Stainless steel surface stud welding device

A stud welding and stainless steel technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of high error rate, long time for sample production, low efficiency, etc., and achieve the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

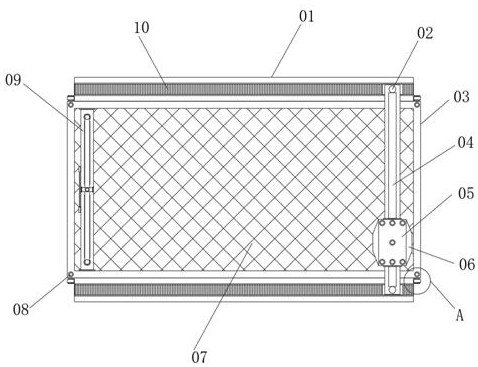

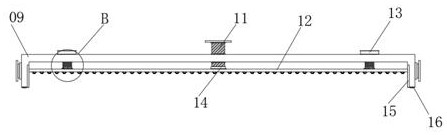

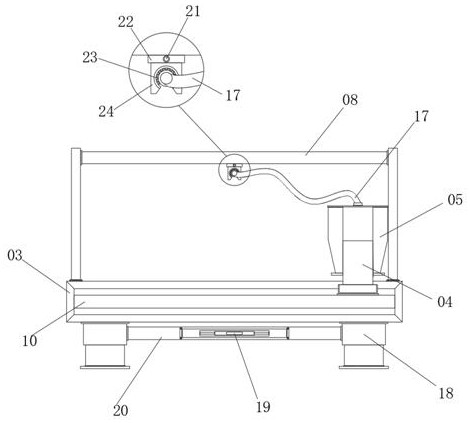

[0031] see figure 1 : Including the working board 03, the top of the working board 03 is provided with a square groove, and the hollow board 07 is fixedly connected, the top and the bottom of the working board 03 are fixedly connected with the baffle 01, and the baffle 01 is an "L" shaped structure, The inner side of the horizontal wall of the baffle plate 01 is provided with a bar-shaped groove and a slide rail 10 is installed. The inner side of the slide rail 10 is provided with a positioning stud 02. The bottom of the positioning stud 02 is square and is slidably connected with the inside of the slide rail 10. The outer side of the cylinder of the positioning stud 02 is sleeved with a sliding rod 04, the outer side of the sliding rod 04 is slidably connected with a welding device 05, the outer side of the welding device 05 is provided with a control board 06, and the top of the welding device 05 is provided with a circular through hole And it is fixedly connected with a del...

Embodiment 2

[0033] see Figure 4 : the outside of the limiting ring 26 is equidistantly provided with several bar-shaped grooves, and bolts 27 are installed at the bar-shaped grooves, and threaded through holes are equidistantly provided at the four peripheral corners of the top of the connecting frame 25, and the threaded through holes A bolt 30 is threadedly connected at the place, and the bottom of the working plate 03 penetrates through the bolt 30 .

Embodiment 3

[0035] see Figure 5 : the left and right sides of the baffle plate 01 are fixedly connected with an extension block 32, and the block body of the extension block 32 is provided with a threaded through hole, and the threaded through hole is threaded with a threaded post 31, and one end of the threaded post 31 is connected to the working The outside of the plate 03 is screwed together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com