A method to establish a model for characterizing the change of coal blending cost

A change model, coal blending technology, applied in data processing applications, forecasting, instruments, etc., can solve the problems of limited production of coke ovens, poor quality stability, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

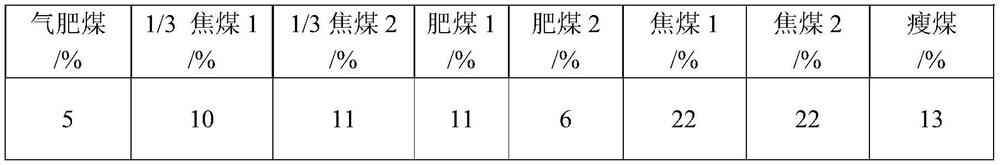

[0065] According to the current coal blending plan of a coking plant, the annual dry coal consumption is 5 million tons, and the annual coke shortage is 20,000 to 50,000 tons. It is necessary to adjust the coal blending plan to increase the coke production capacity, while controlling the coal blending cost, and requires coke quality CSR >67%, M 40 >86%, M 10 <6.2%.

[0066] The types of coal used in the coking plant: gas fertilizer coal, 1 / 3 coking coal 1#, 1 / 3 coking coal 2#, fat coal, coking coal 1#, coking coal 2#, lean coal.

[0067] Table 1 Single coal quality

[0068] coal sample V daf / %

Ad / % S / % G Y / mm lgMF Gas fat coal 40.23 7.41 1.61 98 26 4.7 1 / 3 coking coal 1# 31.45 9.93 0.52 88 17 3.3 1 / 3 coking coal 2# 35.26 7.52 0.61 87 17 3.1 Fat coal 1# 30.65 9.12 1.46 95 26 4.1 Fat coal 2# 34.68 7.81 0.45 98 27 4.3 Coking coal 1# 24.56 9.72 0.45 84 17 2.5 Coking coal 2# 23.56 9.51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com