Clamp switching device

A technology for switching devices and fixtures, which is applied in auxiliary devices, manufacturing tools, transportation and packaging, etc., and can solve the problems of large positioning structure, complex structure, and poor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

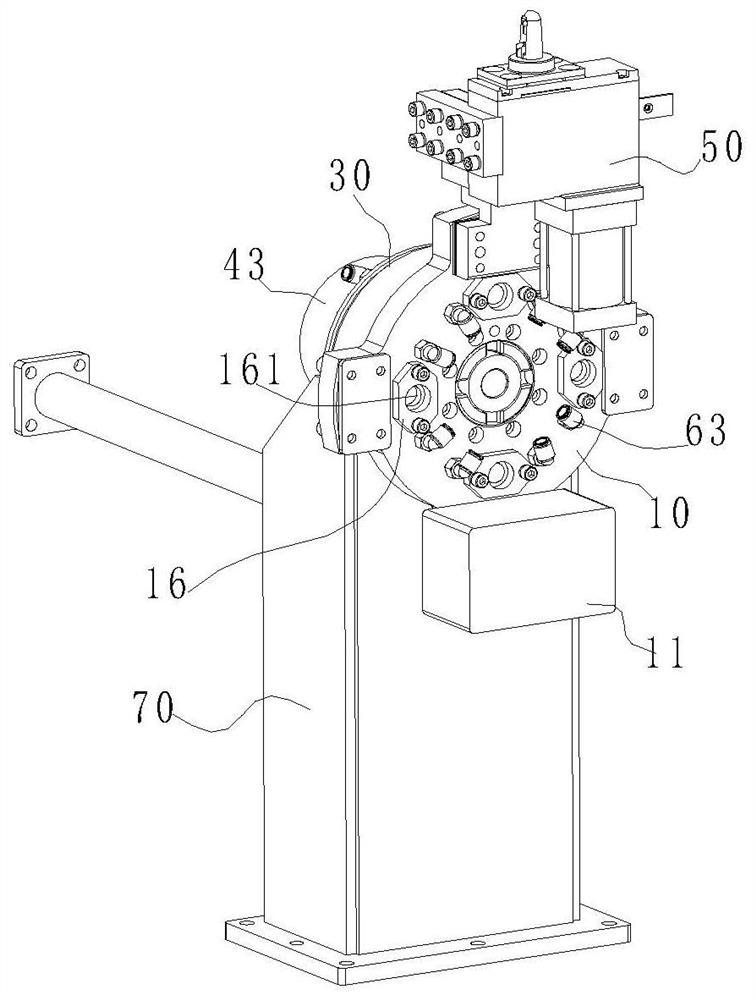

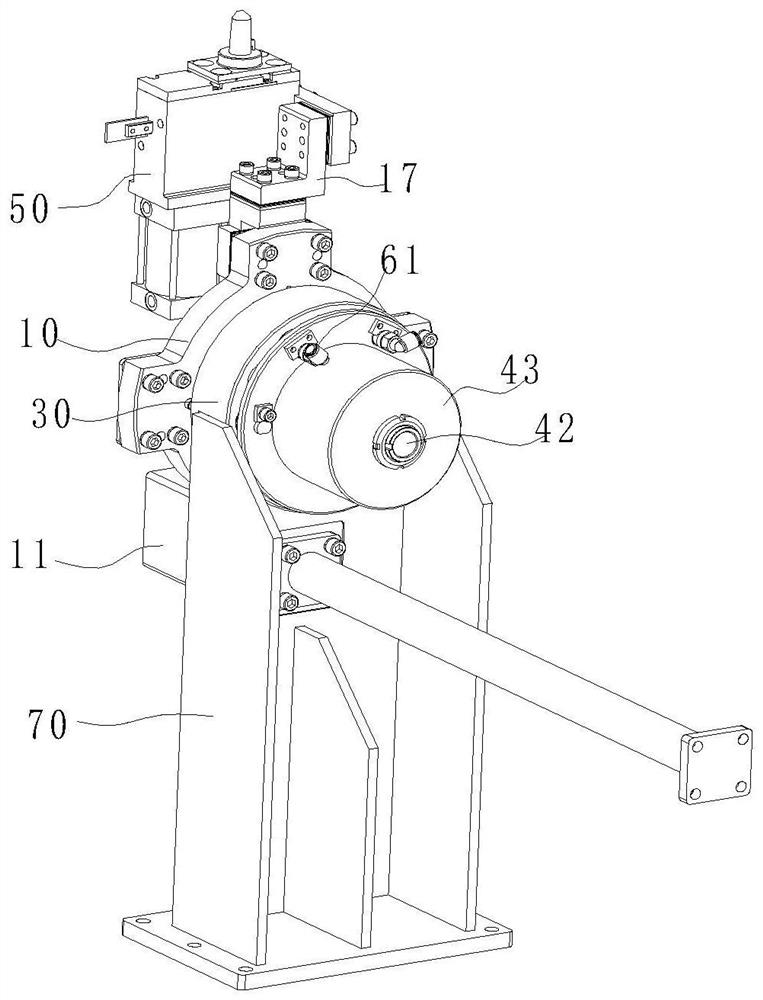

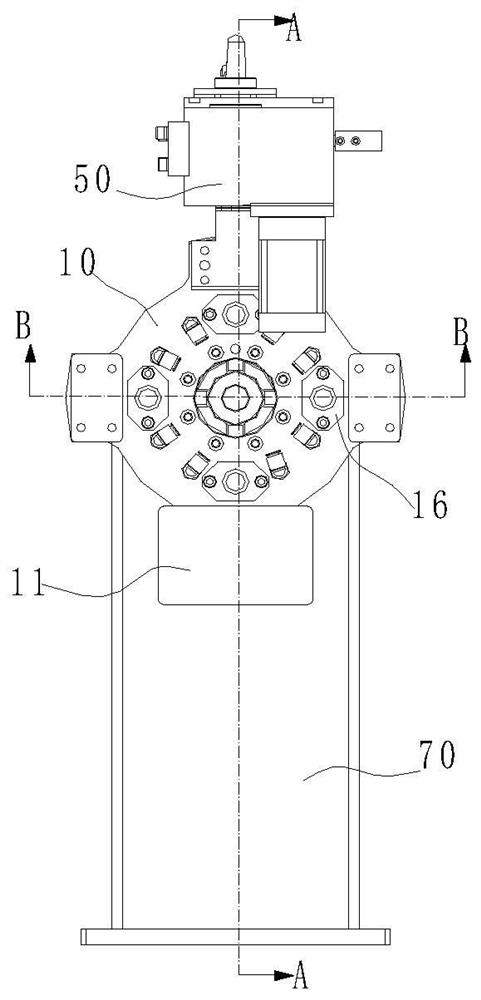

[0016] Combine below Figure 1-Figure 11 The present invention is discussed in further detail.

[0017] A clamp switching device, comprising a mounting plate 10, the clamping mechanism 50 for clamping the vehicle body is arranged at intervals on the peripheral surface of the mounting plate 10, the mounting plate 10 is coaxially fixed with a rotating shaft 21, and the rotating shaft 21 is rotated and arranged on a fixed On the seat 30 , a positioning pin 41 is also arranged on the fixed seat 30 , and when the positioning pin 41 slides along its own axial direction, it is inserted into and locked with the positioning hole 12 provided on the mounting plate 10 or separated and unlocked. The axial direction of the locating pin 41 and the axial direction of the rotating shaft 21 may be parallel or non-parallel, as long as the locking and unlocking of the mounting disk 10 can be realized, the axial direction of the locating pin 41 is preferably parallel to the rotating shaft 21. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com