Proton exchange membrane fuel cell water management system and operation method

A fuel cell water and proton exchange membrane technology, applied in fuel cells, fuel cell additives, fuel cell control, etc., can solve the problems of excessive water, increased internal resistance, imbalance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

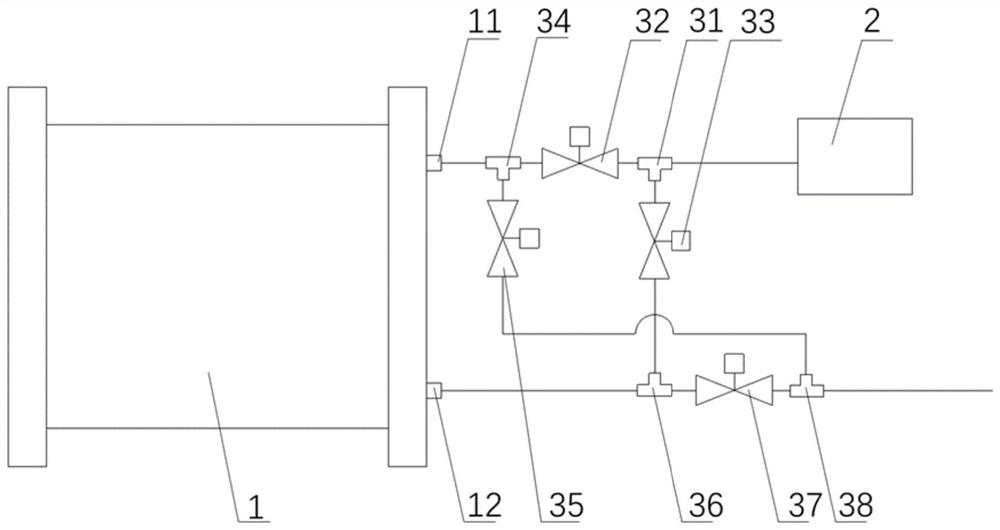

[0027] Such as figure 1 As shown, a proton exchange membrane fuel cell water management system according to Embodiment 1 of the present invention includes the following components: 1-proton exchange membrane fuel cell; 11-battery cathode inlet; 12-battery cathode outlet; 2-cathode feeding system 31-the first three-way; 32-the first solenoid valve; 33-the second solenoid valve; 34-the second three-way; 35-the third solenoid valve; 38 - The fourth tee.

[0028] One end of the first tee 31 in the water management system is connected to the cathode supply system 2 of the fuel cell through a pipeline, and the other two ends are respectively connected to the first solenoid valve 32 and the first solenoid valve 32 of the water management system through pipelines. The second solenoid valve 33; the other end of the first solenoid valve 32 in the water management system is connected to the second three-way 34 through a pipeline; the other two ends of the second three-way 34 in the wate...

specific Embodiment 2

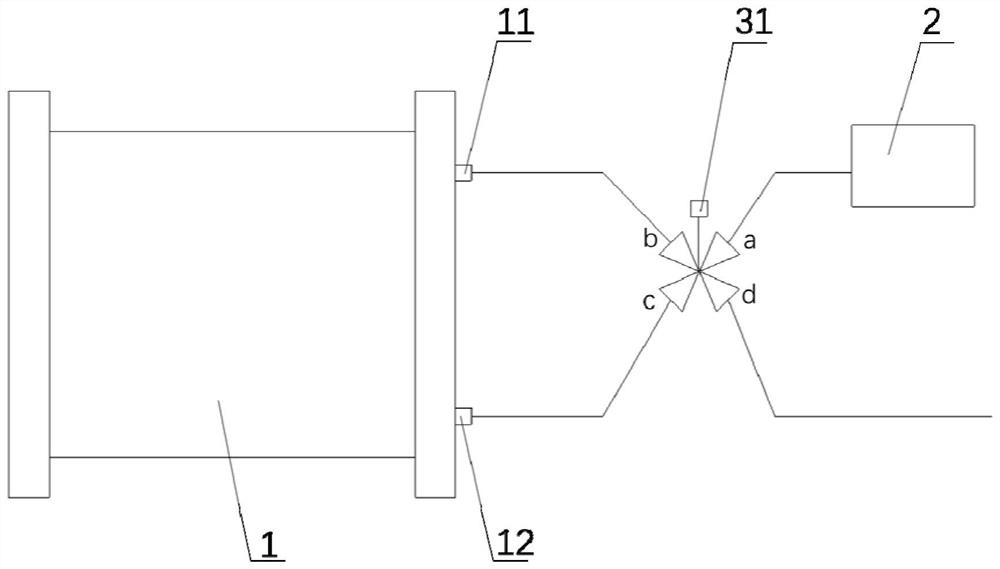

[0035] Such as figure 2 As shown, a proton exchange membrane fuel cell water management system according to Embodiment 2 of the present invention includes the following components: 1 - proton exchange membrane fuel cell; 11 - battery cathode inlet; 12 - battery cathode outlet; 2 - cathode feed system 31-four-way valve.

[0036] Depend on figure 2 It can be seen that the four outlets a, b, c, and d of the four-way valve are respectively connected to the fuel cell cathode feed system 2, the fuel cell cathode inlet 11, the fuel cell cathode inlet 12, and the discharge pipeline.

[0037] The operation method provided by this specific embodiment is as follows:

[0038] State one is that in the four-way valve 31, the a end communicates with the b end, and the c end communicates with the d end; after the cathode oxidant gas (air or oxygen) passes through the cathode feed system 2, it passes through the four-way valve 31 end a and b end of the fuel cell, as well as the fuel cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com