Overturning platform for production of external wall panel for fabricated building

A technology of hanging wall panels and turning platforms, which is applied to workbenches, lifting devices, lifting frames, etc., can solve the problems of heavy weight of external wall panels, reducing work efficiency, trouble, etc., to increase work efficiency, simple device structure, and easy to use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

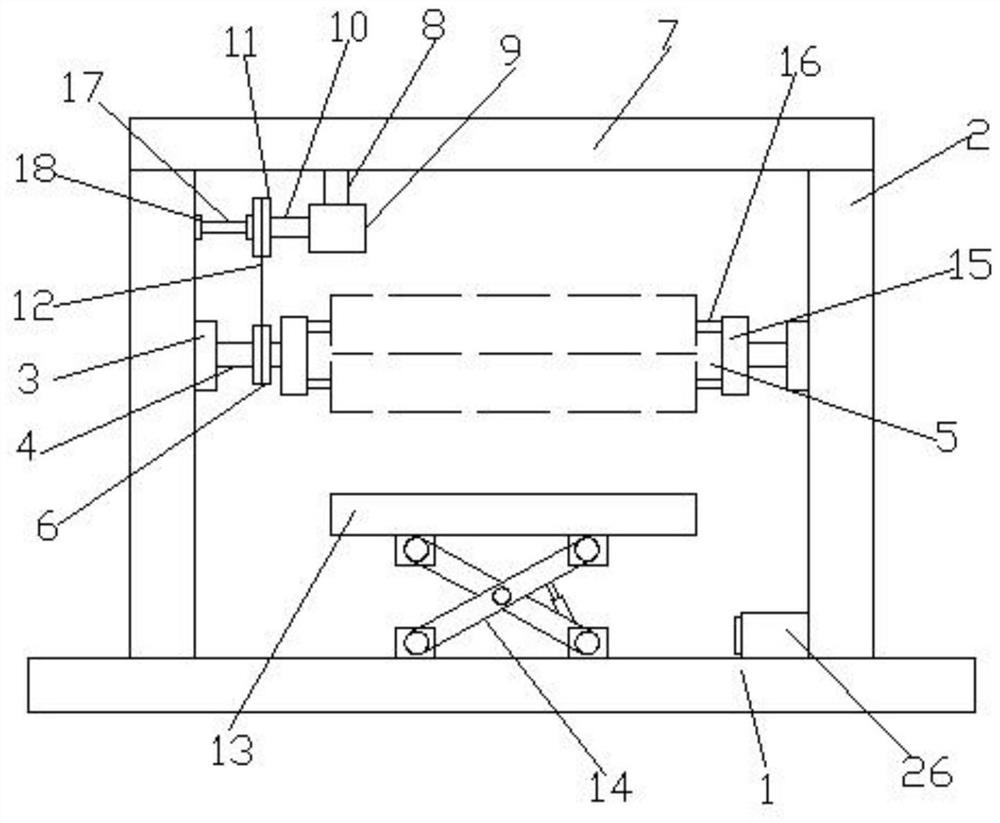

[0027] see Figure 1-2 According to an embodiment of the present invention, a flipping platform for the production of external wall panels for prefabricated buildings includes a fixed base plate 1, and side plates 2 are symmetrically arranged on the fixed base plate 1, and first Bearings 3, rotating shafts 4 are fixed on the inner ring of the first bearing 3, and a first sprocket 6 is provided on one of the rotating shafts 4, a clamping mechanism 5 is connected to the rotating shaft 4, and the side plate 2 A horizontal plate 7 is arranged between them, and a motor 9 is fixed on the side of the horizontal plate 7 close to the first sprocket 6 through a fixed rod 8, and the output end of the motor 9 is provided with a transmission shaft 10. The top of the transmission shaft 10 is provided with a second sprocket 11, a transmission chain 12 is provided between the first sprocket 6 and the second sprocket 11, and a workbench 13 is provided above the fixed base plate 1. A lifting d...

Embodiment 2

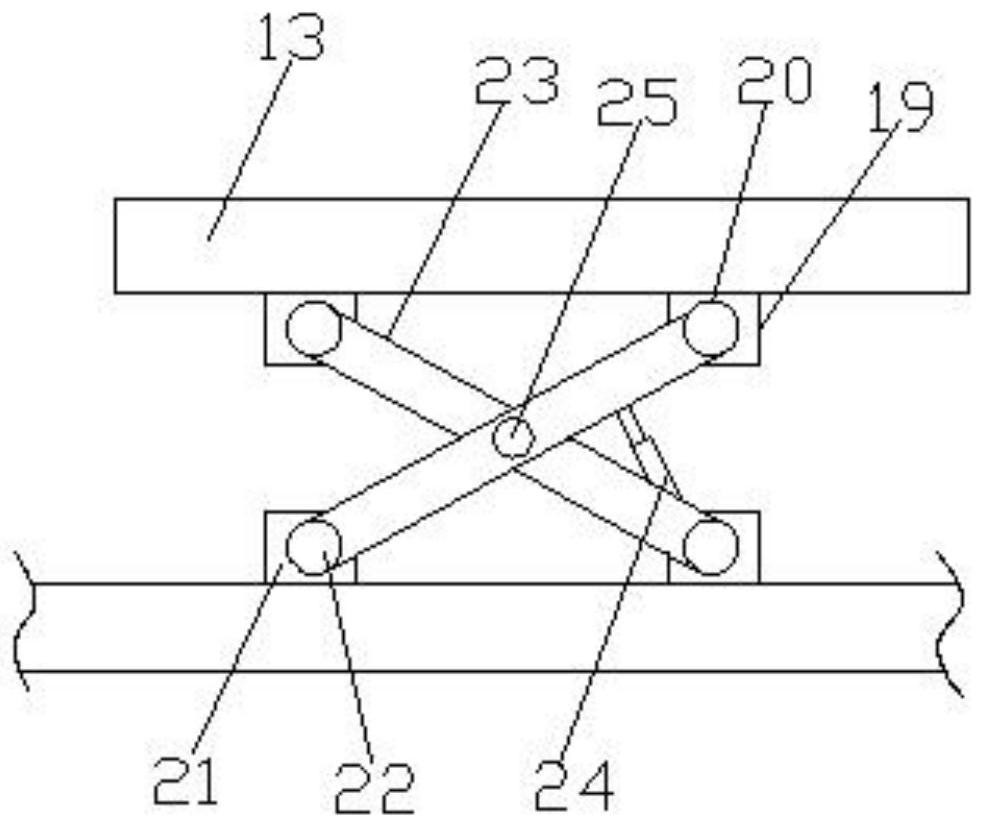

[0030] Such as Figure 1-2 As shown, the clamping mechanism 5 includes a hydraulic cylinder 15, the hydraulic cylinder 15 is provided with a first hydraulic telescopic rod 16, and the hydraulic cylinder 15 drives the first hydraulic telescopic rod 16 to clamp the external wallboard; The side of the second sprocket 11 away from the transmission shaft 10 is provided with a fixed rod 17, and both ends of the fixed rod 17 are provided with second bearings 18, and the second bearings 18 are respectively fixed on the side plates 2 And on the second sprocket 11, the second sprocket 11 can be played a stable role; the lifting device 14 includes a first fixed block 19 symmetrically fixed on the bottom of the workbench 13, on the first fixed block 19 A first movable shaft 20 is provided, a second fixed block 21 is arranged below the fixed bottom plate 1, and a second movable shaft 22 is arranged on the second fixed block 21, and the second movable shaft 22 is connected to the first mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com