Automatic thin plate bending equipment for industrial production

An automatic and equipment technology, applied in the direction of metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of cutting off unnecessary thin plates and automatic bending of thin plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

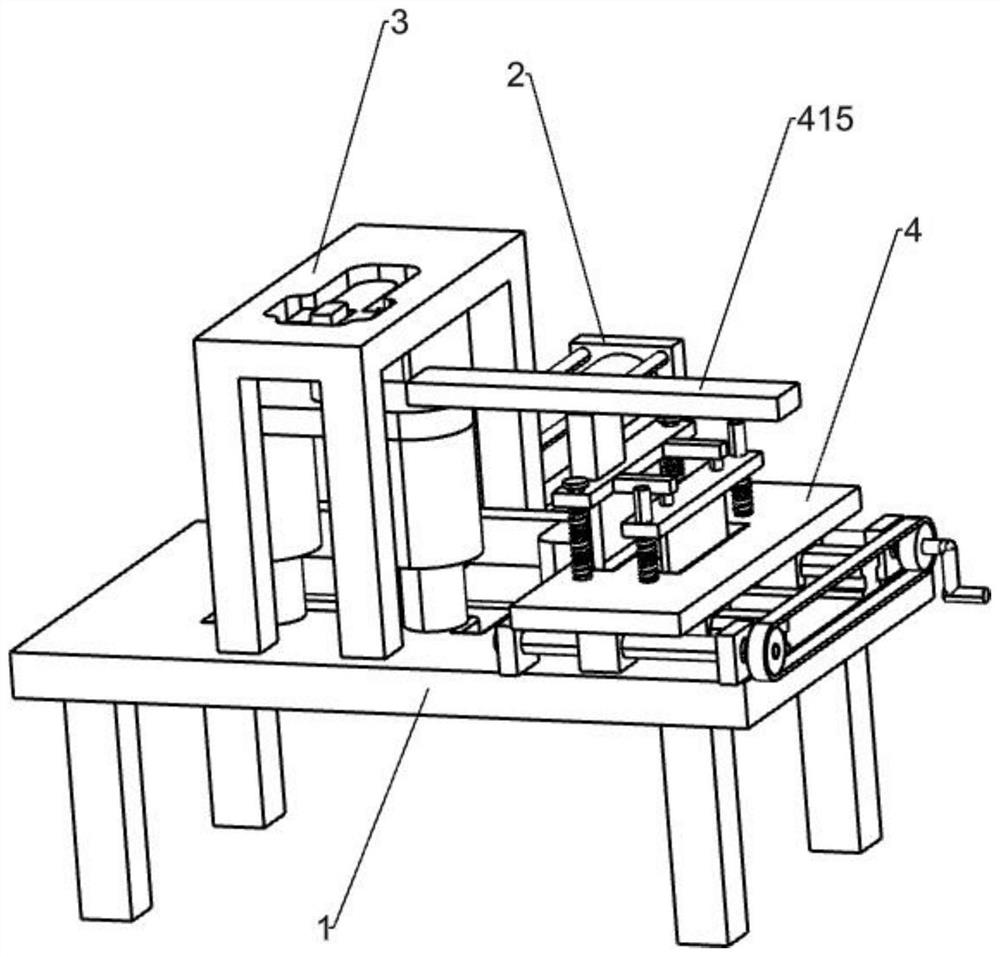

[0029] An automatic thin plate bending equipment for industrial production, such as figure 1 As shown, it includes a workbench 1, a bending mechanism 2 and a pressing mechanism 3. A bending mechanism 2 is installed on the workbench 1. A pressing mechanism 3 is arranged on the workbench 1 outside the bending mechanism 2. The pressing mechanism 3 cooperates with bending mechanism 2.

