Liquid level visual display warning device

A warning device and intuitive technology, applied in the direction of the buoy liquid level indicator, etc., can solve the problems of difficult replacement, affecting the detection effect, and inability to be intuitive for long-distance transmission, so as to achieve convenient maintenance or replacement, safe and reliable detection system data, Timely and convenient maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

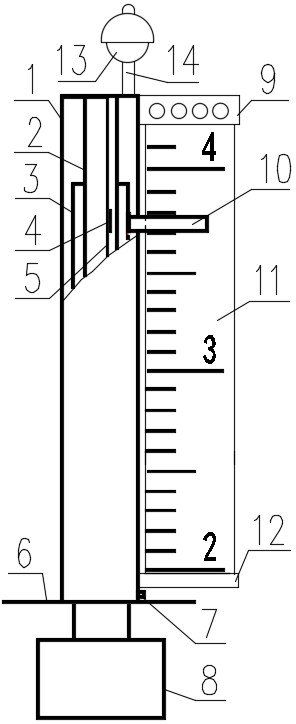

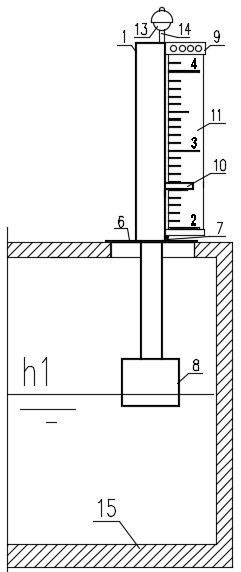

[0021] figure 1 , which is a schematic diagram of the main structure of the device; the structure system of the device includes systems such as float scale liquid level detection, liquid level automatic control detection warning set video visualization and other systems. Such as figure 1 As shown, the components of the float scale liquid level detection system include a scale column 1, a guide pipe 2, a connecting pipe 3, a base plate 6, a float 8, an indicator 10, and a scale 11; the lower part of the scale column 1 is located at On the base plate 6, the upper part of the scale column 2 is connected with the upper part of the guide pipe 2; the lower part of the guide tube 2 is inserted into the connecting pipe 3 and guided therefor, and the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com