Construction site residual brick picking and refining device and using method

A technology for residual bricks and construction sites, which is applied in the field of residual brick picking and refining devices on construction sites, can solve the problems of inability to achieve linkage, high device cost, and unfavorable savings in brick collection and crushing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0049] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

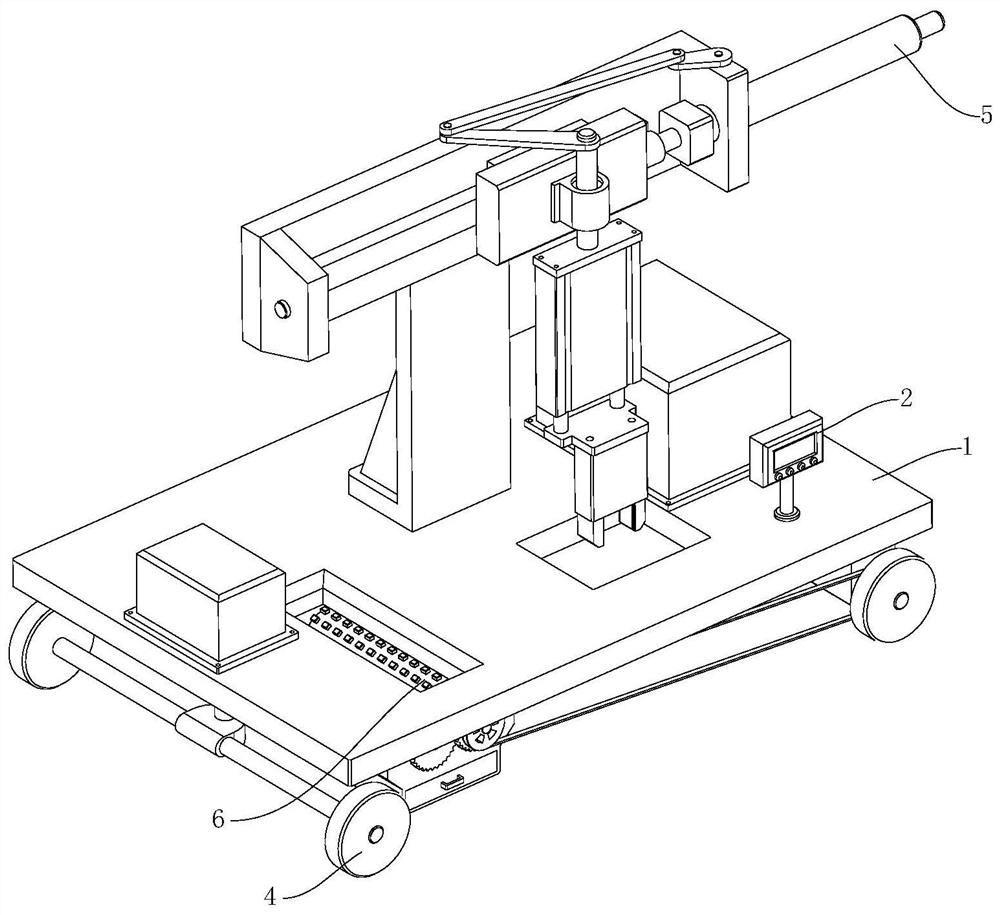

