Open drainage ditch process by internal mold method mortar masonry

An open drainage ditch technology, applied in the field of drainage ditch construction, can solve problems such as difficulty in controlling the surface smoothness of the line shape of the drainage ditch, poor appearance quality, and uneven thickness of masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

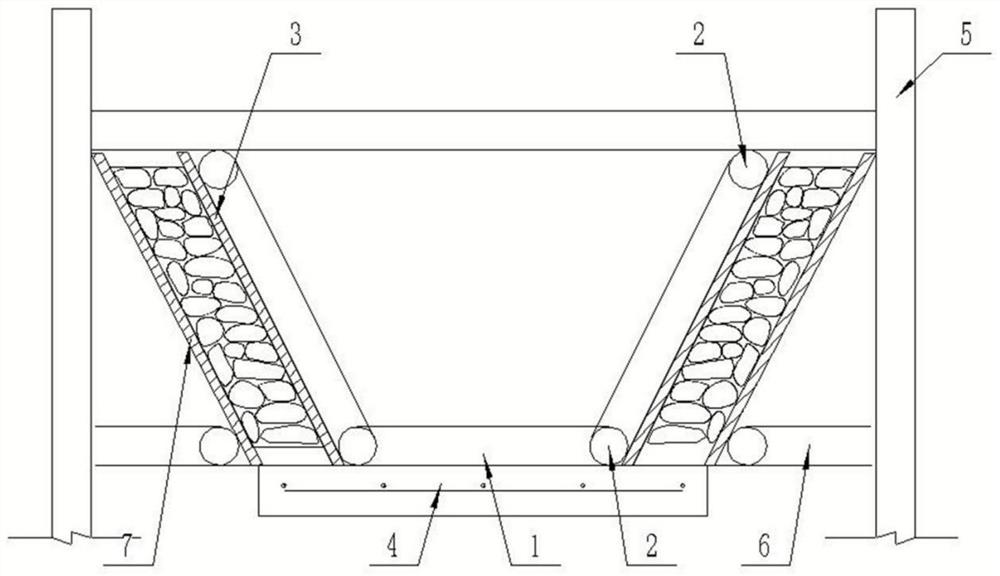

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

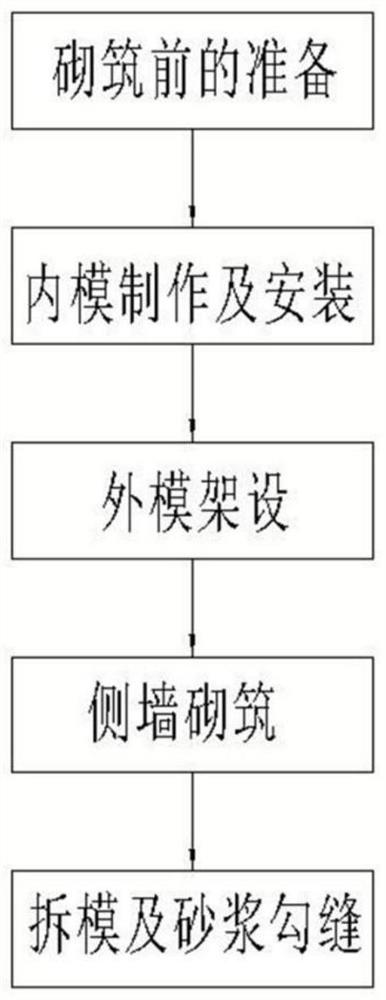

[0034] Such as Figure 1 to Figure 2 As shown, a kind of internal mold method slurrying open drainage ditch process, the specific steps are:

[0035] S1. Preparations before masonry

[0036] Clean up the concrete floor 4 that has been cured, and clean up the sundries and soil on it to prevent an isolation layer from appearing between the wall and the wall, which will affect the bonding effect;

[0037] Accurately measure and release the center line, and the construction personnel pop out the center line with ink according to the measured center line point;

[0038] S2. Inner mold making and installation

[0039] Make the supporting inner mold according to the shape of the drainage ditch, the structure of the inner mold includes several parallel trapezoidal supports 1 with a wide top and a narrow bottom, and scaffolding is welded on both sides of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com