Polyurethane arc-shaped screen

A polyurethane and arc-shaped technology, which is applied in the field of polyurethane arc-shaped screens, can solve the problems of short service life and low screening efficiency of arc-shaped screens, achieve good reinforcement effects, and reduce the probability of hair hanging and blocking holes , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

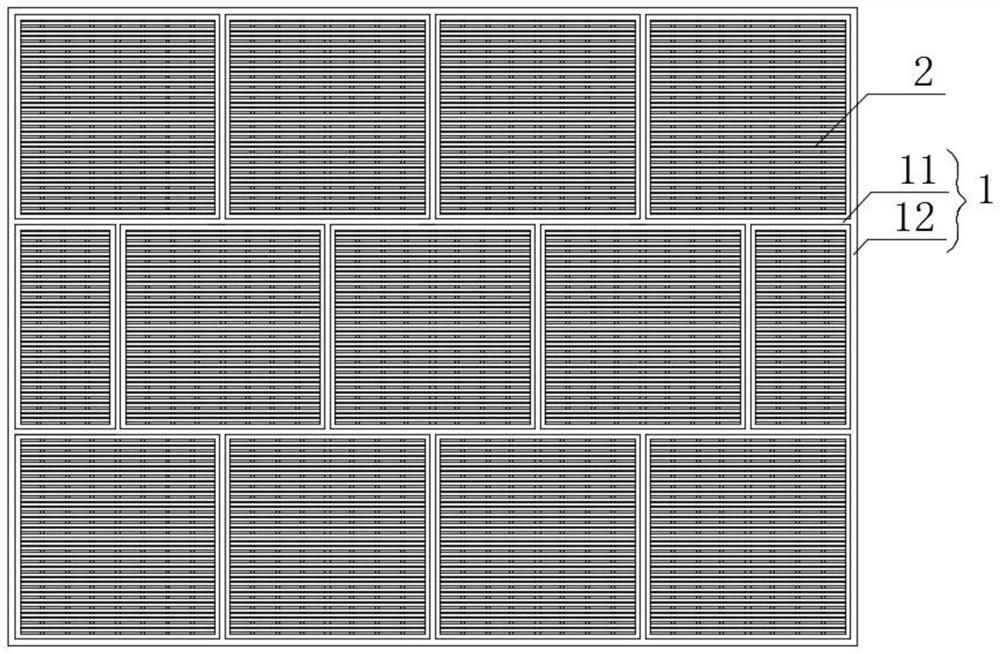

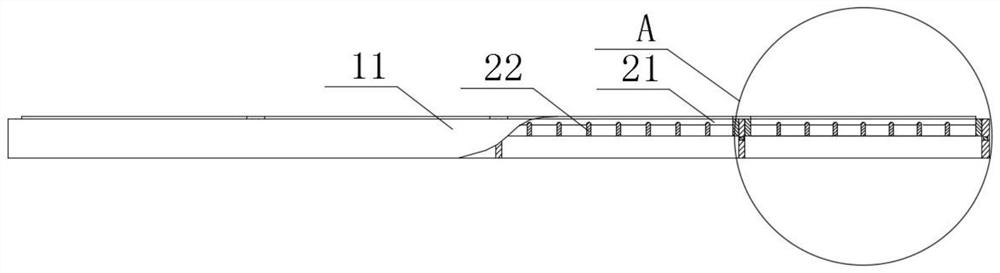

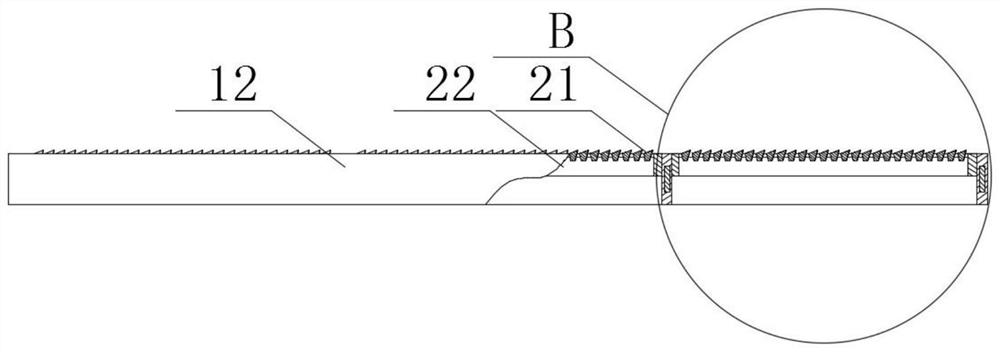

[0034] Example 1, see Figure 1-8 , the present invention provides a technical solution, a polyurethane arc screen, including a support frame 1 and a screen 2, the support frame 1 includes a transverse support bar 11 and a longitudinal support bar 12, the transverse support bar 11 and the longitudinal support bar 12 forms a grid-like structure, the transverse support bar 11 is inlaid with a transverse frame 111 in the axial direction, and the transverse frame 111 is a vertical flat steel; the longitudinal support bar 12 is inlaid with a longitudinal frame 121 in the axial direction, and the longitudinal frame 121 is flat. Flat steel; screen sheet 2 includes frame 23 and several transverse screen bars 21 and several longitudinal screen bars 22 connected to the inner edge of frame 23, and both ends of longitudinal screen bars 22 are vertically fixed and connected to the front wall of the inner cavity of frame 23 respectively. and the rear wall, the upper surface of the longitudi...

Embodiment 2

[0035] Example 2, see Figure 1-8, the present invention provides a technical solution, a polyurethane arc screen, including a support frame 1 and a screen 2, the support frame 1 includes a transverse support bar 11 and a longitudinal support bar 12, the transverse support bar 11 and the longitudinal support bar 12 forms a grid-like structure, the transverse support bar 11 is inlaid with a transverse frame 111 in the axial direction, and the transverse frame 111 is a vertical flat steel; the longitudinal support bar 12 is inlaid with a longitudinal frame 121 in the axial direction, and the longitudinal frame 121 is flat. Flat steel; screen sheet 2 includes frame 23 and several transverse screen bars 21 and several longitudinal screen bars 22 connected to the inner edge of frame 23, and both ends of longitudinal screen bars 22 are vertically fixed and connected to the front wall of the inner cavity of frame 23 respectively. and the rear wall, the upper surface of the longitudin...

Embodiment 3

[0036] Example 3, see Figure 1-8 , the present invention provides a technical solution, a polyurethane arc screen, including a support frame 1 and a screen 2, the support frame 1 includes a transverse support bar 11 and a longitudinal support bar 12, the transverse support bar 11 and the longitudinal support bar 12 forms a grid-like structure, the transverse support bar 11 is inlaid with a transverse frame 111 in the axial direction, and the transverse frame 111 is a vertical flat steel; the longitudinal support bar 12 is inlaid with a longitudinal frame 121 in the axial direction, and the longitudinal frame 121 is flat. Flat steel; screen sheet 2 includes frame 23 and several transverse screen bars 21 and several longitudinal screen bars 22 connected to the inner edge of frame 23, and both ends of longitudinal screen bars 22 are vertically fixed and connected to the front wall of the inner cavity of frame 23 respectively. and the rear wall, the upper surface of the longitudi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com