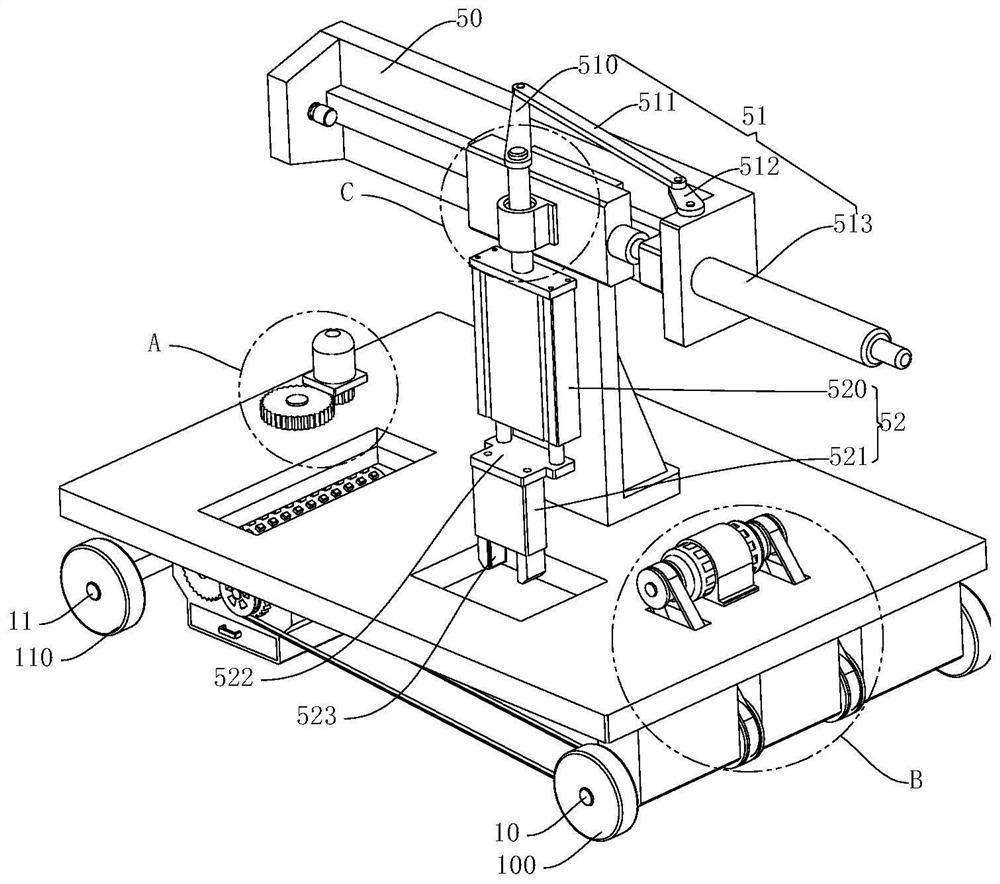

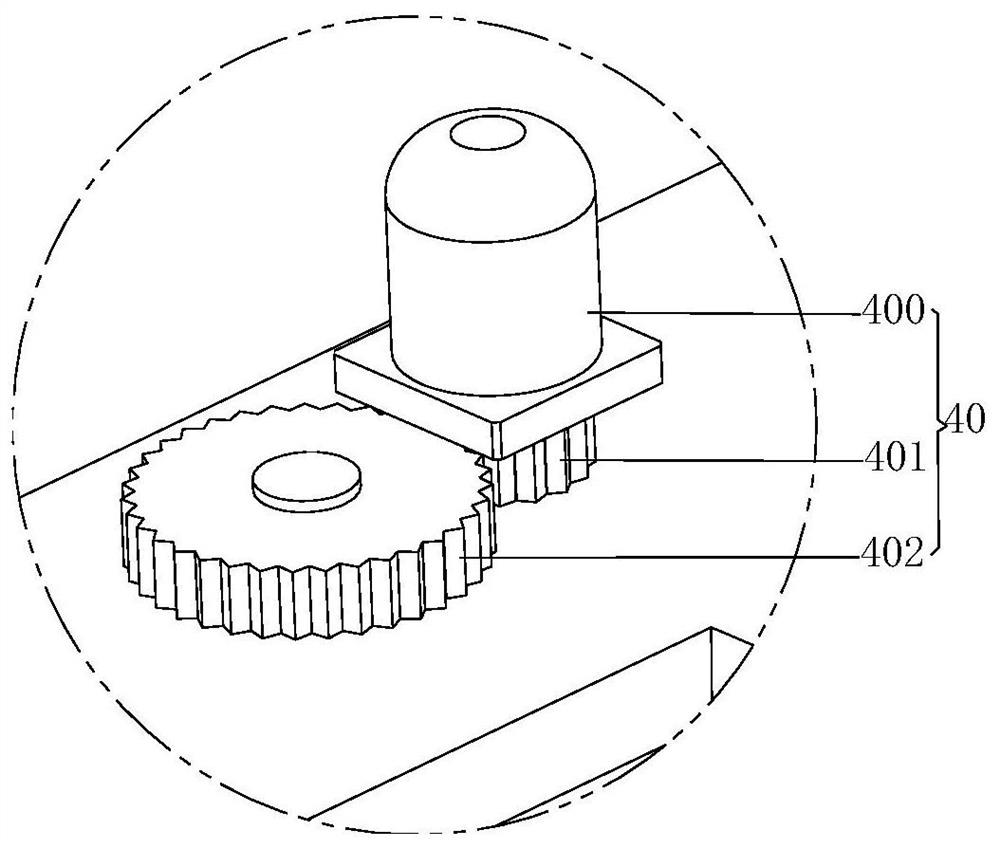

[0050] refer to Figure 1 to Figure 9 The device for picking and refining residual bricks on a construction site includes a chassis 1, a controller 2, a wide-angle camera 3, a traveling mechanism 4, a picking mechanism 5 and a rolling mechanism 6, and the controller 2 is fixed on the chassis 1, the wide-angle camera 3 is installed on the bottom of the chassis 1, and the traveling mechanism 4 is arranged on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com