Labor-saving conveying device for conveying materials

A handling device and labor-saving technology, which is applied in the direction of lifting devices, transportation and packaging, conveyors, etc., can solve the problems of inconvenient operation of transportation equipment, inconvenient loading and unloading, etc., and achieve the effect of uniform transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

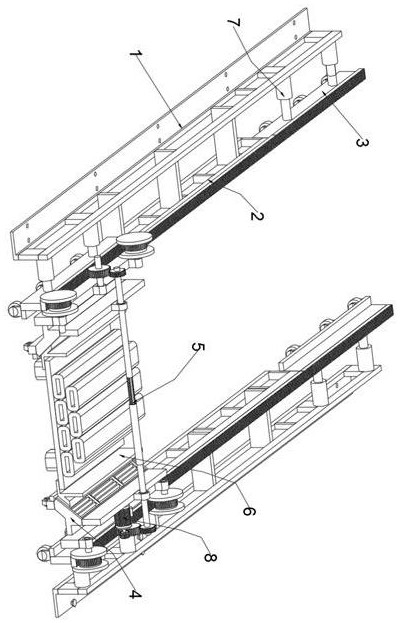

[0035] as attached figure 1 to attach Figure 10 Shown:

[0036]The invention provides a labor-saving handling device for material handling, which includes a conveying frame 2, a lifting frame 4, a synchronous shaft 5, a hydraulic cylinder 7, a driving part 8, and a universal wheel 10; the conveying frame 2 is fixedly connected by a welding bracket In the inner middle position of the two installation frames 1, a transmission rack 201 is provided on the upper surface of the transport frame 2, and the transmission rack 201 on the upper surface of the transport frame 2 is parallel to the ground, passing through the transport frame 2 and the rear support frame 402 The cooperation of the lifting frame 4 can realize the movement of the lifting frame 4 above the conveying frame 2 to realize the transfer of goods. The length of the conveying frame 2 can be determined according to the needs of the site; the cylinder body of the hydraulic cylinder 7 is fixedly connected to both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com