Guardrail ash removal device for expressway

A cleaning device and expressway technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of slow cleaning speed and heavy cleaning workload, and achieve the effect of reducing workload and improving cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

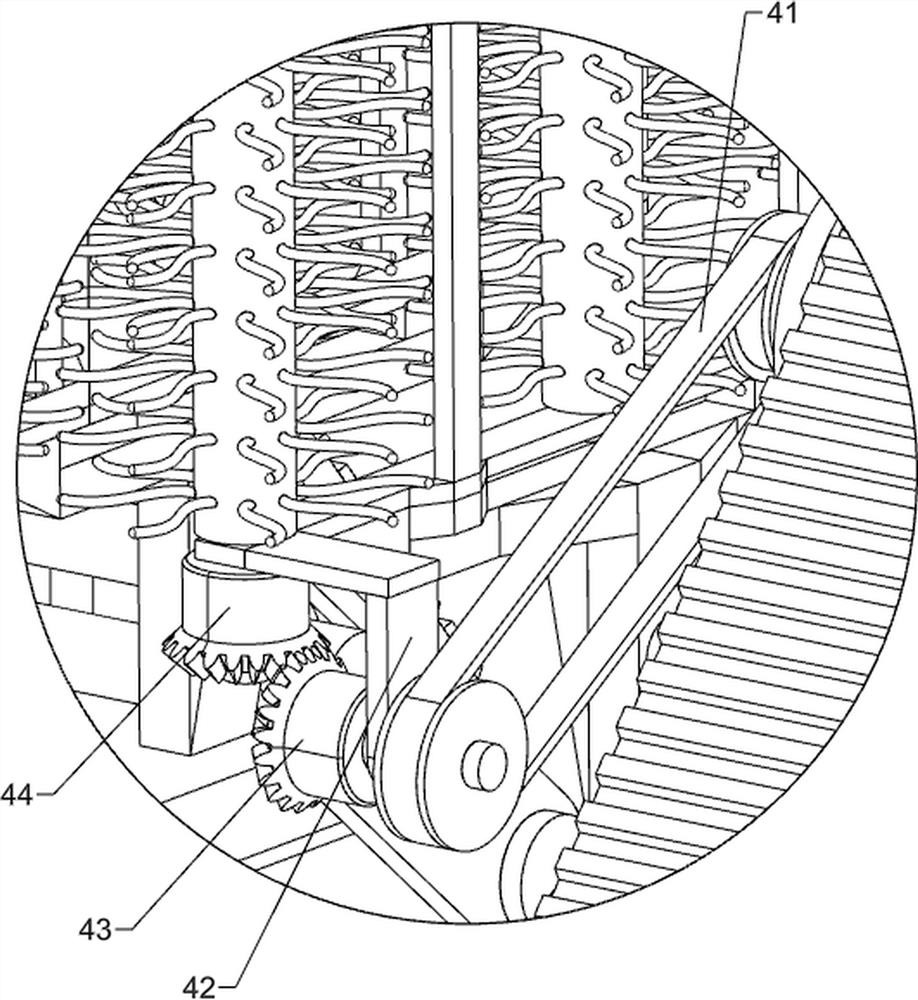

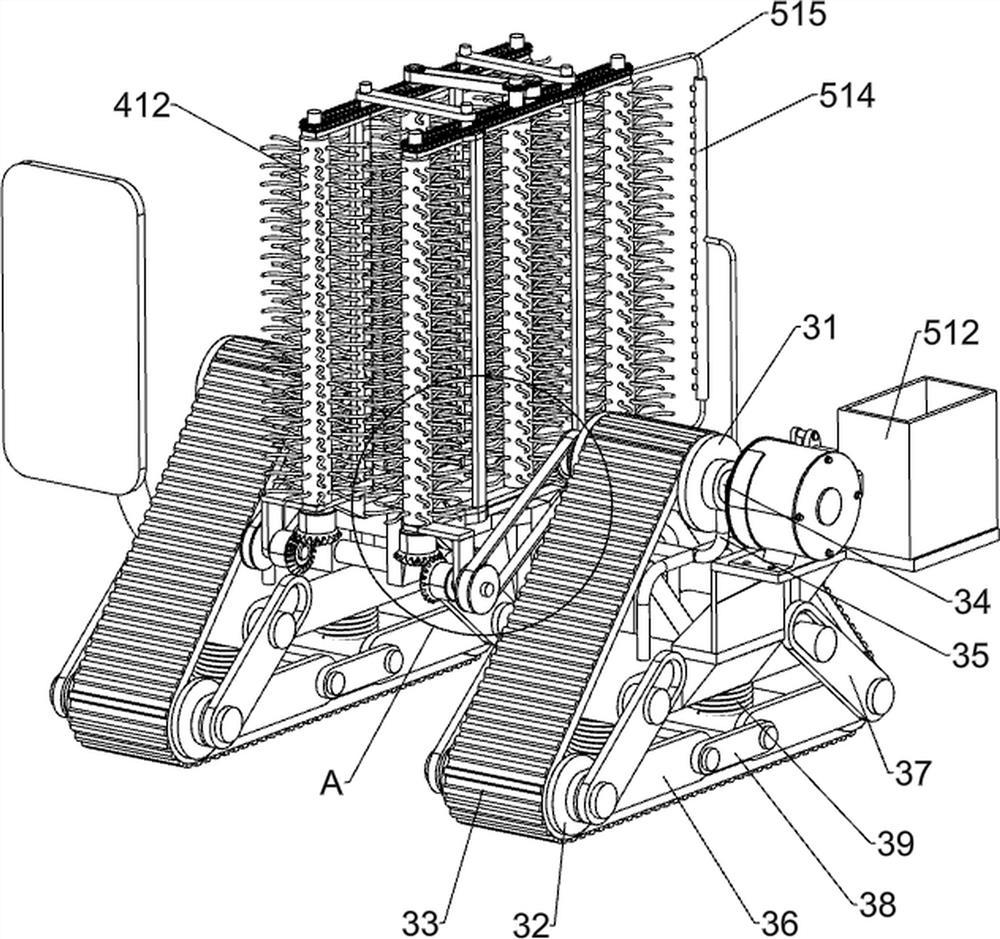

[0023] A guardrail dedusting device for expressways, such as Figure 1-2 and Figure 4-5 As shown, it includes a mounting frame 1, a servo motor 2, a moving mechanism 3 and a cleaning mechanism 4. There are two mounting frames 1, and the left part of the left mounting frame 1 is equipped with a servo motor 2. The moving mechanism 3 is connected with the cleaning mechanism 4, and the moving mechanism 3 is connected with the cleaning mechanism 4, and the moving mechanism 3 is connected with the servo motor 2 through transmission.

[0024] The moving mechanism 3 includes a driving wheel 31, a driven wheel 32, a crawler belt 33, a first transmission shaft 34, a first fixed collar 35, a support base plate 36, a limit plate 37, a first sliding connecting plate 38 and a support spring 39. The lower part of the frame 1 is connected with a first fixed collar 35, the first fixed collar 35 is connected with a first transmission shaft 34 in a rotational manner, the first transmission sha...

