Automatic assembly mechanism and assembly method for engine accessories for aerospace

An automatic assembly, aerospace technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., to ensure the quality of assembly, meet the requirements of use, and improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

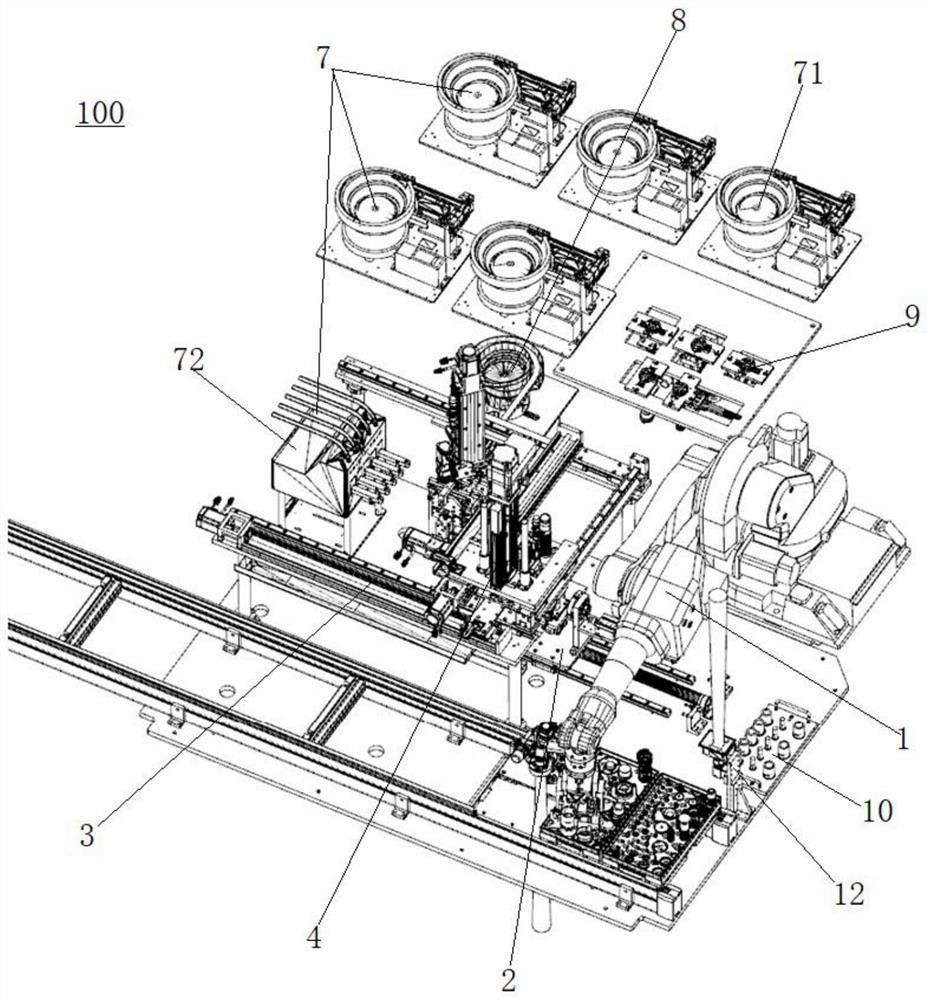

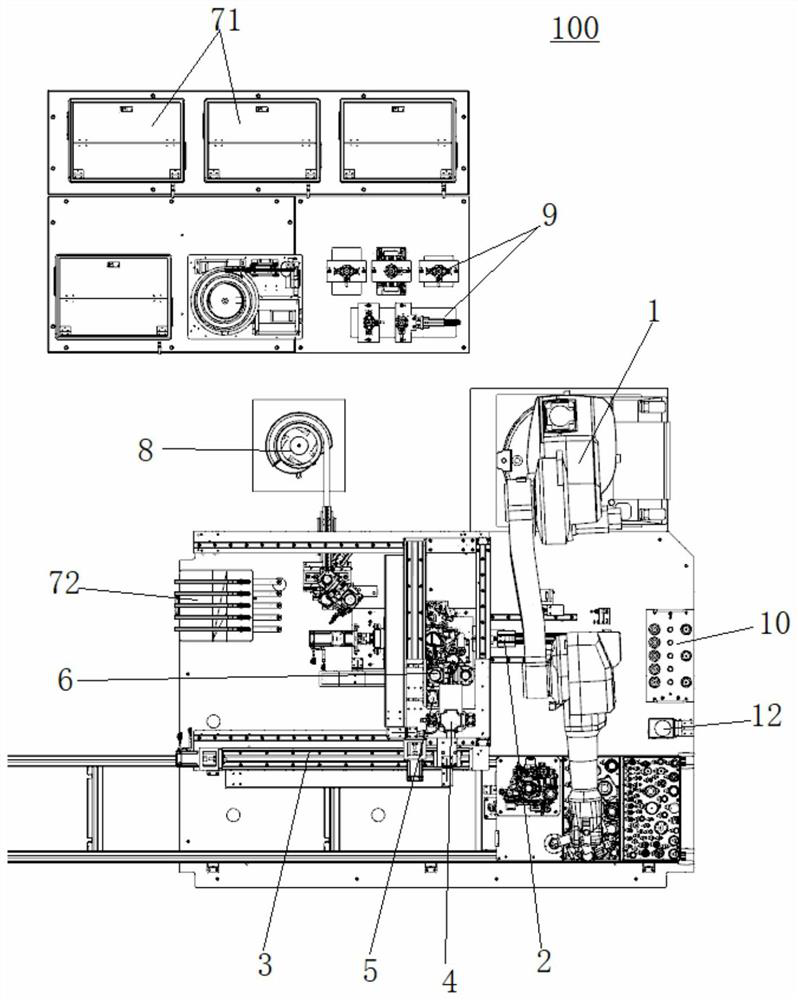

[0059] Please refer to Figure 1-Figure 10 , the present embodiment is an automatic assembly mechanism 100 for aerospace engine parts, which includes a robot handling mechanism 1, a rotating and fixed transfer unit 2 that fixes a workpiece and moves between a loading station and an assembly station, and a horizontal transfer robot 3. The