Assembly type heat exchange station

A heat exchange station, assembled technology, applied in the field of heat exchange stations, can solve the problems of many equipment interfaces, low degree of equipment debugging integration, mutual buck-passing and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 pic 1, no. 1 4、 no. 2 5、 no. 3 6 ,1 no. 1 4 and 1 no. 1 4-10 and 1 , 1 no. 1 4 and 1 no. 1 4-10 and 1 ;2 no. 2 5 no. 2 5-10 and 。3 no. 3 6 and 2 no. 3 6-10 and 2 , 3 no. 3 6 and 2 no. 3 6-10 and 2 ;1、 and 2、,2 、 and 3、。 Embodiment 2

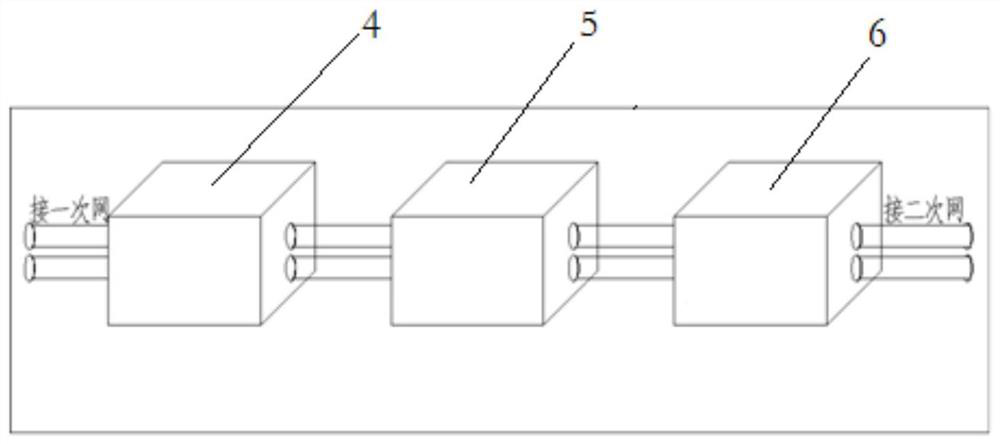

[0080] Embodiment one: if figure 1 As shown, the first modular box 4 of the heat exchange control unit, the second modular box 5 of the water quality assurance unit, and the third modular box 6 of the distribution balance unit are arranged horizontally in sequence, and the heat exchange control assembly 1 The water inlet end is connected to the water outlet end of the municipal heating primary network through the first interconnection node 4-10 reserved on the first modularized box body 4 and the municipal heating primary network, and the water outlet end of the heat exchange control component 1 passes through the first The first interconnection node 4-10 reserved on the modular box body 4 and the municipal heating primary network is connected to the water inlet end of the municipal heating primary network; the water inlet end of the water quality assurance component 2 passes through the second modular box The second interconnection node 5-10 of the tap water pipe network rese...

Embodiment 3

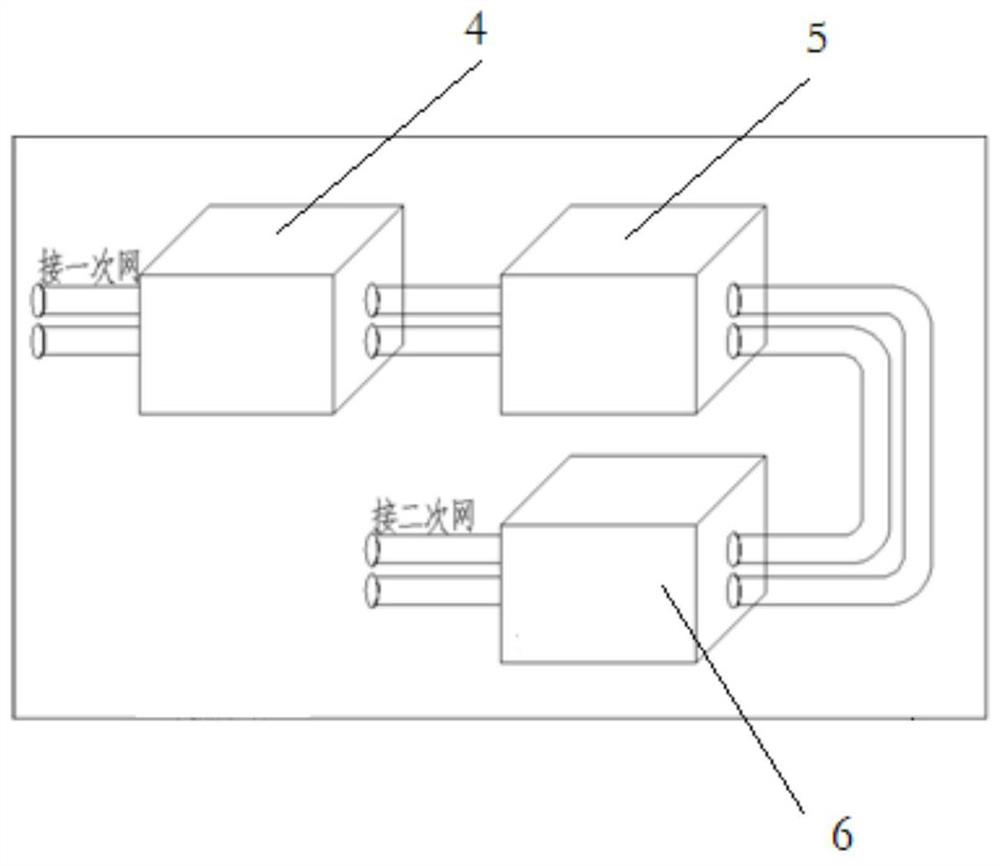

[0081] Embodiment three, such as image 3 As shown, the first modularized box 4 of the heat exchange control unit is connected to the second modularized box 5 of the water quality assurance unit through a straight pipe, and the second modularized box 5 of the water quality assurance unit is connected to the distribution unit through a C-shaped pipe. The third modular box 6 of the balance unit is connected, and the connection mode of the heat exchange control component 1 , the water quality assurance component 2 and the distribution balance component 3 is the same as that of the first embodiment.

[0082] Further, the heat exchange control assembly 1 includes a plate heat exchanger 1-1 and a circulating water pump 1-2, wherein the plate heat exchanger 1-1 includes a high temperature side water inlet end, a high temperature side water outlet end / low temperature side inlet The water end and the low temperature side water outlet, the low temperature side water inlet end of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com