Embodiment 2

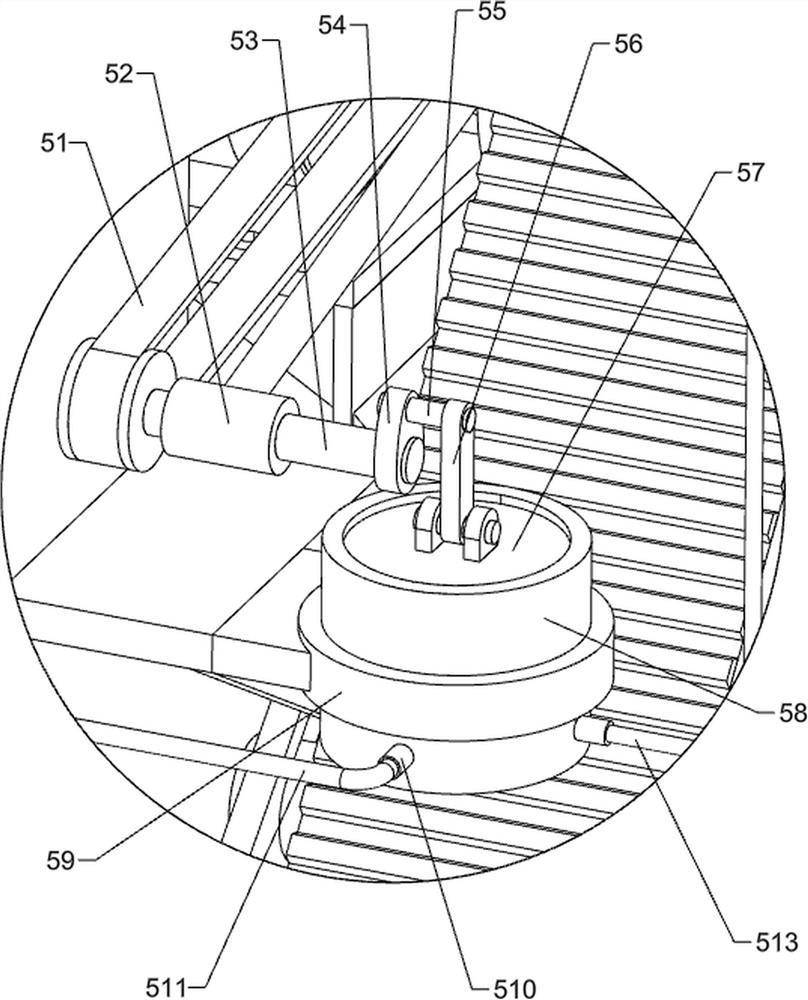

[0028] On the basis of Example 1, such as Figure 1-3 and Figure 6 Shown, also comprise water spraying mechanism 5, and water spraying mechanism 5 comprises the 3rd transmission belt set 51, the second fixed collar 52, the second transmission shaft 53, cam 54, connecting rod 55, sliding connecting rod 56, piston 57, compression cylinder 58, second fixed frame 59, one-way valve 510, water inlet pipe 511, water storage bucket 512, drainpipe 513, atomizing nozzle 514 and fixed rod 515, on the left side first fixed collar 35, be connected with The second fixed collar 52, the second fixed collar 52 is rotationally connected with the second transmission shaft 53, the third transmission belt set 51 is connected between the second transmission shaft 53 and the first transmission shaft 34 on the left side, The right end of the two drive shafts 53 is connected with a cam 54, the eccentric position of the cam 54 is rotatably connected with a connecting rod 55, the connecting rod 55 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com