Soil Throwing Device and Planter after Sowing Wide Seed Belt

A seeder and soil-covering technology, which is applied to agricultural machinery and implements, agriculture, shovels, etc., can solve the problems of increasing seeding rate, high seed damage rate, uncontrollable seeding depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] 1. Description of the structure and operating principle of the whole machine and key components:

[0040] 1. Complete machine and key components:

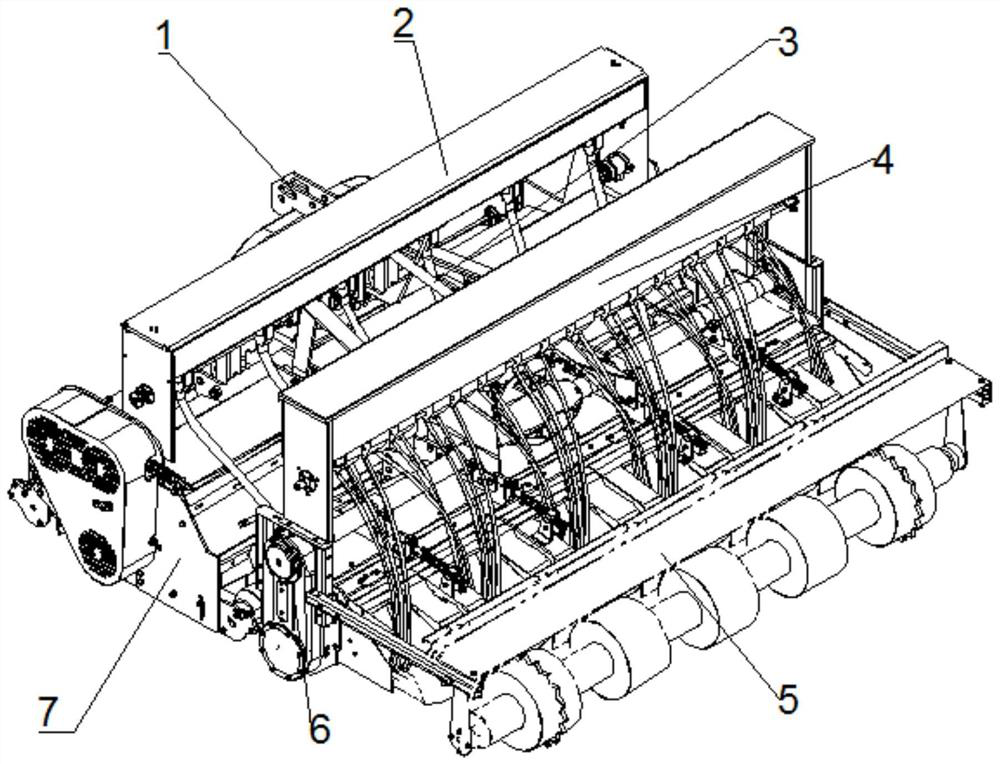

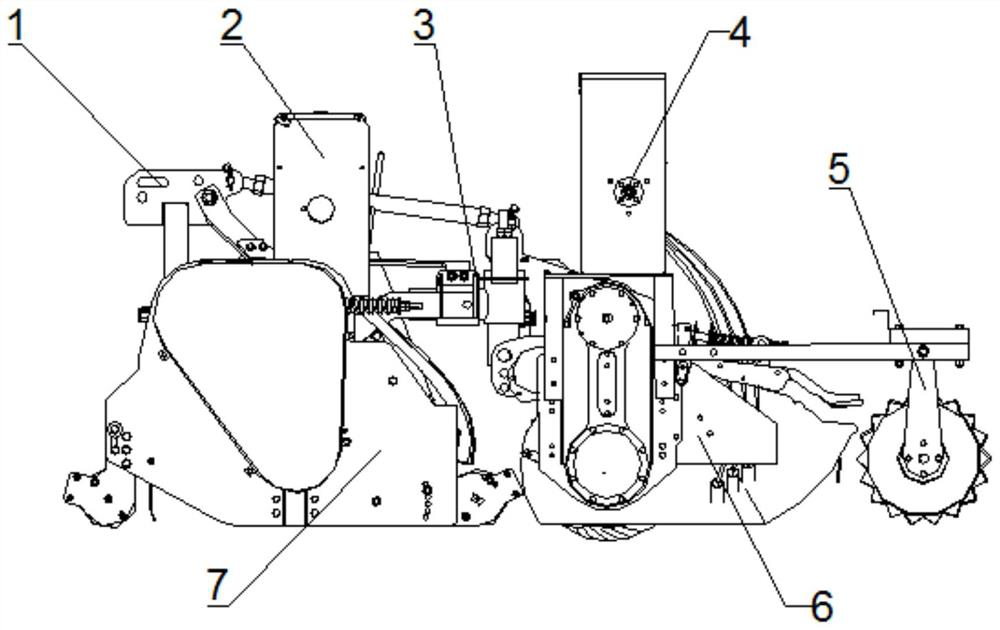

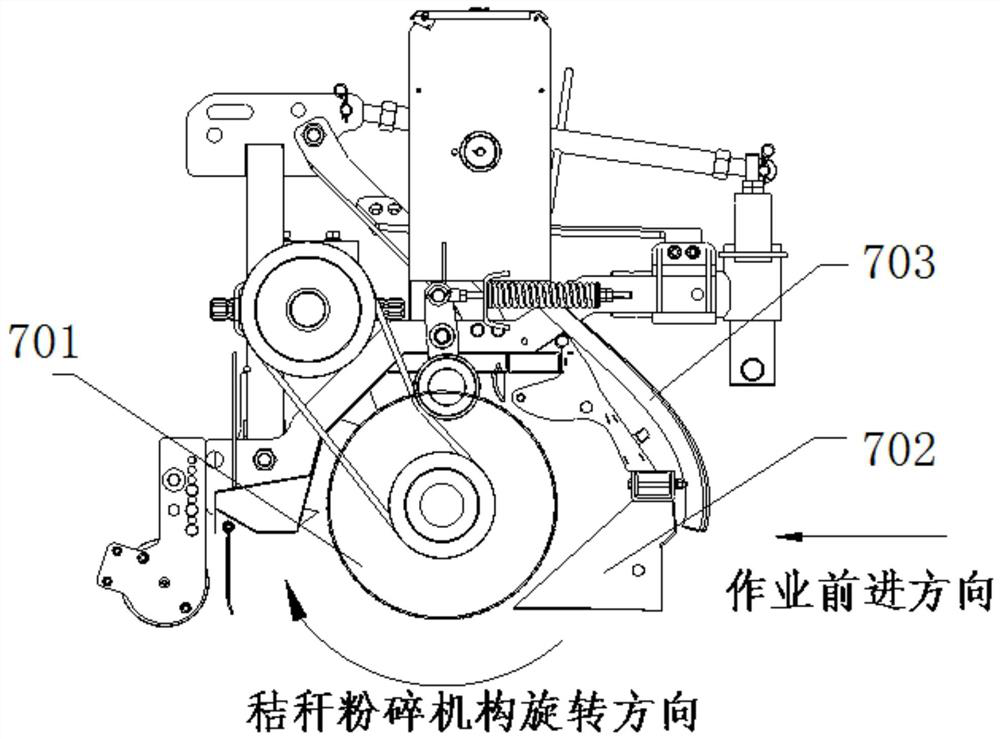

[0041] The wide seed belt pressing wheel assembly 5, the wide seed belt spreading soil throwing device 6, and the straw crushed into strip laying device 7. Such as Figure 1-2 shown.

[0042] The operating parts of the seeder are composed of a soil throwing device 6 after sowing with a wide seed belt, a device 7 for crushing and laying straw into strips, and a pressing wheel assembly 5 with a wide seed belt. The device 7 is hooked by the rear three-point suspension 3, and the wide seed belt suppressing wheel assembly 5 is connected with the throwing soil device 6 after the wide seed belt is sown by bolts. The straw is crushed into strips and placed above the device 7. Kind box 4 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com