TS-29 hydrophilic polyurethane grouting material and preparation process thereof

A hydrophilic polyurethane, TS-29 technology, applied in the field of grouting plugging, can solve the problem of unsatisfactory secondary water plugging effect, and achieve the effect of good market prospect, good adhesion and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

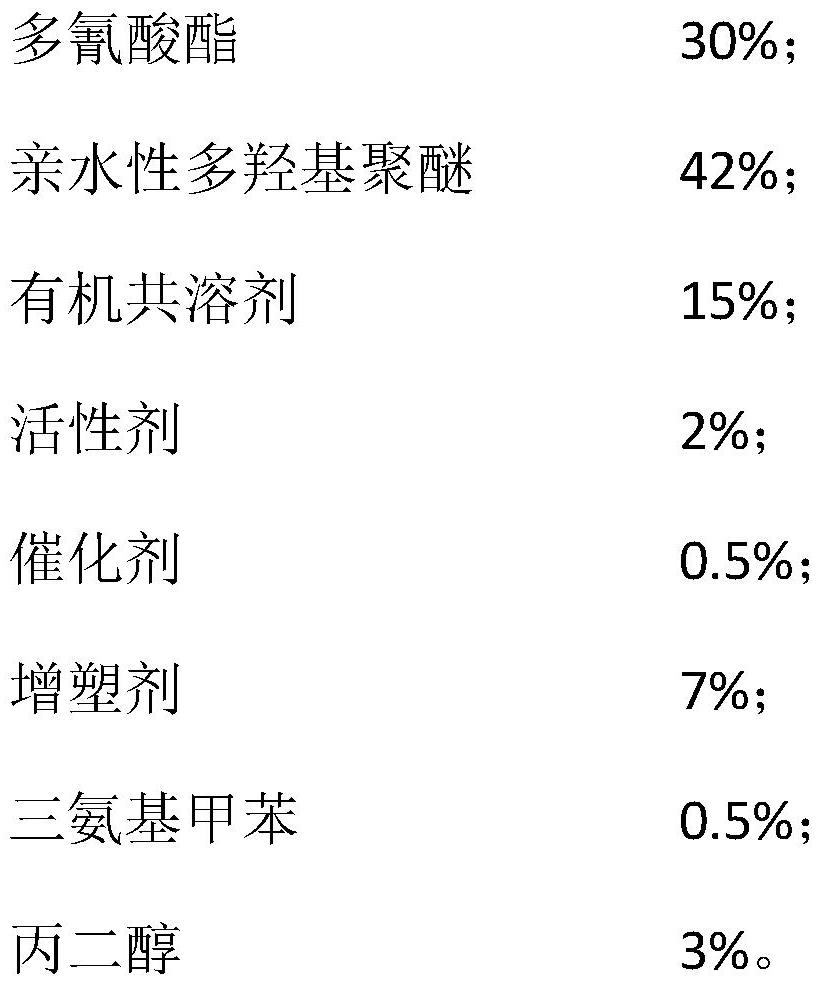

Image

Examples

Embodiment 1

[0041] In this example, the TS-29 hydrophilic polyurethane grouting material consists of 25% polycyanate, 50% hydrophilic polyhydroxy polyether, 15% organic co-solvent, 1% activator , 0.5% catalyst, 5% plasticizer, 0.5% triaminotoluene and 3% propylene glycol.

[0042] The technological process for preparing TS-29 hydrophilic polyurethane grouting material with the above ratio of raw materials is as follows:

[0043] 1) Put the hydrophilic polyhydroxy polyether into the reaction kettle, raise the temperature to 95°C, stir, vacuumize to 0.1MPa for dehydration and degassing for 2.5 hours, and cool down to 53°C;

[0044] 2) Add polycyanate after step 1), react at a reaction temperature of 85°C for 2.5 hours, and cool down to 55°C;

[0045] 3) After step 2), add organic solvent (preferably adopt acetone), active agent (preferably adopt water-soluble silicone oil), catalyst (preferably adopt methylmorpholine), plasticizer (preferably adopt diethyl phthalate ), triaminotoluene and...

Embodiment 2

[0047] In this example, the TS-29 hydrophilic polyurethane grouting material consists of 50% polycyanate, 25% hydrophilic polyhydroxy polyether, 10% organic co-solvent, and 3% active agent by weight percentage. , 0.2% catalyst, 9% plasticizer, 0.7% triaminotoluene and 2.1% propylene glycol.

[0048] The technological process for preparing TS-29 hydrophilic polyurethane grouting material with the above ratio of raw materials is as follows:

[0049] 1) Put the hydrophilic polyhydroxy polyether into the reaction kettle, raise the temperature to 105°C, stir, evacuate to 0.2MPa for dehydration and degassing for 3 hours, and cool down to 50°C;

[0050] 2) Add polycyanate after step 1), and react for 3 hours at a reaction temperature of 75°C,

[0051] Cool down to 45°C;

[0052] 3) After step 2), add organic solvent (preferably adopt acetone), active agent (preferably adopt water-soluble silicone oil), catalyst (preferably adopt methylmorpholine), plasticizer (preferably adopt diet...

Embodiment 3

[0054] In this embodiment, the TS-29 hydrophilic polyurethane grouting material consists of 38% polycyanate, 30% hydrophilic polyhydroxy polyether, 20% organic co-solvent, and 1.8% active agent by weight percentage. , 0.8% catalyst, 8.1% plasticizer, 0.3% triaminotoluene and 1% propylene glycol.

[0055] The technological process for preparing TS-29 hydrophilic polyurethane grouting material with the above ratio of raw materials is as follows:

[0056] 1) Put the hydrophilic polyhydroxy polyether into the reaction kettle, raise the temperature to 100°C, stir, evacuate to 0.15MPa for dehydration and degassing for 2 hours and 50 minutes, and cool down to 51°C;

[0057] 2) Add polycyanate after step 1), react at a reaction temperature of 80°C for 2 hours and 40 minutes, and cool down to 50°C;

[0058] 3) After step 2), add organic solvent (preferably adopt acetone), active agent (preferably adopt water-soluble silicone oil), catalyst (preferably adopt methylmorpholine), plasticize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com