Installation mechanism for implementing installation of valve rod and valve body

A technology of installation mechanism and rod mechanism, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low torque control accuracy, many unqualified products, and large locking torque, etc., and achieves high torque control accuracy. The effect of fewer qualified products and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

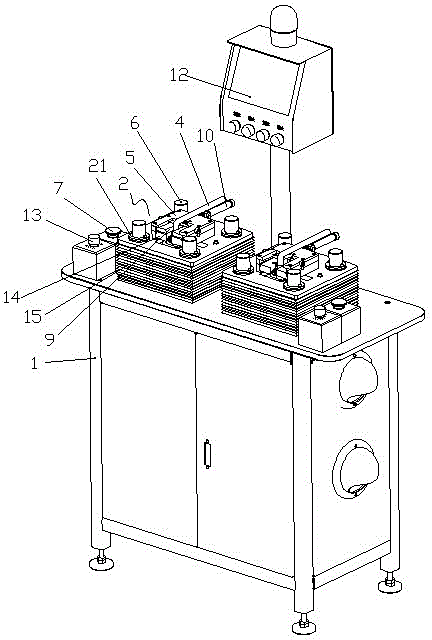

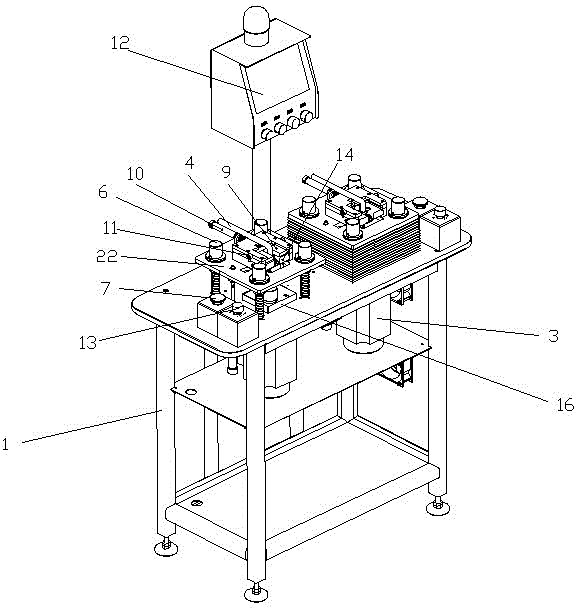

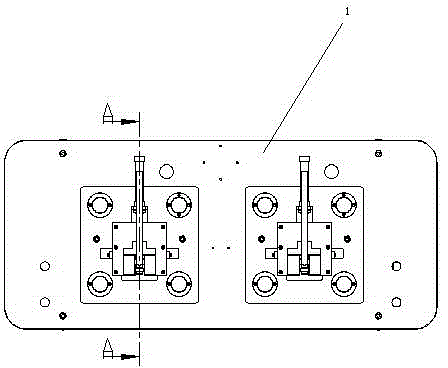

[0023] An installation mechanism for realizing the installation of the valve stem and the valve body described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, it includes a frame 1 and a lock valve rod mechanism 2 placed on the frame. The installation mechanism adopts a double-station design, that is, two symmetrical lock valve rod mechanisms are provided on the frame. The lock valve rod mechanism includes a servo motor 3 fixed on the frame, a clamp 5 that clamps the valve body workpiece 4 and corresponds to the servo motor, a lifting cylinder 6 that can drive the clamp to lift, a PLC programmable controller, and a start button 7 ; The servo motor is positioned at the bottom surface of the frame work surface, the clamps, starting cylinders, etc. are located at the top surface of the frame work surface, and the lifting cylinder passes through the work surface of the frame. The servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com