Loose material compact molding friction wear test device

A friction and wear test, loose material technology, used in teaching models, grain processing, die extrusion granulation, etc. To achieve the effect of reuse, economic cost saving, and controllable moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

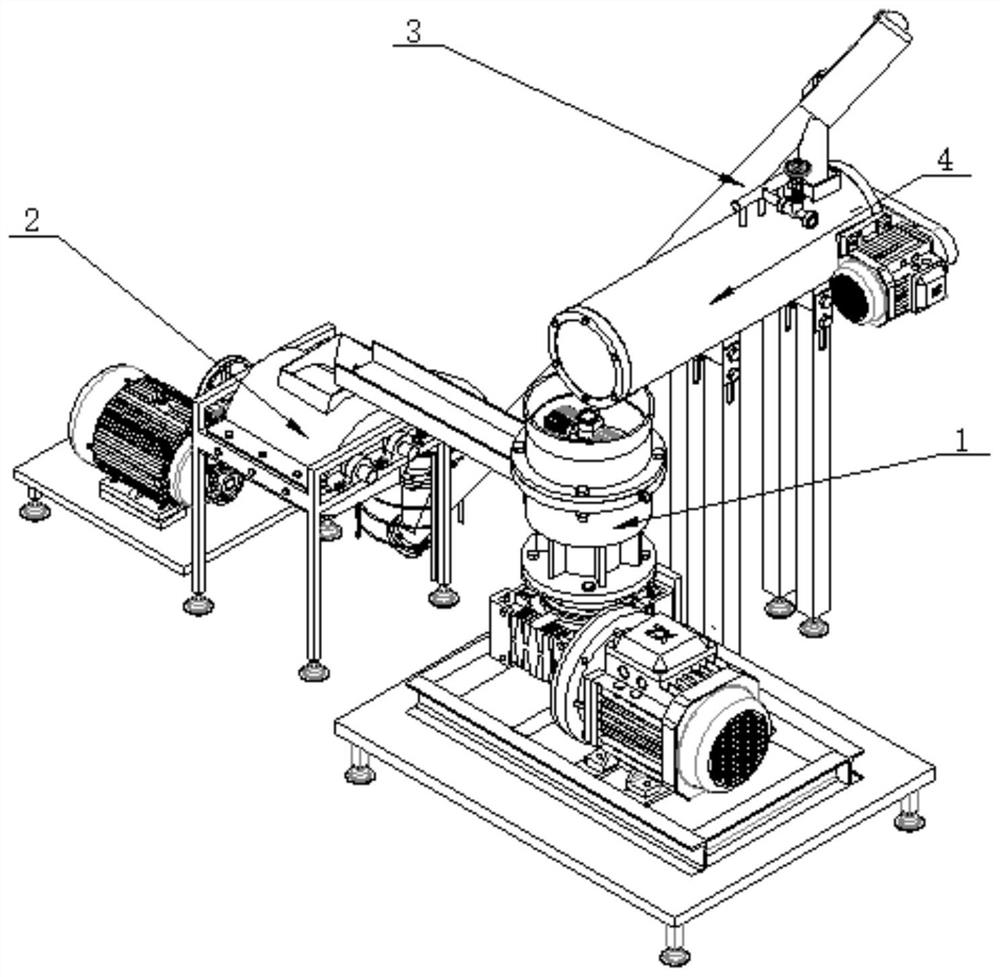

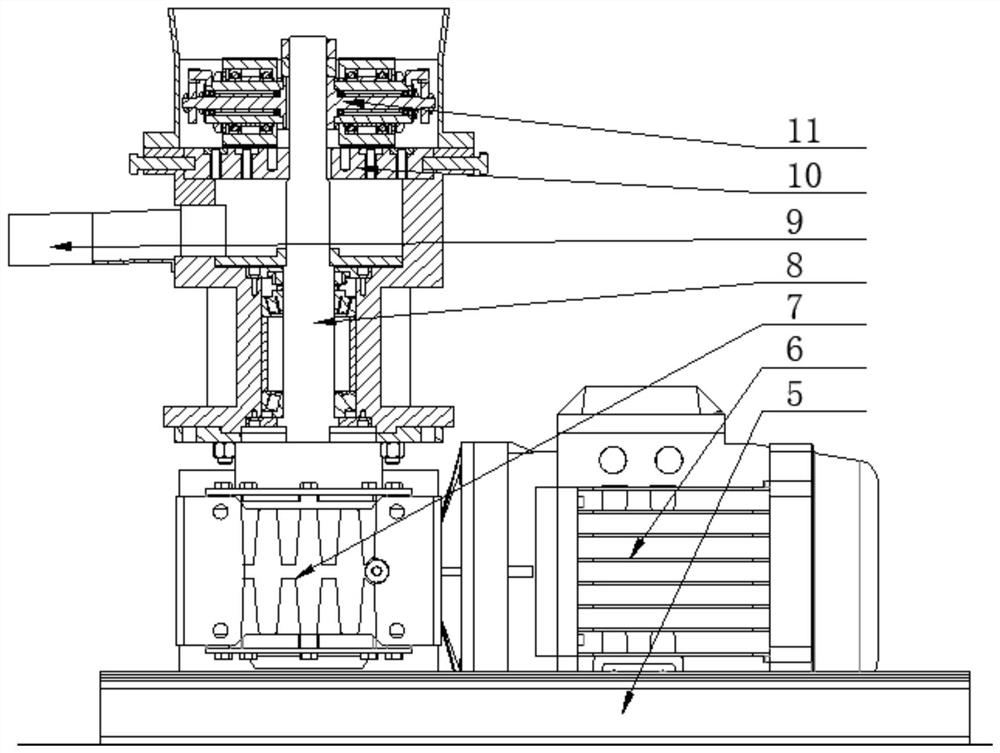

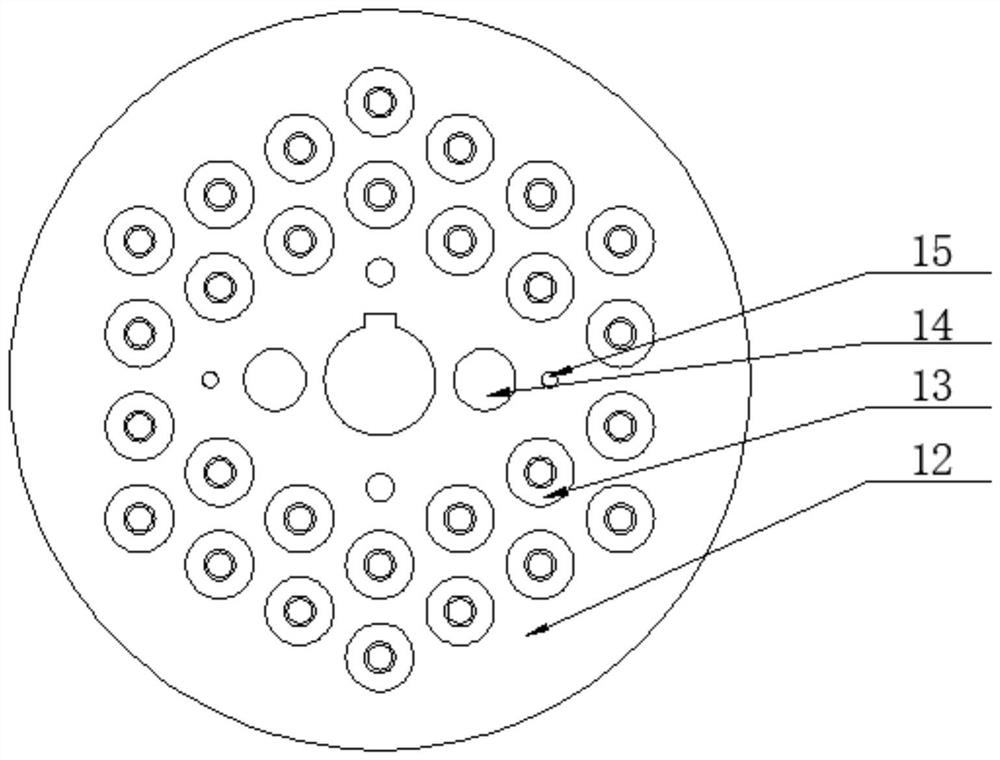

[0022] combine Figure 1~Figure 10 , a friction and wear test device for compact molding of loose materials, including a molding unit 1, a crushing unit 2, a conveying unit 3 and a physical property control unit 4, the molding unit 1 compresses and shapes the loose materials and sends them into the crushing unit 2 through a discharge channel 9 At the feed port, the crushing unit 2 crushes the molding material into granular materials, and transports the granular materials to the material inlet of the physical property control unit 4 through the conveying unit 3. The temperature and humidity sensor in the physical property control unit 4 monitors the moisture and temperature of the granular materials. When the moisture And when the temperature does not match the preset value, the water addition and heating operations are performed. After the operation is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com