Superheated steam temperature prediction method based on multi-innovation stochastic gradient optimization

A technology of superheated steam temperature and random gradient, applied in design optimization/simulation, computer-aided design, instrumentation, etc., can solve problems such as slow convergence speed, small calculation amount, and inability to control steam temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

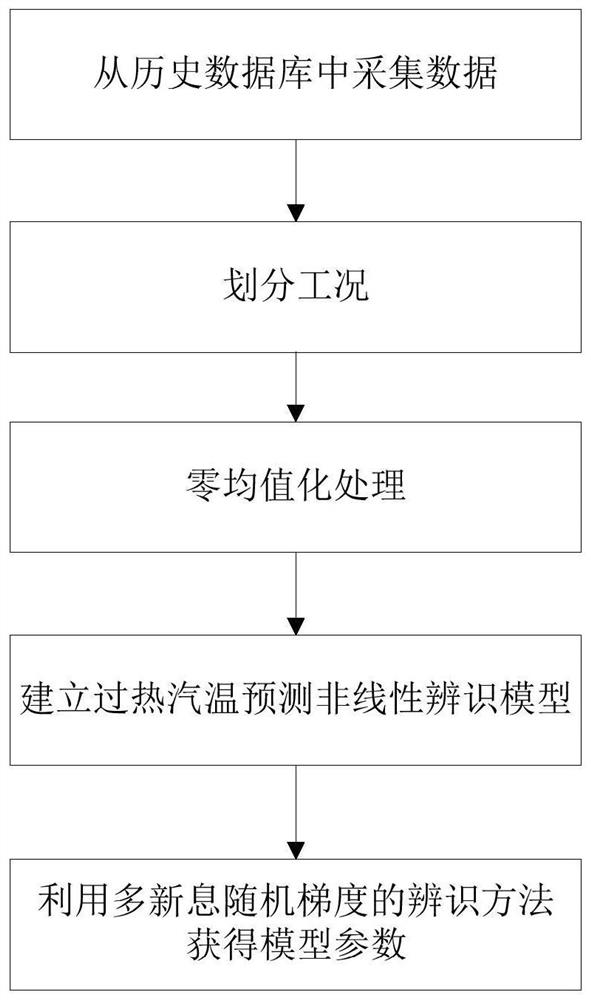

[0067] like figure 1 As shown, the present invention provides a superheated steam temperature prediction method based on multi-innovation stochastic gradient optimization, which specifically includes the following steps:

[0068] (1) Divide the working conditions according to the unit load, choose 20% of the full load as the selection principle of the load section, and determine 3 typical working conditions from 45% to 100% of the full load;

[0069] (2) Read the steam temperature at the inlet of the final superheater and the steam at the outlet of the final superheater during normal operation under each load condition from the DCS history database as the training sample TX, and the sampling time is 60s;

[0070] (3) Preprocess the training sample TX so that the mean value of each variable is 0, and the input matrix X∈R is obtained N×n ;Specific steps are as follows:

[0071] (3-1) Calculate the mean:

[0072] (3-2) Zero mean processing:

[0073] Among them, TX is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com