Preparation method of throat-relieving tea-flavored spice and heated cigarette

A fragrance-type and throat-relieving technology, which is applied in the field of flavors and fragrances, can solve problems such as difficulty in releasing fragrances, inappropriate pyrolysis temperature, and poor thermal stability, etc., to achieve good fragrance release, improve thermal stability, and avoid Dissipated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

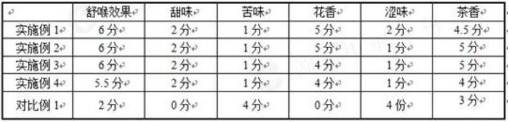

Examples

Embodiment 1

[0031] S1. Place the fresh tea leaves in the sun to dry naturally for 12 hours, then crush to obtain 50g of tea powder, add 600ml of 80% ethanol, raise the temperature to above 80°C, and extract under reflux for 2 hours. After heating and refluxing, the mixture was cooled to room temperature, filtered to remove solid insolubles, the temperature was raised to 80°C, and the liquid was concentrated under reduced pressure until the quality no longer decreased, and the obtained tea extract was refrigerated at about 4°C for later use.

[0032] S2. Place the fresh honeysuckle in the sun for 12 hours of natural drying. After drying, extract 20 g of it with 40% ethanol solution, add hydrochloric acid to adjust the pH value to 6, heat under reflux in a water bath at 80 °C, and filter while hot. Add 40% ethanol to the filter residue again to repeat the extraction, combine the filtrates, and concentrate the filtrate under reduced pressure until the quality is no longer reduced to obtain ho...

Embodiment 2

[0036] S1. Place the fresh tea leaves in the sun to dry naturally for 12 hours, then crush to obtain 50g of tea powder, add 600ml of 80% ethanol, raise the temperature to above 80°C, and extract under reflux for 2 hours. After heating and refluxing, the mixture was cooled to room temperature, filtered to remove solid insolubles, the temperature was raised to 80°C, and the liquid was concentrated under reduced pressure until the quality no longer decreased, and the obtained tea extract was refrigerated at about 4°C for later use.

[0037]S2. Place the fresh honeysuckle in the sun for 12 hours of natural drying. After drying, extract 20 g of it with a 40% ethanol solution, add acetic acid to adjust the pH value to 6, heat under reflux in a water bath at 80 °C, and filter while hot. 40% ethanol was added to the filter residue again to repeat the extraction, the filtrates were combined, and the filtrate was concentrated under reduced pressure until the quality no longer decreased t...

Embodiment 3

[0041] S1. Place the fresh tea leaves in the sun to dry naturally for 12 hours, then crush to obtain 50g of tea powder, add 600ml of 80% ethanol, raise the temperature to above 80°C, and extract under reflux for 2 hours. After heating and refluxing, the mixture was cooled to room temperature, filtered to remove solid insolubles, the temperature was raised to 80°C, and the liquid was concentrated under reduced pressure until the quality no longer decreased, and the obtained tea extract was refrigerated at about 4°C for later use.

[0042] S2. Place the fresh honeysuckle in the sun for 12 hours of natural drying. After drying, extract 20 g of it with 40% ethanol solution, add hydrochloric acid to adjust the pH value to 6, heat under reflux in a water bath at 80 °C, and filter while hot. 40% ethanol was added to the filter residue again to repeat the extraction, the filtrates were combined, and the filtrate was concentrated under reduced pressure until the quality no longer decrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com