A kind of indoor simulated asphalt mixture aging method

A technology of asphalt mixture and mixture, applied in the direction of analysis materials, instruments, measuring devices, etc., can solve the problems of asphalt mixture performance aging and pavement performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] Step 1, sample preparation: According to the required mineral material gradation and asphalt dosage, the asphalt mixture is prepared according to the method specified in the road engineering asphalt and asphalt mixture test regulations.

[0019] Step 2, short-term aging: The asphalt mixture obtained in step 1 is subjected to short-term aging according to the method specified in the road engineering asphalt and asphalt mixture test regulations.

[0020] Step 3: For the short-term aging asphalt mixture obtained in step 2, make a standard Marshall test piece according to the method specified in the road engineering asphalt and asphalt mixture test regulations, and then cool and remove the film. The size of the standard Marshall test piece is 101.6mm×63.5mm, the mass is 1200g, and the oil-stone ratio is 4.6%.

[0021] Step 4, place the pattern obtained in step 3 on the pattern rack and send it into an oven at 82°C, and heat continuously for 59.5h under forced ventilation. ...

specific Embodiment 2

[0028] Step 1, sample preparation: According to the required mineral material gradation and asphalt dosage, the asphalt mixture is prepared according to the method specified in the road engineering asphalt and asphalt mixture test regulations.

[0029] Step 2, short-term aging: The asphalt mixture obtained in step 1 is subjected to short-term aging according to the method specified in the road engineering asphalt and asphalt mixture test regulations.

[0030] Step 3: For the short-term aging asphalt mixture obtained in step 2, make a standard Marshall test piece according to the method specified in the road engineering asphalt and asphalt mixture test regulations, and then cool and remove the film. The size of the standard Marshall test piece is 101.6mm×63.5mm, the mass is 1200g, and the oil-stone ratio is 4.6%.

[0031] Step 4, place the pattern obtained in step 3 on the pattern rack and send it into an oven at 82°C, and heat continuously for 60.5h under forced ventilation. ...

specific Embodiment 3

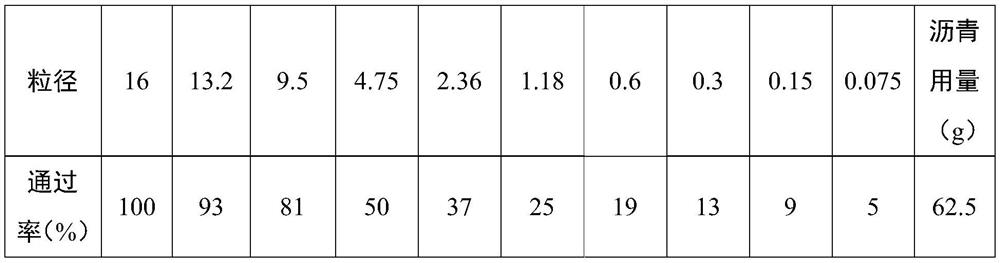

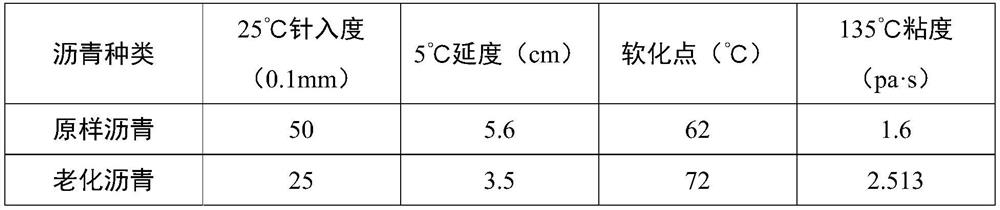

[0038] Step 1, sample preparation: According to the required mineral material gradation and asphalt dosage, the asphalt mixture was prepared according to the method specified in the road engineering asphalt and asphalt mixture test regulations. The mineral gradation and asphalt dosage are shown in Table 1.

[0039] Table 1: Index values measured by each extracted bitumen in the examples

[0040]

[0041] Step 2, short-term aging: The asphalt mixture obtained in step 1 is subjected to short-term aging according to the method specified in the road engineering asphalt and asphalt mixture test regulations.

[0042] Step 3: For the short-term aging asphalt mixture obtained in step 2, make a standard Marshall test piece according to the method specified in the road engineering asphalt and asphalt mixture test regulations, and then cool and remove the film. The size of the standard Marshall test piece is 101.6mm×63.5mm, the mass is 1200g, and the oil-stone ratio is 4.6%.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com