press-fit unit 4 driven by the horizontal transfer robot 3 for XY-axis movement, the gap measurement unit 5 and the locking screw unit 6, the screw feeding unit 7, the locking blade feeding and bending unit 8, and the robot quick change Clamp unit 9 and spacer washer supply unit 10 .

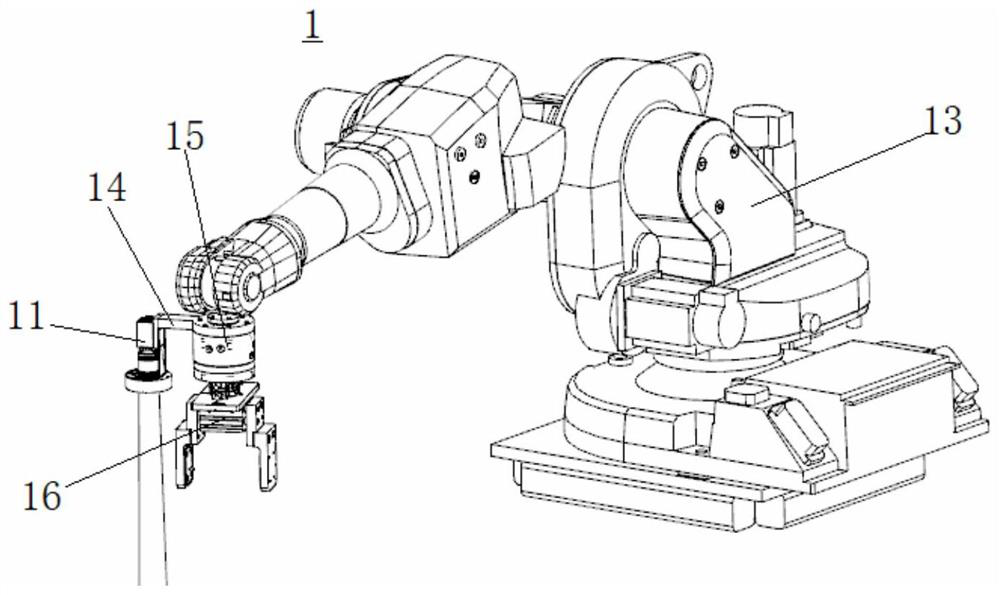

[0060] The robot handling mechanism 1 is mainly used for: 1) taking out the shell from the carrier and placing it on the rotating and fixed transfer unit 2; 2) taking out and installing each component to be assembled from the carrier to the corresponding installation position of the shell 3) Take out the washer or spacer from the spacer washer supply unit 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com