A kind of conical building and construction method thereof

A construction method and building technology, applied in the direction of building structure, building, roofing, etc., can solve the problems of increased difficulty in structural design and construction, high requirements for component processing precision, and self-heavy beam structures, etc., to achieve good lighting, The effect of low processing difficulty and small number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

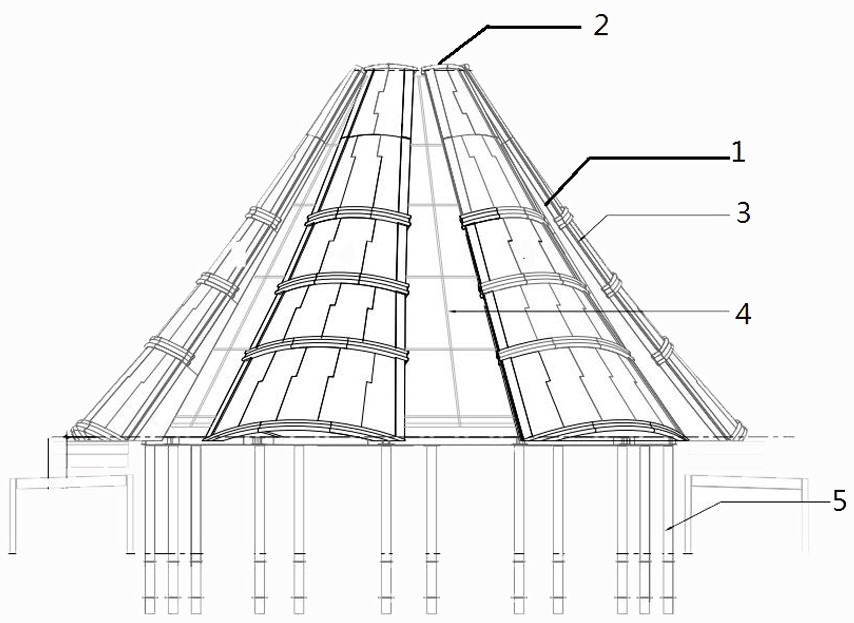

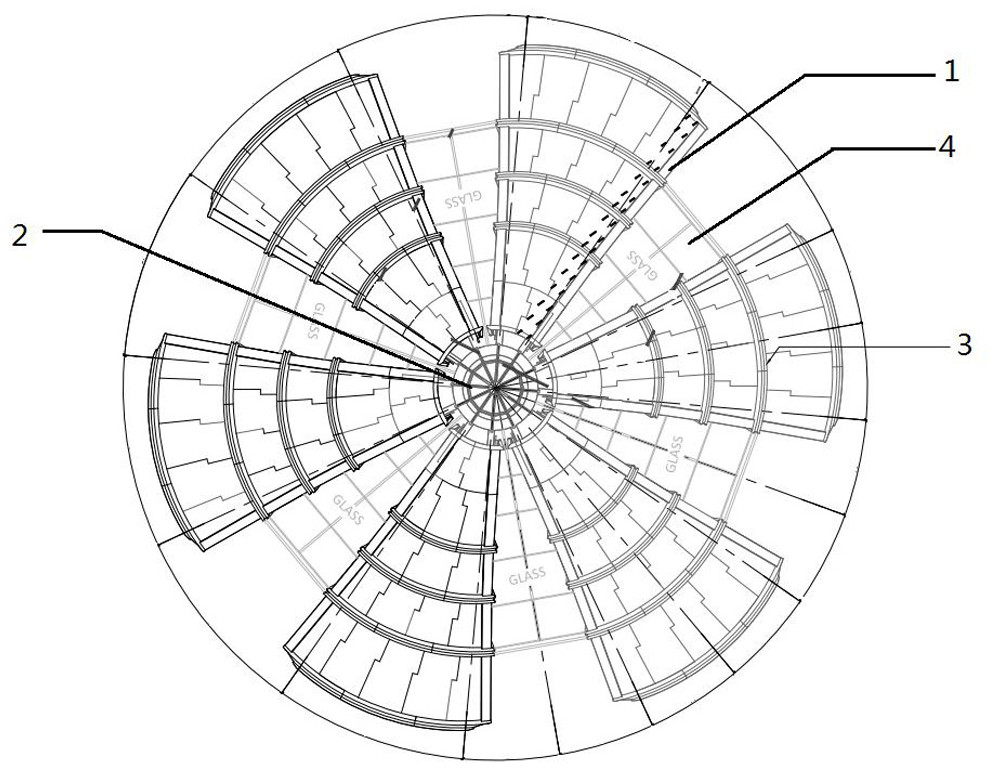

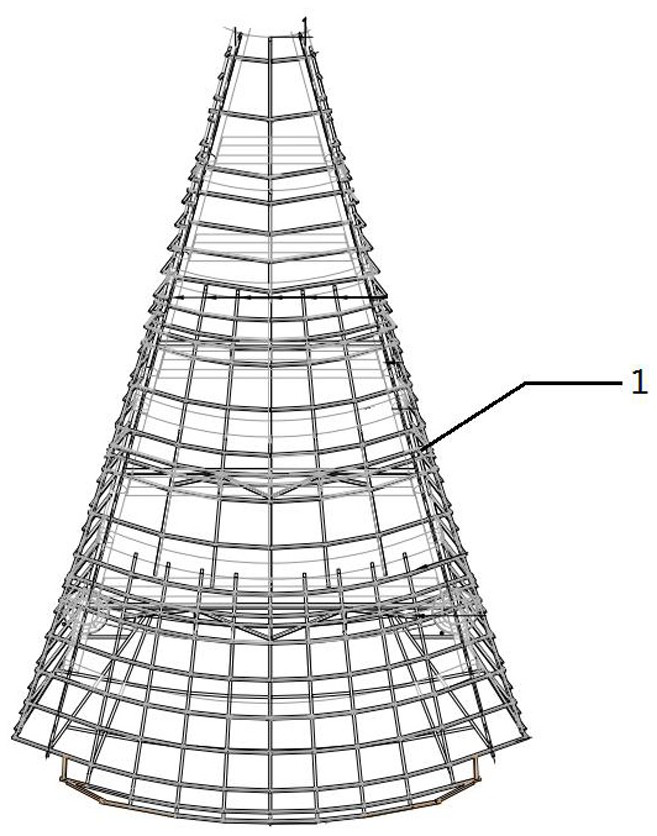

[0041] Figure 1-5 A tapered building showing an embodiment of the present invention comprising radiating beams 1, a central ring beam 2, a sun visor 3, a skylight frame 4, and a steel joist 5, the top of the radiating beam 1 and the central ring beam 2 Connected and radially arranged from the central ring beam 2 to the surroundings, the bottom of the radial beam 1 is connected to the steel structure keel 5, the steel structure keel 5 is connected to the foundation concrete structure, and the sunshade 3 is arranged uniformly along the outer surface of the radial beam 1 Set at least three pieces at intervals, the top of the sun visor 3 is connected to the central ring beam 2, the bottom of the sun visor 3 is connected to the steel structure keel 5, and the skylight frame 4 is connected to the radial beam 1 between the gaps between adjacent sun visors 3 , the sun visor 3 is an arc-shaped plate whose edge is bent toward the interior of the building, the outer surface of the sun v...

Embodiment 2

[0043] Such as Figure 6-7 Shown, the construction method of the tapered building of above-mentioned embodiment of the present invention, following steps,