[0030] When it is necessary to bend the thin plate, the user places the thin plate on the workbench 1 on the lower side of the pressing mechanism 3, and then the user moves the thin plate to the left to a suitable position, and then the user cuts off the thin plate with a suitable length by a cutting machine, and the user passes the bending When the bending mechanism 2 bends the thin plate, the bending mechanism 2 works to make the pressing mechanism 3 work to fix and limit the thin plate, and the user resets the bending mechanism 2, so that the pressing mechanism 3 can be reset to release the fixi...

Embodiment 2

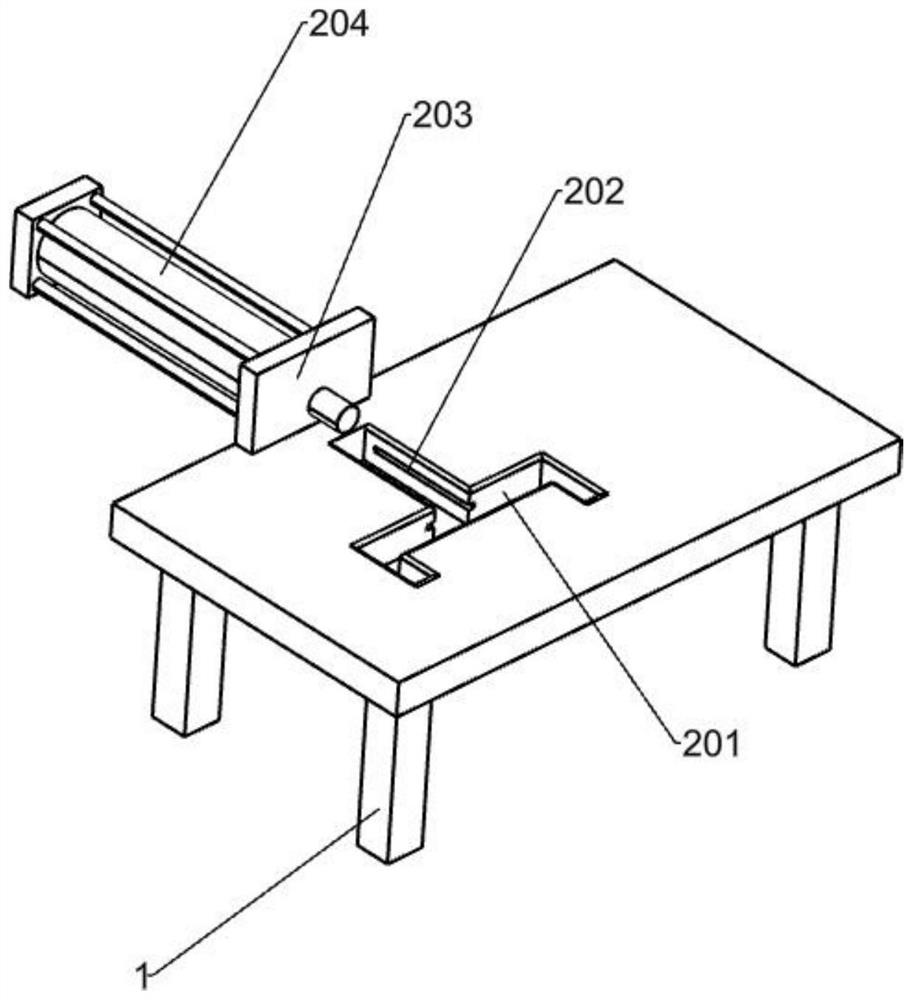

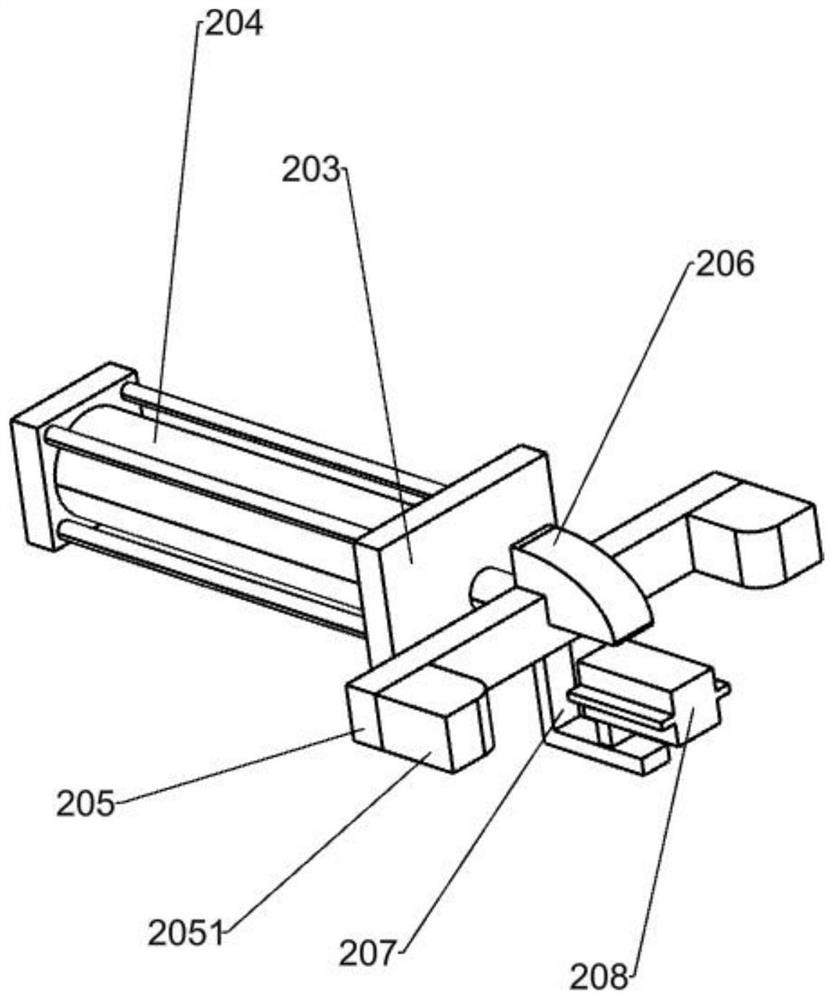

[0032] On the basis of Example 1, as figure 1 , figure 2 , image 3 As shown, the bending mechanism 2 includes a mounting plate 203, a cylinder 204, a push plate 205, a bending block 2051, a bump 206, an L-shaped plate 207 and a slider 208, and the top left side of the workbench 1 has a sliding groove 201 , the workbench 1 on both sides of the slide groove 201 is provided with a linear slide groove 202, and the workbench 1 on the rear side of the slide groove 201 is provided with a mounting plate 203, and a cylinder 204 is installed on the mounting plate 203 through bolts, and the expansion and contraction of the cylinder 204 The rod passes through the mounting plate 203, and the front end of the telescopic rod of the cylinder 204 is fixedly connected with a push plate 205, and two bending blocks 2051 are fixed on the front side wall of the push plate 205, and a projection 206 is embedded in the middle of the top of the push plate 205. An L-shaped plate 207 is fixedly conne...

Embodiment 3

[0037] On the basis of Example 2, such as figure 1 , Figure 7 , Figure 8 and Figure 10 As shown, it also includes a fine-tuning cutting mechanism 4, and the fine-tuning cutting mechanism 4 includes a fixed support 401, a leading screw 402, a connecting nut 403, a connecting plate 404, a guide rail 405, a guide block 406, a pulley 407, a belt 408, a rocker 409, sliding bar 410, sliding plate 411, return spring 412, cutting knife 413, contact plate 414 and lower pressing plate 415, four fixed supports 401 are fixedly connected on the right side workbench 1 of the mounting frame 301, and the left and right two are adjacent A lead screw 402 is installed between the fixed supports 401, and a connecting nut 403 is provided on the lead screw 402 through threaded connection, and a connecting plate 404 is fixed between the tops of the front and rear connecting nuts 403, and the top left of the connecting plate 404 There is a sliding hole 4041 on the side. Two guide rails 405 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com