Constant-temperature circulating valve and mounting and using method thereof

A circulating valve and constant temperature technology, applied in the valve device, valve operation/release device, application, etc., can solve the problems such as the inability to effectively prevent the growth of Legionella, the temperature of the circuit water, and the uneven heating and cooling of the water outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

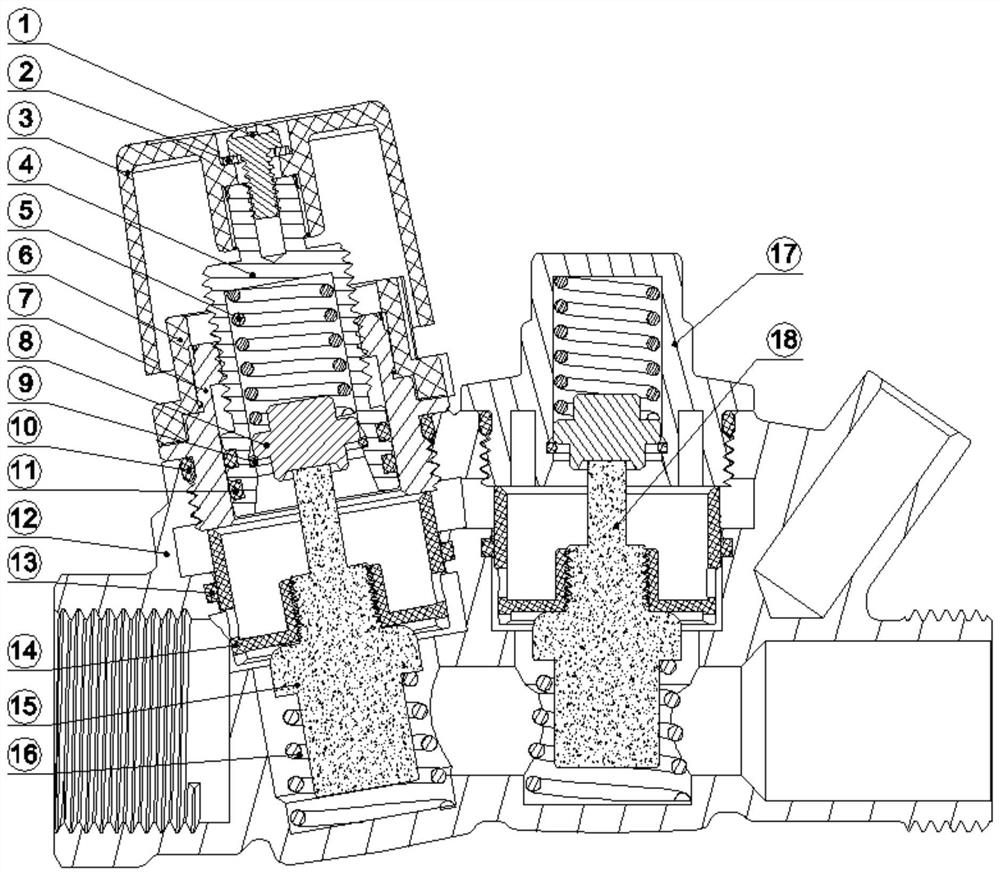

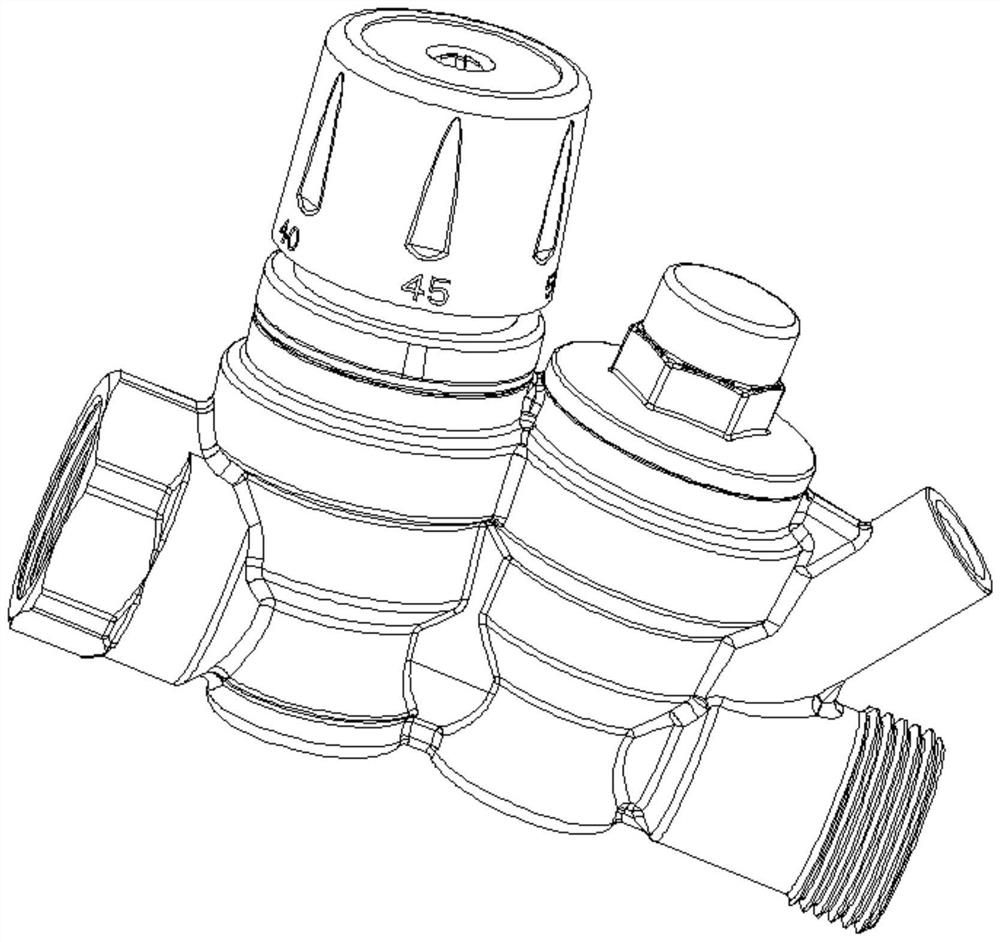

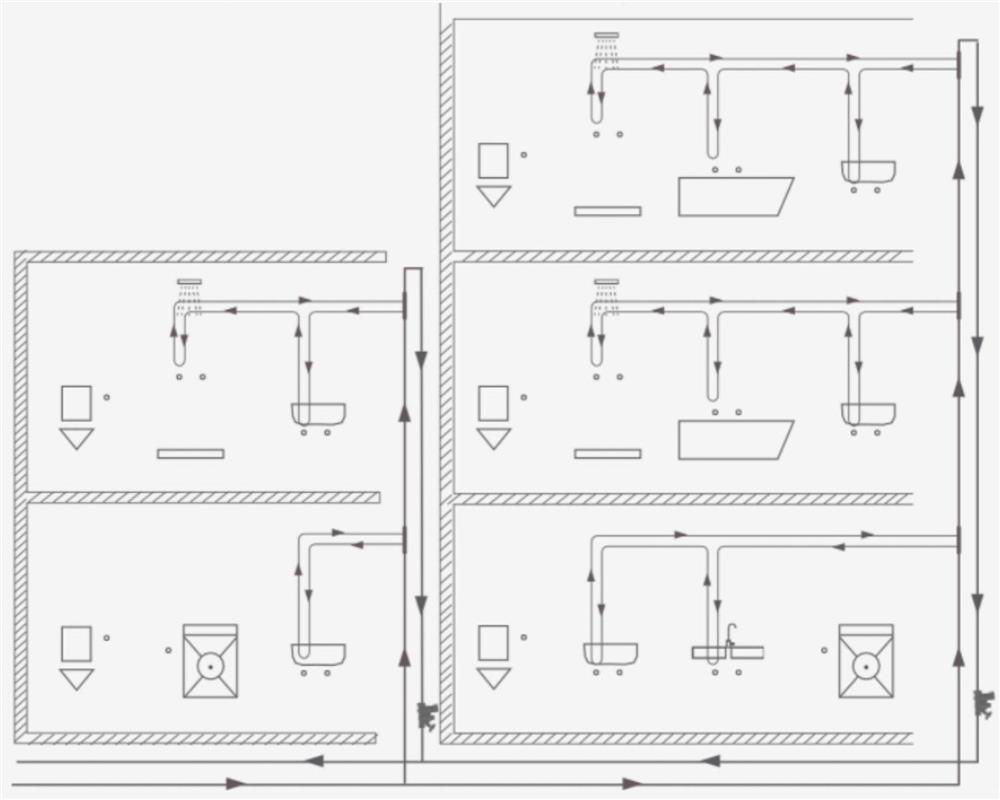

[0034] refer to Figure 1-5 , a constant temperature circulation valve, including a valve body 12, the valve body 12 is respectively provided with a temperature regulating package 15 and a sterilization temperature package 18, and the lower ends of the temperature regulation package 15 and the sterilization temperature package 18 are both provided with a working spring 16 to adjust the temperature The middle of the bag 15 and the sterilization temperature bag 18 are respectively provided with a control piston 14 and a bypass piston. The built-in temperature control bag 15 automatically adjusts the flow through the valve body 12 according to the water temperature. When the water temperature is close to the set temperature, the temperature is adjusted. Packet 15 gradually reduces the flow, so that the circulation system flow can be distributed to other outlets of the system to achieve the effect of rapid constant temperature balance flow. The upper ends of the regulating temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com