[0044] Step 1: Build the main steel structure, install the steel structure keel (5) on the foundation concrete structure, and install the radial beam (1), roof rafters (6) and central ring beam (2) in sequence, after building the main steel structure , carry out 3D scanning correction, on the basis of the 3D scanned model drawing, use BIM to deepen the secondary structure and FRP components, improve the accuracy of the components, and form a detailed design drawing; process the component plate according to the deepening design drawing, Enter the production and coloring stage of the component board;

[0045] Step 2: Fabrication and coloring of the component plate. The production of the component plate includes master mold making, mold making, component plate turning and component plate demoulding;

[0046] The master mode...

Embodiment 3

[0072] The construction method of the tapered building of the above-mentioned embodiment of the present invention can also be improved as follows,

[0073] 1. Process flow

[0074]Measuring and setting out→Installation of mold expansion bottom anchor bolts (secondary steel structure installation)→Installation of embedded plates on the secondary structure→Assembly fittings→Installation of plug-in parts→Optional component plates and lifting→In-place installation of component plates, Bolt connection→correction and adjustment of component plates→measurement inspection→fixing bolts (welding and fixing)→gluing plate seams (if necessary) sills, repairs→maintenance→sub-item acceptance.

[0075] 2. Operation points

[0076] 2.1 Measurement and setting out

[0077] (1) Measuring and setting out: use ink line to pop up the benchmark on the outer wall and outer beam, and review its structural deviation. Eject the center cross of the adapter with an ink line on the exterior wall surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com