Silkworm cocoon extraction device for sericulture

A technology for removing cocoons and cocoons, which is applied in the fields of animal husbandry, transportation and packaging, conveyor objects, etc., can solve the problems of affecting the health of workers' hands, low efficiency, slow cocoon removal, etc., to improve efficiency and reduce time. Cost, effect of protecting hand health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

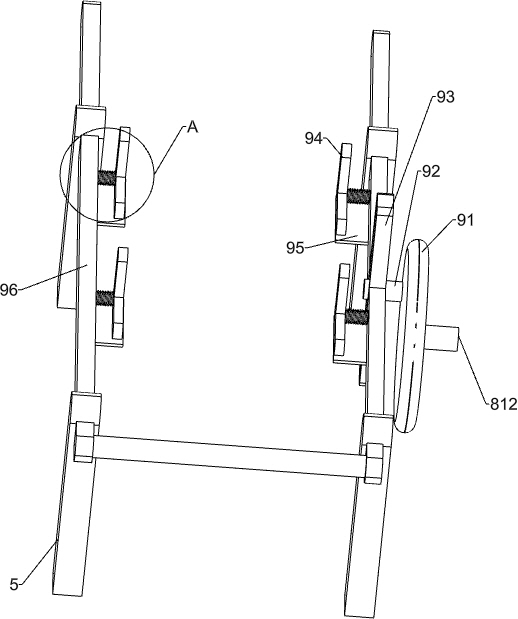

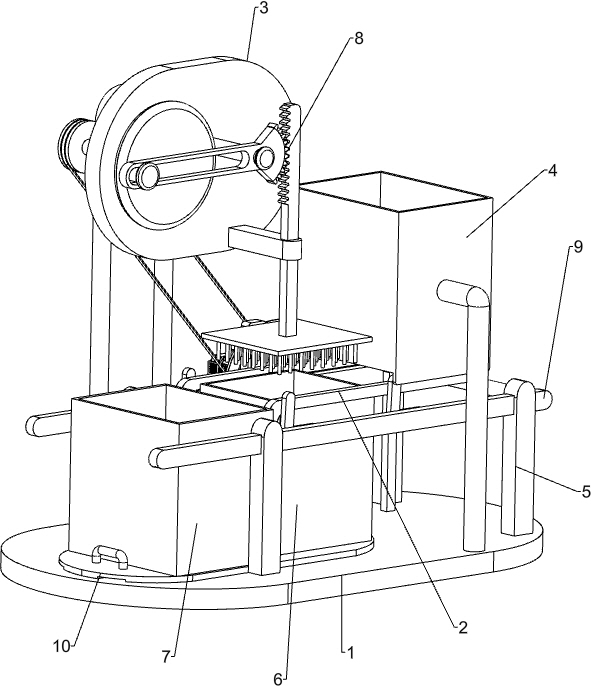

[0044] A device for taking out silkworm cocoons for sericulture, such as figure 1 As shown, it includes a base 1, a support frame 2, a mounting frame 3, a discharging frame 4, a first sliding sleeve 5, a receiving frame 6, a wooden receiving frame 7, a retrieving mechanism 8, a pushing mechanism 9 and a slide plate 10, Both the front and rear parts of the upper side of the base 1 are connected with the support frame 2, the upper side and the rear part of the base 1 are connected with the installation frame 3, the upper right part of the base 1 is connected with the discharge frame 4, and the upper side of the base 1 is connected with the first The sliding sleeve 5 is connected with the feeding mechanism 8 on the front side of the mounting frame 3, the pushing mechanism 9 is slidably connected between the first sliding sleeve 5, the upper left part of the base 1 is slidably connected with the slide plate 10, and the upper left part of the slide plate 10 is The wooden frame 7 is...

Embodiment 2

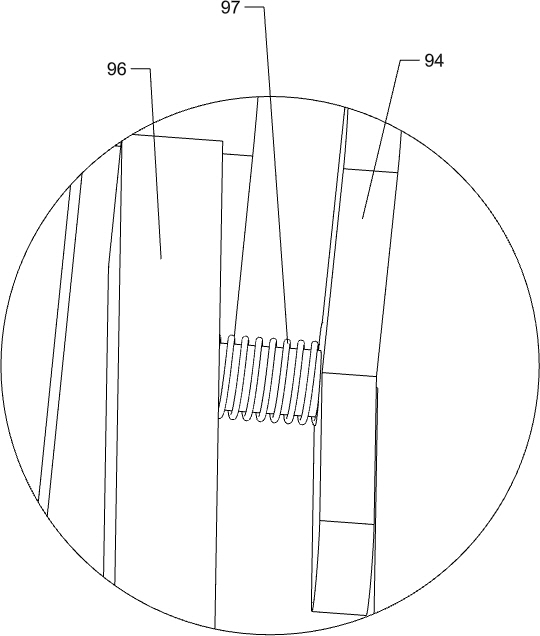

[0047] On the basis of Example 1, such as figure 2 As shown, the retrieving mechanism 8 includes a mounting seat 81, a motor 82, a transmission assembly 83, a first rotating shaft 84, a first disk 85, a first bump 86, a gear rod 87, a rotating column 88, a rack bar 89, The second sliding sleeve 810, the pushing block 811 and the second rotating shaft 812, the upper rear part of the base 1 is connected with a mounting seat 81, the mounting seat 81 is located on the right side of the mounting frame 3, the top side of the mounting seat 81 is connected with a motor 82, and the mounting frame 3 The left part is connected with the first rotating shaft 84 in a rotating manner, the output shaft of the motor 82 is connected with the second rotating shaft 812, the transmission assembly 83 is wound between the second rotating shaft 812 and the first rotating shaft 84, and the front end of the first rotating shaft 84 is connected with the second rotating shaft A disc 85, the eccentric po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com