Preparation method of high-purity menthol

A menthol, high-purity technology, applied in the field of high-purity menthol preparation, can solve the problems of low yield, inability to maintain natural characteristics, unfriendly environment, etc., and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] General embodiment: a kind of high-purity menthol preparation method comprises following preparation steps:

[0042] (1) Put mint crude oil at 40-50°C for 24-30h, and remove bottom moisture and impurities;

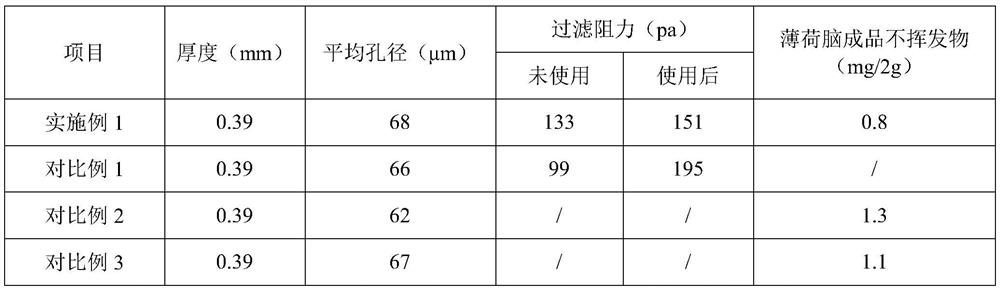

[0043] (2) Mix peppermint crude oil and ice oil at a mass ratio of 2:0.5-1, freeze out at -4~-10°C for 21-27 hours once, drain the oil to obtain primary oil and secondary oil, and then process the primary oil Heating to 55-60°C for melting, vacuum dehydration, and filtering through glass fiber filter paper to obtain naphtha;

[0044] (3) Mix Erbum oil and ice oil at a mass ratio of 1:1-1.5, freeze and freeze for a second time at -20 to -25°C for 50-60 hours, and drain the oil to obtain Erbum oil and hair oil; Heating the part of the brain to 55-60°C for heating and melting, vacuum dehydration, and filtering through glass fiber filter paper to obtain the dipepone oil;

[0045] (4) Mix 20-22 parts of virgin naphtha and 9-11 parts of digoxin, and add 8-9 parts of bak...

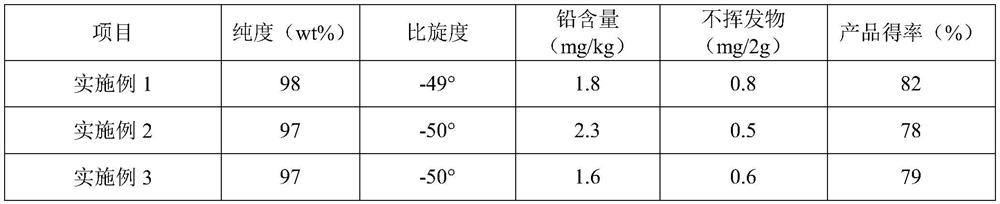

Embodiment 1

[0061] Embodiment 1: a kind of high-purity menthol preparation method comprises the following preparation steps:

[0062] (1) Put mint crude oil at 48° C. for 27 hours, and remove moisture and impurities at the bottom;

[0063] (2) Mix mint crude oil and ice oil at a mass ratio of 2:0.8, freeze out at -8°C for 25 hours once, drain the oil to obtain primary oil and secondary oil, then heat the primary oil to 58°C to melt and vacuum Dehydration, and filter through glass fiber filter paper, obtain early naphtha;

[0064] (3) Mix Erbum oil and ice oil at a mass ratio of 1:1.3, freeze out for 58 hours at -23°C for the second time, and drain the oil to obtain Erbum oil and hair oil; then heat Dimbum to 57°C for Heating and melting, vacuum dehydration, and filtering through glass fiber filter paper to obtain dipephalin;

[0065] (4) Mix 21 parts of naphtha and 10 parts of two parts of naphtha, add 8 parts of baked naphtha and 2 parts of melted oil, mix well at 57°C, and then carry ...

Embodiment 2

[0080] Embodiment 2: a kind of high-purity menthol preparation method comprises the following preparation steps:

[0081] (1) Place mint crude oil at 40°C for 30 hours, and remove bottom moisture and impurities;

[0082] (2) Mix mint crude oil and ice oil at a mass ratio of 2:0.5, freeze and freeze at -4°C for 21 hours once, and drain the oil to obtain primary and secondary oils, then heat the primary oil to 55°C to melt and vacuum Dehydration, and filter through glass fiber filter paper, obtain early naphtha;

[0083] (3) Mix Erbum oil and ice oil at a mass ratio of 1:1, freeze out for a second time at -20°C for 60 hours, and drain the oil to obtain Erbum oil and hair oil; then heat Dimbum to 55°C for Heating and melting, vacuum dehydration, and filtering through glass fiber filter paper to obtain dipephalin;

[0084] (4) Mix 20 parts of primary naphtha and 9 parts of digoxin, add 8 parts of roasted naphtha and 1 part of molten oil, mix well at 55°C, and then carry out cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com