Pile body variable concrete strength grade cast-in-place pile and strength grade determining method thereof

A technology of concrete strength and determination method, which is applied in sheet pile wall, special data processing application, geometric CAD, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

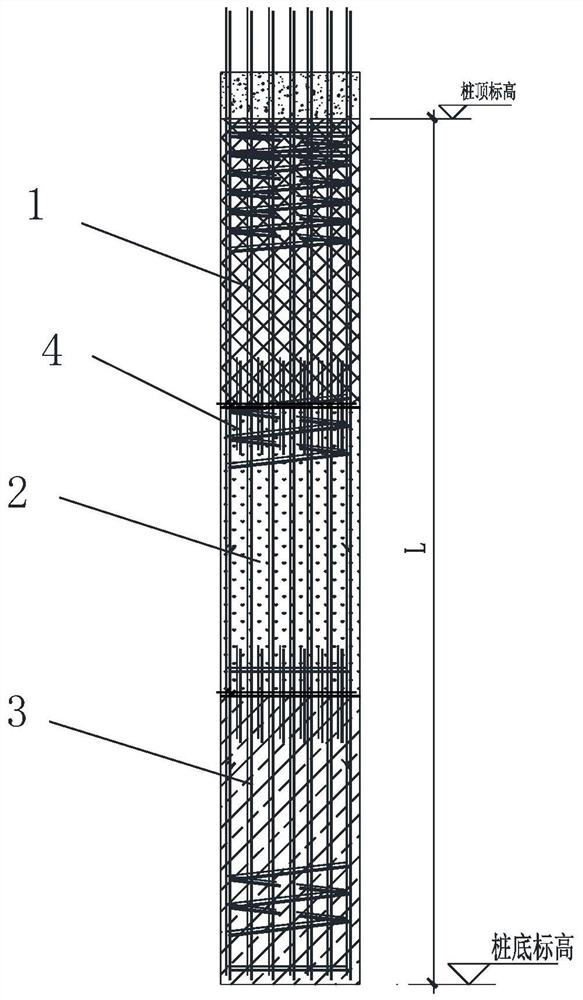

[0098] In this embodiment, the pile length is 50m and the pile diameter is 800mm pile body variable concrete strength grade cast-in-situ pile as an example, see 1, the concrete strength grade determination method of concrete pile body variable concrete strength grade cast-in-place pile is realized by the following steps:

[0099] 1) Collect the soil layer parameters of the construction area according to the common method as shown in the following table:

[0100]

[0101]

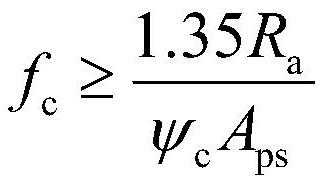

[0102] 2) According to the total length of the pile, determine the number of sections of the pile body z=3, and the length of each section is 16.7m; 3) Calculate the concrete compressive strength at each section of the cast-in-situ pile by the following formula;

[0103]

[0104] (3.1) Calculated from the top of the pile, the concrete strength grade of the first pile body 1:

[0105]

[0106] Calculated from the top of the pile, the concrete strength grade of 1 / 3 of the long pile body adopts C45....

Embodiment 2

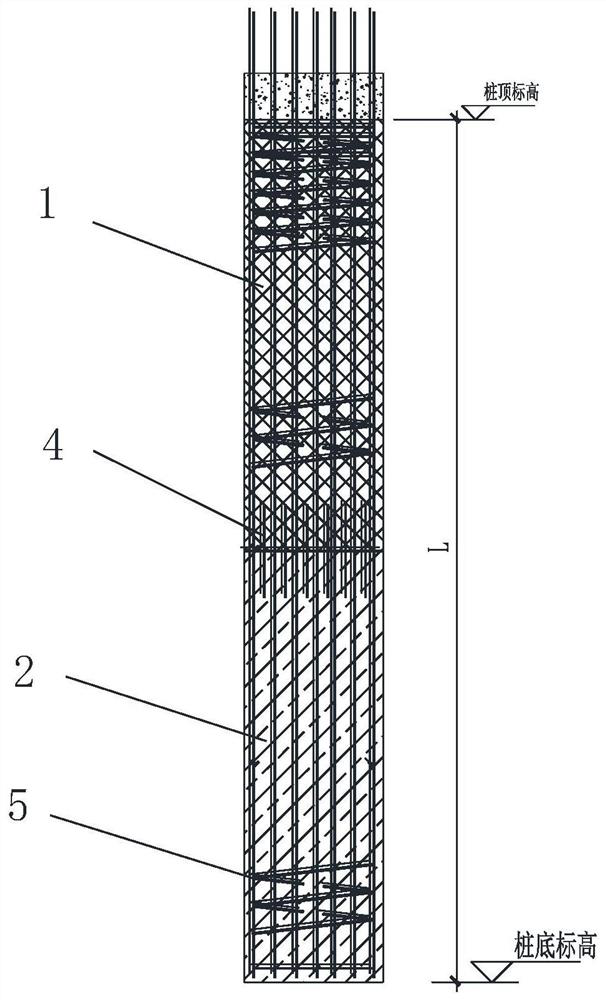

[0115] In this embodiment, the pile length is 30m, and the pile diameter is 600mm. The pile body becomes the concrete strength grade cast-in-situ pile as an example. Refer to 2. The concrete strength grade determination method of the pile body becomes the concrete strength grade cast-in-place pile, which is realized by the following steps:

[0116] 1) Collect the soil layer parameters of the construction area according to the common method as shown in the following table:

[0117]

[0118]

[0119] 2) According to the total length of the pile, the number of sections of the pile body z=2 is determined, and the length of each section is 15m;

[0120] 3) Calculate the concrete compressive strength at each section of the cast-in-place pile by the following formula;

[0121]

[0122] (3.1) Calculated from the top of the pile, the concrete strength grade of the first pile body 1:

[0123]

[0124] Calculated from the top of the pile, the concrete strength grade of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com