A test device and test method for simulating tire burst

The technology of a test device and test method is applied in the direction of automobile tire test, measuring device, vehicle test, etc. It can solve the problem that the process of simulating a tire blowout is not realistic enough, and achieves convenient operation, fast pressure release speed and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

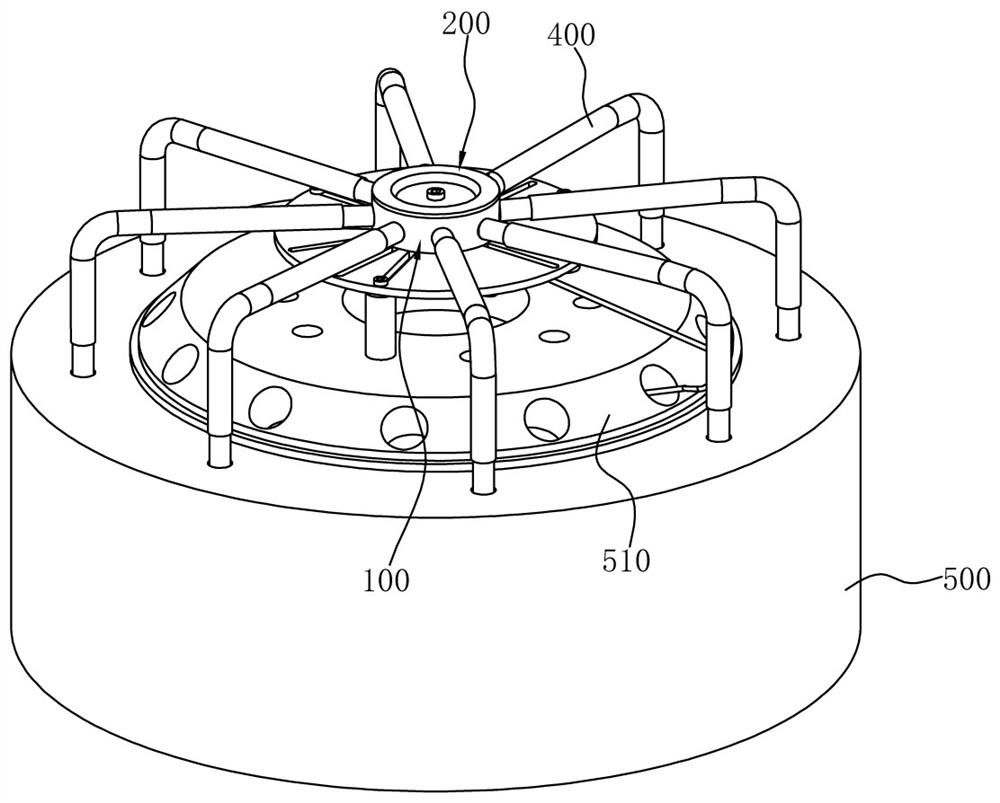

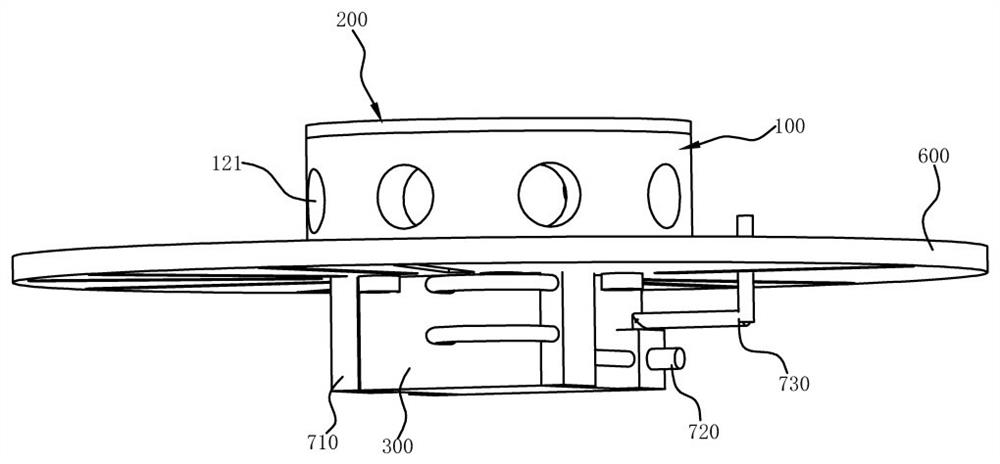

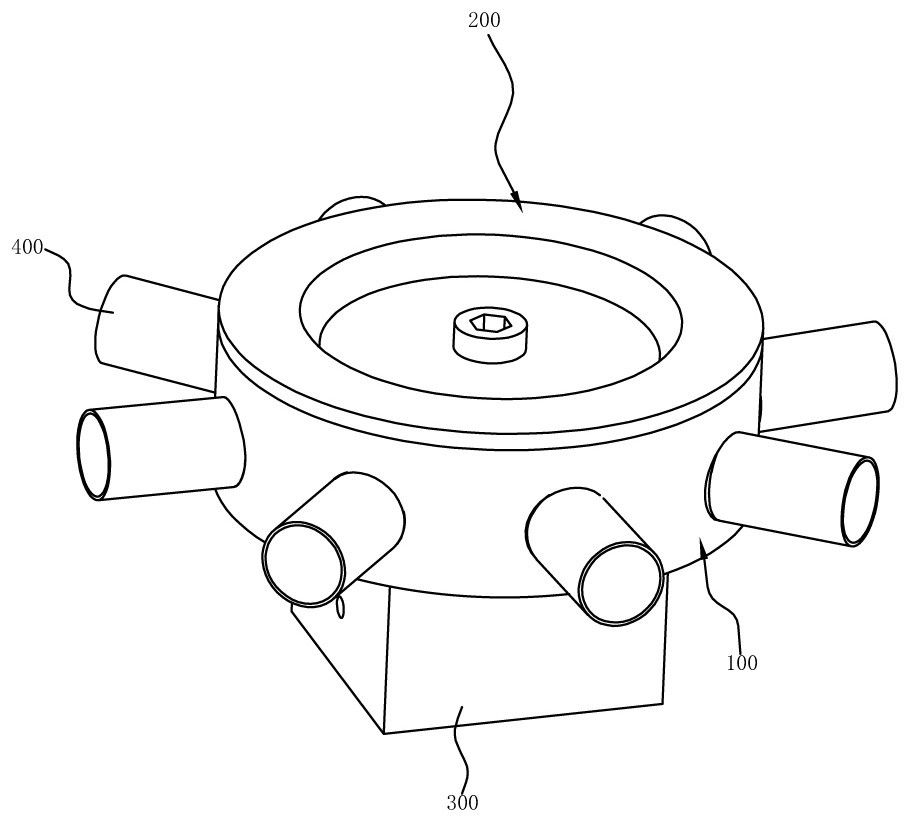

[0054] Please refer to Figure 1-Figure 8 , the invention discloses a test device for simulating tire bursting, comprising:

[0055] Cylinder 100, the cylinder 100 includes a base 110 and a first side ring 120, the base 110 is fixedly connected to the lower end of the first side ring 120, and the first side ring 120 is provided with a plurality of first Through hole 121;

[0056] The cover body 200 is arranged above the cylinder body 100, and a pressure holding space is provided between the cover body 200 and the cylinder body 100, and the cover body 200 can move up and down relative to the cylinder body 100 to sealing or opening the pressure holding space; the pressure holding space communicates with a plurality of firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com