Building glass curtain wall roof

A glass curtain wall and architectural glass technology, applied in construction, building components, building maintenance, etc., can solve the problems of short service life, water leakage at joints, time-consuming and labor-intensive, etc., to slow down aging, prevent erosion, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

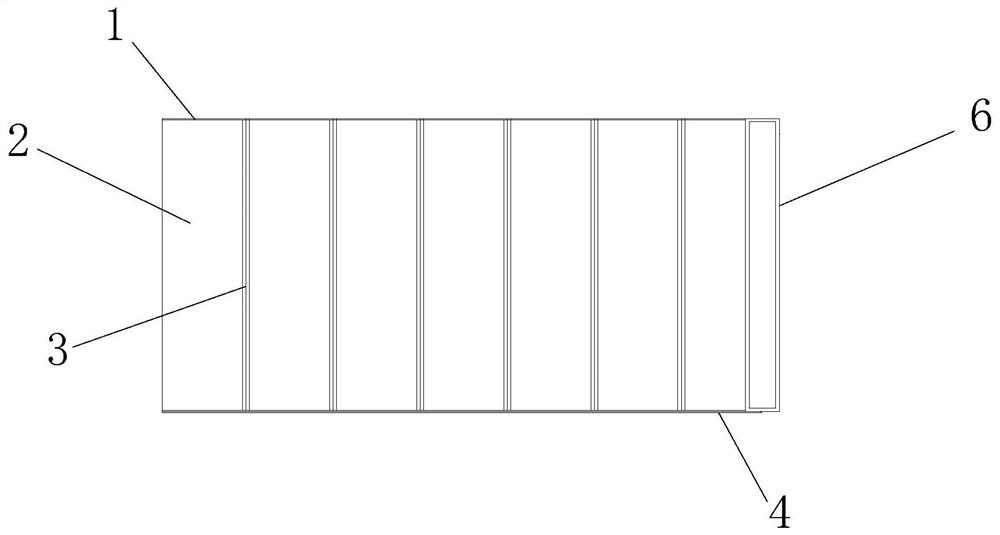

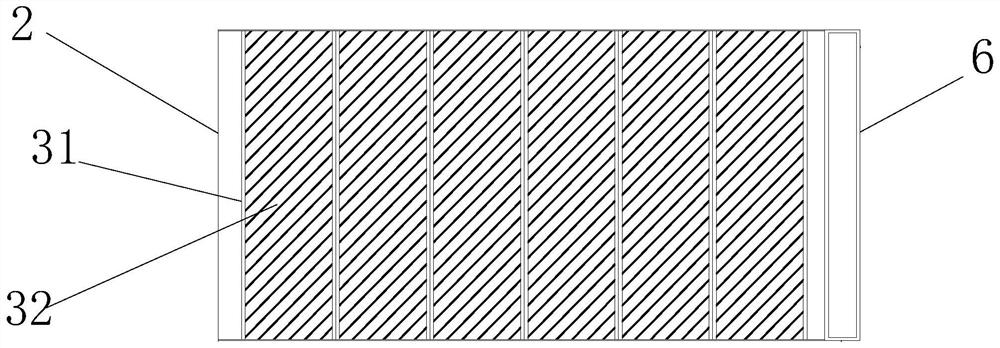

[0021] Such as figure 1 As shown, the glass curtain wall roof of this building includes a glass curtain wall roof composed of more than one glass curtain wall panel 2 spliced together. Glass glue is applied between adjacent glass curtain wall panels 2 to form a splicing seam, which is located on one side of the glass curtain wall roof. A water collection box 6 is set, and a floating sealing plate 62 is installed in the water collecting box 6. The upper end of the floating sealing plate 62 forms a water inlet chamber 61, and the bottom of the floating sealing plate 62 forms a sealed air storage chamber 63. An exhaust main pipe 4 is arranged at the bottom of the water box 6;

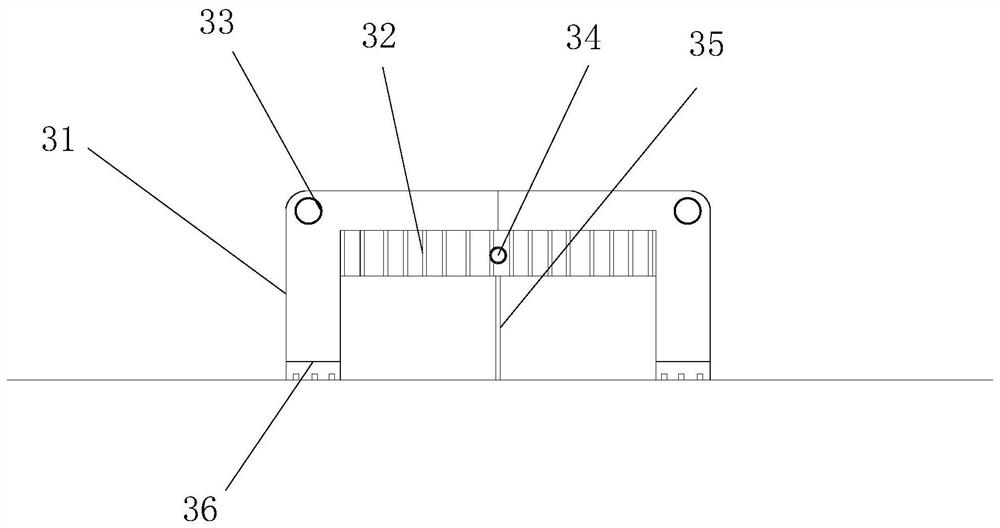

[0022] The upper end of each splicing joint is all slidably provided with a sealing protection strip 3, and more than one exhaust branch pipe 41 is set on the exhaust main pipe 4, and the exhaust branch pipe 41 is connected and conducted with the sealing protection strip 3. The sides are respectively sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com