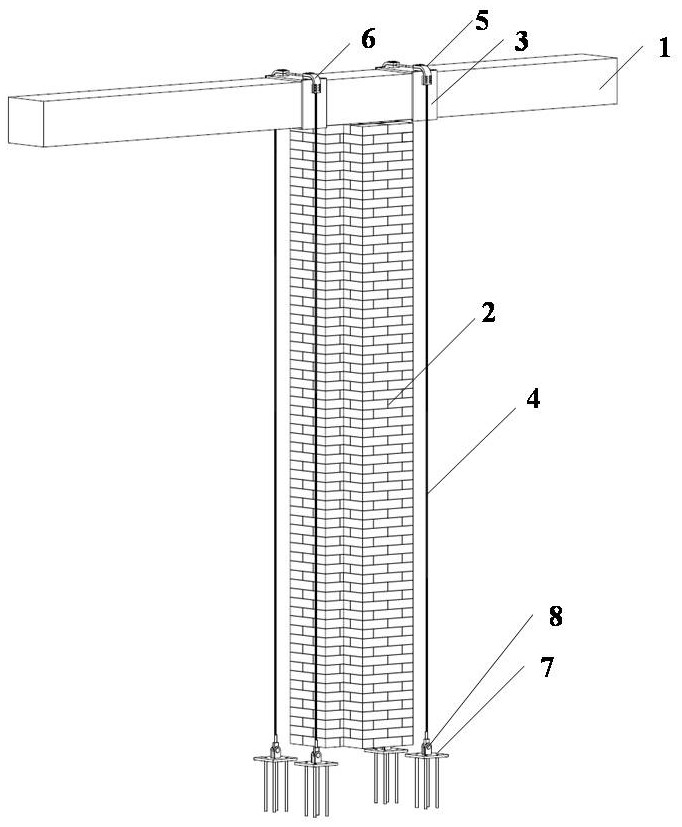

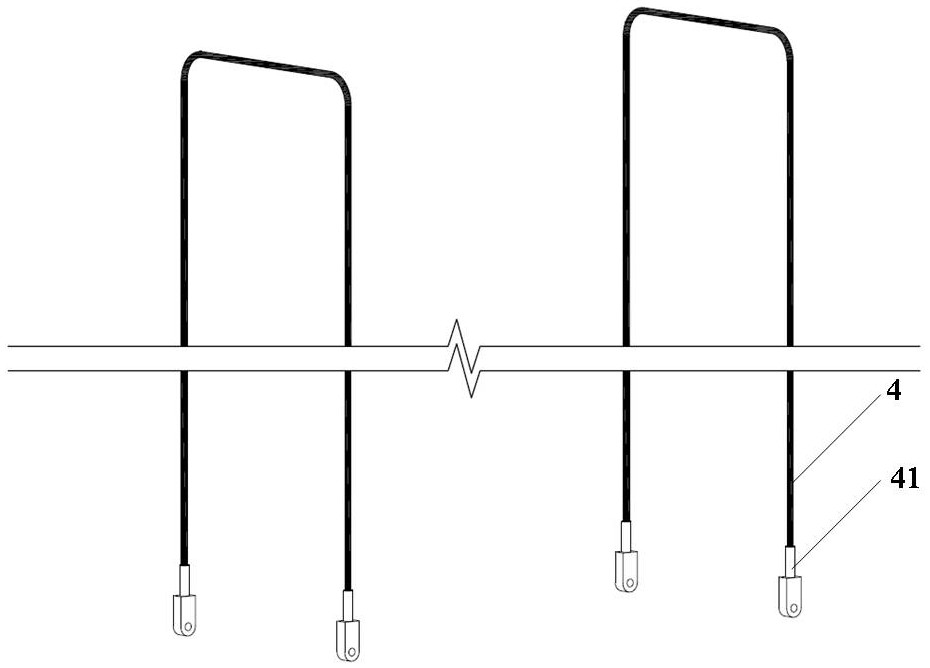

[0060] The embodiment of the method for determining the whole process horizontal bearing capacity of the safety and stability performance device of the ancient building brick column of the present invention comprises the following steps:

[0061] Step S1. Select an ancient building brick column and upper wooden roof truss structure, such as Figure 7 shown. Obtain the elastic modulus E of the block by using the rebound tester 1 =20000MPa, compressive strength fk 1 =5MPa, γ 1 =18KN / m 3 , the elastic modulus E of the masonry mortar is obtained by using the mortar penetrometer 2 =6000MPa, compressive strength fk 2 =1.2MPa, γ 2 =16KN / m 3 , use the same kind of blocks and mortar or mortar materials to masonry and carry out mechanical experiments, the friction coefficient μ between the blocks and the masonry mortar 1 =0.7 and the bond strength c=0.5 MPa. The material steel plate used to obtain the safety and stability performance of the ancient building brick column through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com