Pattern printing machine

A printing press and printmaking technology, applied in the field of printmaking printing presses, can solve the problems of unshaped printed objects and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

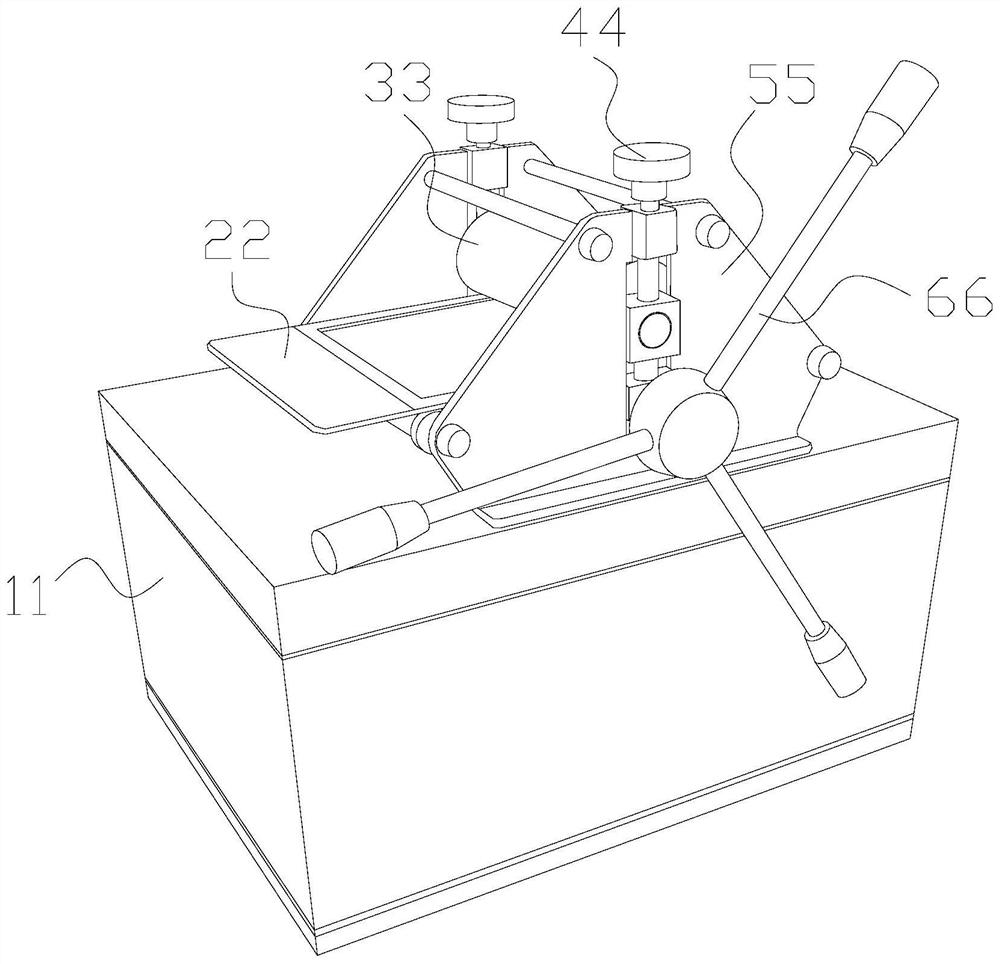

[0032] as attached figure 1 to attach Image 6 Shown:

[0033] The present invention provides an engraving printing machine, the structure of which comprises a bottom box 11, a bottom platen 22, a roller 33, a height adjustment rod 44, a side support plate 55, and a rotating rod 66, and the side support plate 55 is vertically welded to the bottom box 11 On the upper surface, side support plates 55 are installed at both ends of the roller body 33, the height adjustment rod 44 is fixedly connected with the side support plate 55, the bottom pressure plate 22 is located below the roller body 33, and the rotating rod 66 is connected to the height adjustment rod 55. Rod 44 is connected.

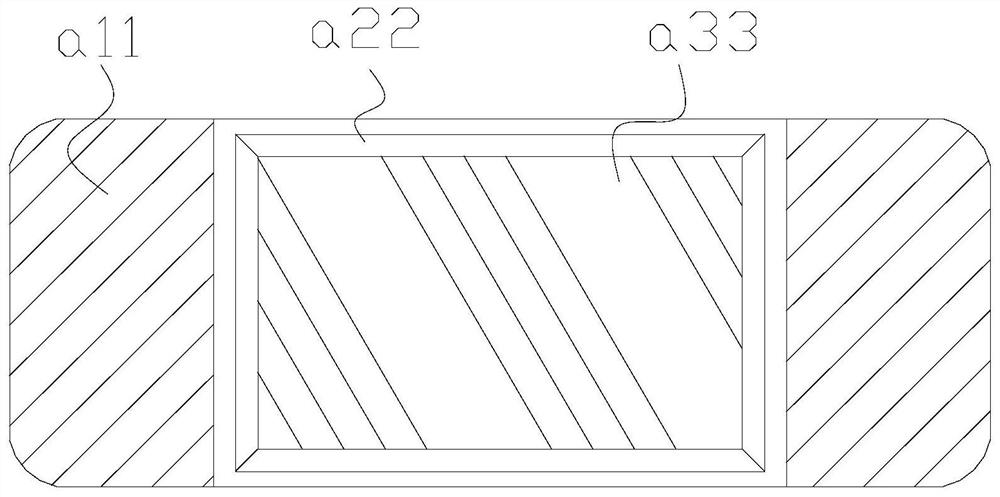

[0034] The bottom platen 22 includes an extension plate a11, a glue port a22, and a built-in groove a33. The built-in groove a33 and the extension plate a11 are an integrated structure, and the glue hole a22 is installed on the inner wall of the built-in groove a33.

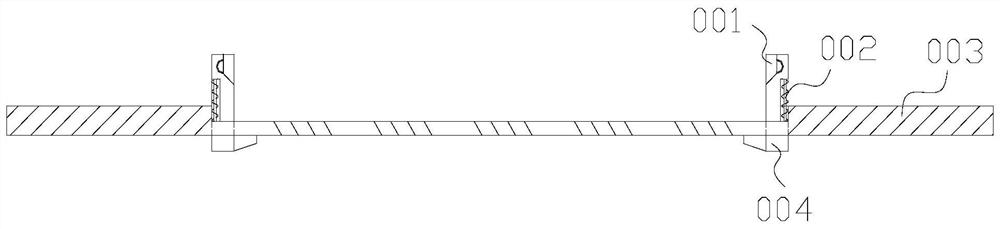

[0035] Wherein, the rubber ...

Embodiment 2

[0042] as attached Figure 7 To attach Figure 9 Shown:

[0043] Wherein, the epitaxial layer e22 includes a support body x10 and a spacer bar x20, the spacer bar x20 is installed between two support bodies x10, there are two spacer bar x20, and the spacer bar x20 The supporting body x10 bears external force in a large area at intervals at the overall stress-bearing part.

[0044] Wherein, the support x10 includes an outer covering g1, a corner g2, and a soft corner core g3, the corner g2 is attached to the outer surface of the soft corner core g3, and the soft corner core g3 is embedded inside the outer wrapping body g1 , the soft angle core g3 is a triangular structure, the interval angle g2 is a V-shaped structure, the interval angle g2 guides the stress tendency of the spaced parts, and the outer covering g1 limits the installation range of the inner parts.

[0045] Wherein, the soft corner core g3 includes a coating layer s11 and a soft elastic core s22. The soft elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com