A polishing process for the channel opening of the back plate in a molybdenum-niobium target assembly

A process and target material technology, which is applied in the field of polishing, can solve the problems of unstable polishing and reduced service life of water outlets, and achieve the effects of improved one-time pass rate, extended service life and stable polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

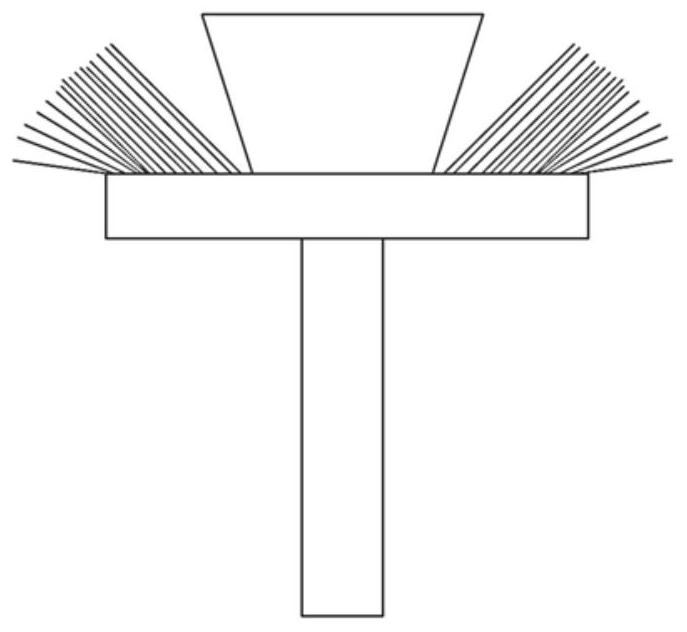

[0039] This embodiment provides a polishing process for the water channel opening of the back plate in the molybdenum-niobium target assembly, the polishing process includes using an umbrella-shaped polishing brush ( figure 1 ) for polishing;

[0040] The rotation mode of polishing brush in described polishing is clockwise;

[0041] The rotating speed of polishing brush in described polishing is 0.9m / s;

[0042] The polishing time is 17s, and the polishing depth is 0.04mm;

[0043] The umbrella-shaped polishing brush comprises a rounded truncated polishing surface and a belt-shaped polishing surface distributed around it, and the polishing wire length of the polishing brush is 20mm;

[0044] The included angle between the rounded truncated side and the horizontal plane is 85°, and the diameter of the bottom surface of the rounded truncated polished surface is 1.5cm;

[0045] The width of the strip-shaped polishing surface is 0.4mm;

[0046] The polishing wires in the belt-sh...

Embodiment 2

[0049] This embodiment provides a polishing process for the water channel opening of the back plate in the molybdenum-niobium target assembly, the polishing process includes polishing the water channel opening of the back plate in the molybdenum-niobium target assembly with an umbrella-shaped polishing brush;

[0050] The rotation mode of polishing brush in described polishing is clockwise;

[0051] The rotating speed of the polishing brush in the polishing in the polishing is 0.8m / s;

[0052] The polishing time is 20s, and the polishing depth is 0.35mm;

[0053] The umbrella-shaped polishing brush comprises a rounded truncated polishing surface and a belt-shaped polishing surface distributed around it, and the length of the polishing wire of the polishing brush is 15mm;

[0054] The included angle between the rounded truncated side and the horizontal plane is 88°, and the diameter of the bottom surface of the rounded truncated polished surface is 3cm;

[0055] The width of ...

Embodiment 3

[0059] This embodiment provides a polishing process for the water channel opening of the back plate in the molybdenum-niobium target assembly, the polishing process includes polishing the water channel opening of the back plate in the molybdenum-niobium target assembly with an umbrella-shaped polishing brush;

[0060] The rotation mode of the polishing brush in the polishing is clockwise;

[0061] The rotating speed of the polishing brush in the polishing in the polishing is 1m / s;

[0062] The polishing time is 15s, and the polishing depth is 0.045mm;

[0063] The umbrella-shaped polishing brush comprises a rounded truncated polishing surface and a belt-shaped polishing surface distributed around it, and the length of the polishing wire of the polishing brush is 17mm;

[0064] The included angle between the rounded truncated side and the horizontal plane is 86°, and the diameter of the bottom surface of the rounded truncated polished surface is 1.8cm;

[0065] The width of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com