Device, system and process for detecting and positioning aluminum electrolysis cell ground faults

An aluminum electrolytic cell and positioning device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of lack of safety measures, hidden dangers, inaccurate fault location, etc., to improve current efficiency, reduce costs, improve The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the device for detecting and locating aluminum electrolytic cell faults and its system and process of the present invention will be described in detail with reference to exemplary embodiments.

[0037] In order to better illustrate the present invention, the inventor modeled the electrolytic cell of an aluminum electrolytic plant and its power supply mode.

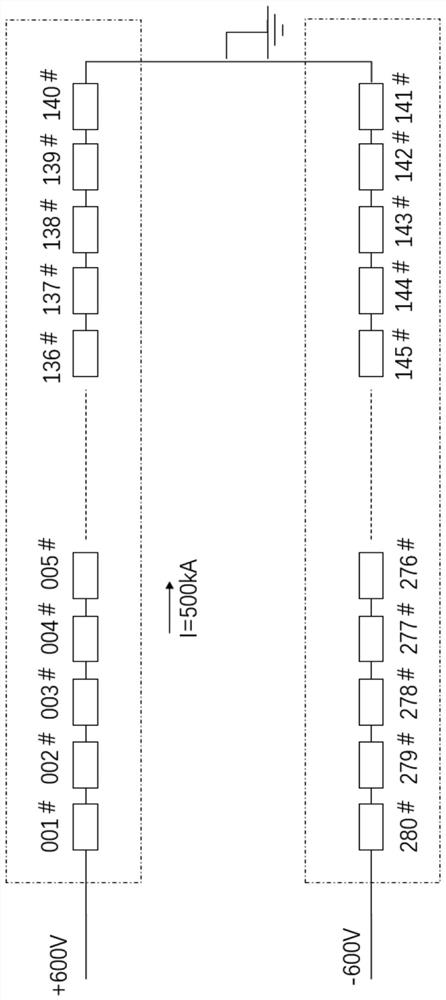

[0038] figure 1 A schematic diagram of the current electrolytic cell and its power supply mode of an aluminum electrolysis plant is shown.

[0039] Such as figure 1As shown, the power supply mode of the aluminum electrolytic cell is a special ungrounded DC power supply system, the DC power supply is ±600V, and its powerful current is formed by a series of busbars and the electrolytic cell. Among them, 001#~140# electrolytic cells are located in the first workshop, and 141#~280# electrolytic cells are located in the second workshop.

[0040] Under normal circumstances, when the electrolyzer is well in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com